- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

14000 KG

-

Power (kW):

-

37.5

-

input power:

-

30 KVA

-

output power:

-

20KW

-

HF output:

-

2 output

-

oscillation:

-

6.78MHz

-

Tuning Mode:

-

Variable capacitor

-

cooling mode:

-

force wind cooling

-

quantity of hyfraulic cylinders:

-

2 pieces

-

working size:

-

1600*800mm

-

hydraulic cylinder stroke:

-

600mm

-

hydraulic system rated pressure:

-

25Mpa

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SAGA

-

Machine Type:

-

woodworking Hot press

-

Weight (KG):

-

14000 KG

-

Power (kW):

-

37.5

-

input power:

-

30 KVA

-

output power:

-

20KW

-

HF output:

-

2 output

-

oscillation:

-

6.78MHz

-

Tuning Mode:

-

Variable capacitor

-

cooling mode:

-

force wind cooling

-

quantity of hyfraulic cylinders:

-

2 pieces

-

working size:

-

1600*800mm

-

hydraulic cylinder stroke:

-

600mm

-

hydraulic system rated pressure:

-

25Mpa

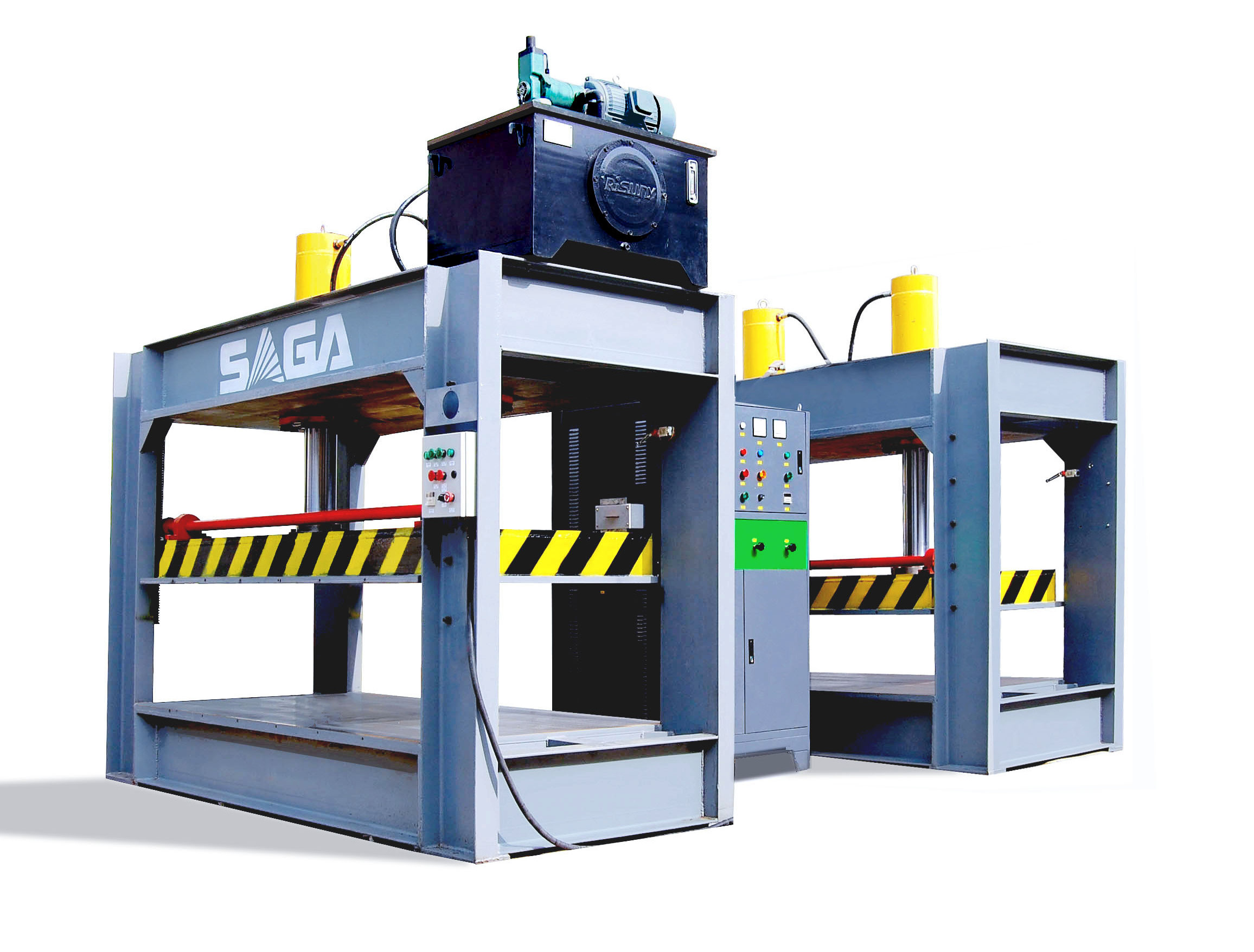

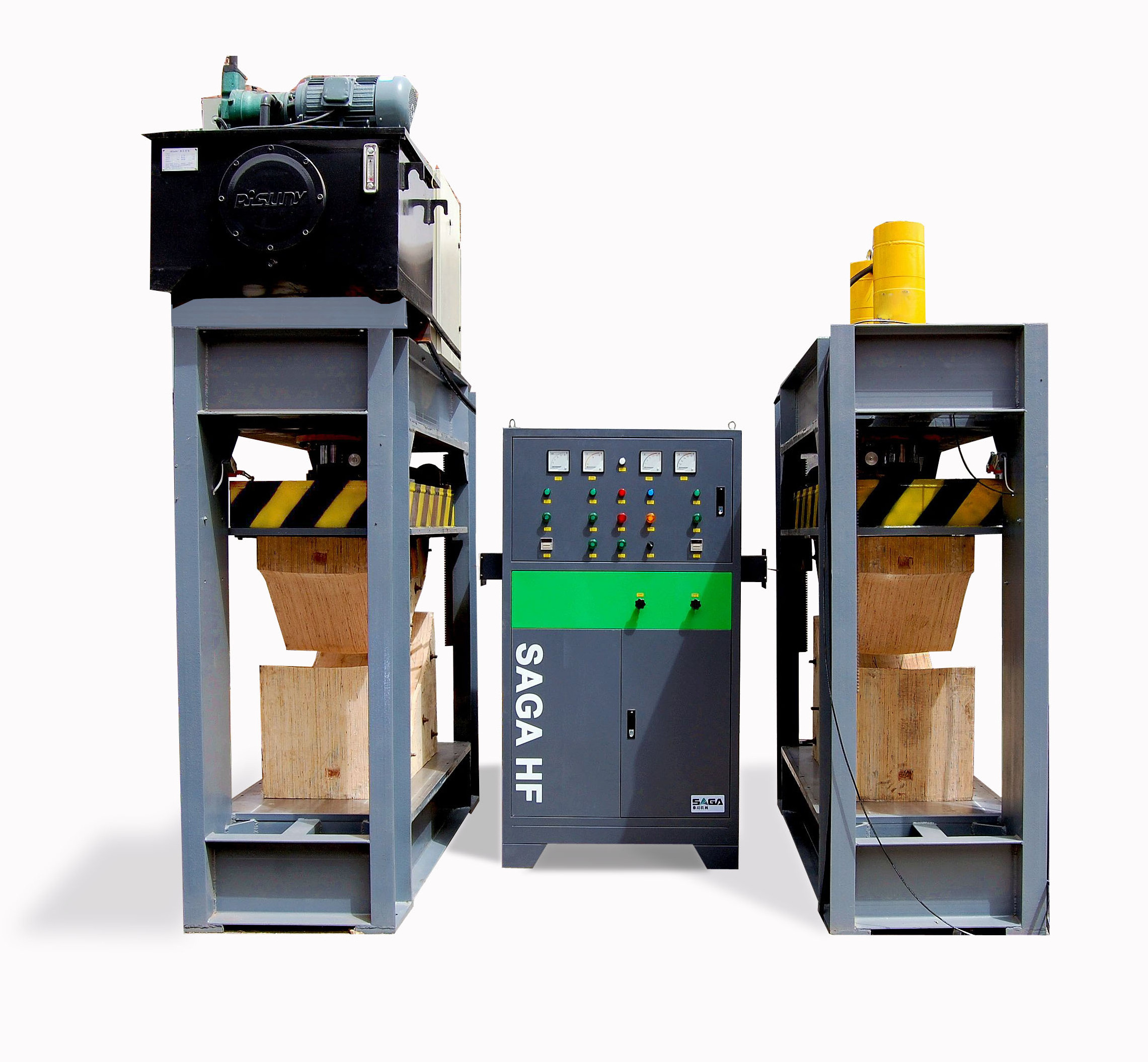

SAGA PRESS

SAGA is well known as high standard HF/RFmachinery for woodworking, SAGA press, is stand for heavy duty durable machine with stable running.

High frequency curved plywood press applies high frequency generator to hydraulic press, by mold and electrode, it transfers

high frequency power to work piece to achieve the function of fast gluing and forming.

High frequency press is suitable for bent plywood chair, bent or arc plywood for furniture or bed or other bent plywood products,

like cloth hanger or surface of musical instrument.

1. Fast and unfirm heating;

2. Bending shape is stable, not easy to change delamination;

3. High frequency power is selective heating power, it concentrates only on water or glue, wood does not consume high frequency power, HF heating is effective and power saving.

4. Wooden or MDF mold used, much more economic than metal mold if shape is frequently changed.

|

PARAMETER of YX120-SA

|

|

|

|

|||

|

HIGH FREQUENCY GENERATOR 20KW

|

|

ONE DIRECTION PRESS 80 TON

|

|

|||

|

Power

|

380V, 3Ph, 220V, 1Ph, 50Hz

|

Power

|

380V, 3Ph, 220V, 1Ph, 50Hz

|

|||

|

Input Power

|

30KVA

|

Total Hydraulic Pressure

|

120 ton

|

|||

|

Output Power

|

20KW

|

Vertical Hydraulic Pressure

|

120 ton

|

|||

|

HF Output

|

2 output

|

Quantity of Hydraulic Cylinders

|

2 pieces

|

|||

|

Oscillation

|

6.78 MHz

|

Working Size

|

1600*800mm

|

|||

|

Protection

|

Overload protection, wind cooling pressure detection, filament 2 stages stars, lose phase protection

|

Opening Between Up and Down Platen

|

1100mm

|

|||

|

Tuning Mode

|

Variable capacitor

|

Hydraulic Cylinder Stroke

|

600mm

|

|||

|

Cooling Mode

|

Force wind cooling

|

Hydraulic System Rated Pressure

|

25Mpa

|

|||

|

Ouerall Size

|

(L*W*H)1000*850*1850mm

|

Over Size

|

(L*W*H)2300*800*2200mm

|

|||

|

Gross Weight

|

700KGS

|

Gross Weight

|

6500KGS

|

|||

|

MB6213B Automatic Two Rollers Glue Spreader

|

|

|

|

Max Working Width

|

1300mm

|

|

|

Max Working Thickness

|

120mm

|

|

|

Dia. Of Spreading Rollers

|

Φ185mm

|

|

|

Operation Height

|

810mm

|

|

|

Feed Speed

|

20m/min

|

|

|

Motor Power

|

0.4KW

|

|

|

Features and Specification of Basic Model

|

|

|

|

|||

|

Model

|

|

HYB-2Y

|

|

|||

|

Features

|

|

|

|

|||

|

1. DSP hand control system

|

|

|

|

|||

|

2. 6kw China air cooling spindle 2 pieces

|

|

|

|

|||

|

3. Two vacuum chuck and 5.5kw water cooling vacuum pump

|

|

|

|

|||

|

4. Stepped motor and yako 2811 driver

|

|

|

|

|||

|

5. Taiwan hiwin spuare rails

|

|

|

|

|||

|

6. Taiwan ball screw

|

|

|

|

|||

|

7. 7.5kw fulling inverter

|

|

|

|

|||

|

8. Type 3 software

|

|

|

|

|||

|

9. 380V, 3 phase, 50 Hz

|

|

|

|

|||

|

Warranty

|

|

1 year

|

|

|||

|

Payment

|

|

40% T/T deposit in advance, shippment after recieving balance payment

|

|

|||

|

Delivery time

|

|

35 days

|

|

|||

|

Overall size

|

|

3000*2250*1700mm

|

|

|||

|

Weight

|

|

900kgs

|

|

|||

1.What is your price term and payment term?

We offer FOB, CIF, CNF EXW price, we accept TT/LC or other negotiate.

In stock:

100% payment;

Not in stock:

30-40% deposit for confirm the order, rest is paid before shipment, some customized machine may need 50% deposit.

2.How long for delivery?

Some standard machine or commercial machine, always in stock, for high value machine or customized machine, may takes 30-40days production.

3.After sale and warranty?

Most machine got 1 year warranty except some consumption spare, all spare within warranty period is free for change, in the condition that machine is running according to the manual book(saga got rights for explain).

4.Installation for complex machine.

We have 20 years of experience for installation all over the world for big and complex machine, customer response for food and living as well as transport, some area may be served by our agent. For commercial machine, we will do our best to offer installation guiding video.

5.Free spare parts for change.

Most of our machine use international standard, especially electric spare parts, if not, we offer free spare parts to avoid any urgent condition to minimize risk of downtime.

6.Safety for the machine and packing.

We have mature experience for sea transport packing, for some irregular shape machine, we will do special fix and tight on container to avoid any risk of any broken.