- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

6755x970x1650mm

-

Power (kW):

-

16.5

-

Weight (KG):

-

2450 kg

-

Panel Feed Speed(m/min):

-

23m/min

-

Panel Length:

-

150mm

-

Panel Thickness:

-

80mm

-

Edge Thickness:

-

0.4-3mm

-

Feeding Speed:

-

23m/min

-

X Working Area:

-

1300mm

-

Y Working Area:

-

2500mm

-

Z Working Area:

-

200mm

-

Wood Router Working Speed:

-

25000mm/min

-

Traveling Positioning Accuracy:

-

±0.05mm

-

Production capacity:

-

80-100 pcs standard size board(1220*1440 mm )/8 hours

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ZICAR

-

Voltage:

-

220V/380V or Customized

-

Dimension(L*W*H):

-

6755x970x1650mm

-

Power (kW):

-

16.5

-

Weight (KG):

-

2450 kg

-

Panel Feed Speed(m/min):

-

23m/min

-

Panel Length:

-

150mm

-

Panel Thickness:

-

80mm

-

Edge Thickness:

-

0.4-3mm

-

Feeding Speed:

-

23m/min

-

X Working Area:

-

1300mm

-

Y Working Area:

-

2500mm

-

Z Working Area:

-

200mm

-

Wood Router Working Speed:

-

25000mm/min

-

Traveling Positioning Accuracy:

-

±0.05mm

-

Production capacity:

-

80-100 pcs standard size board(1220*1440 mm )/8 hours

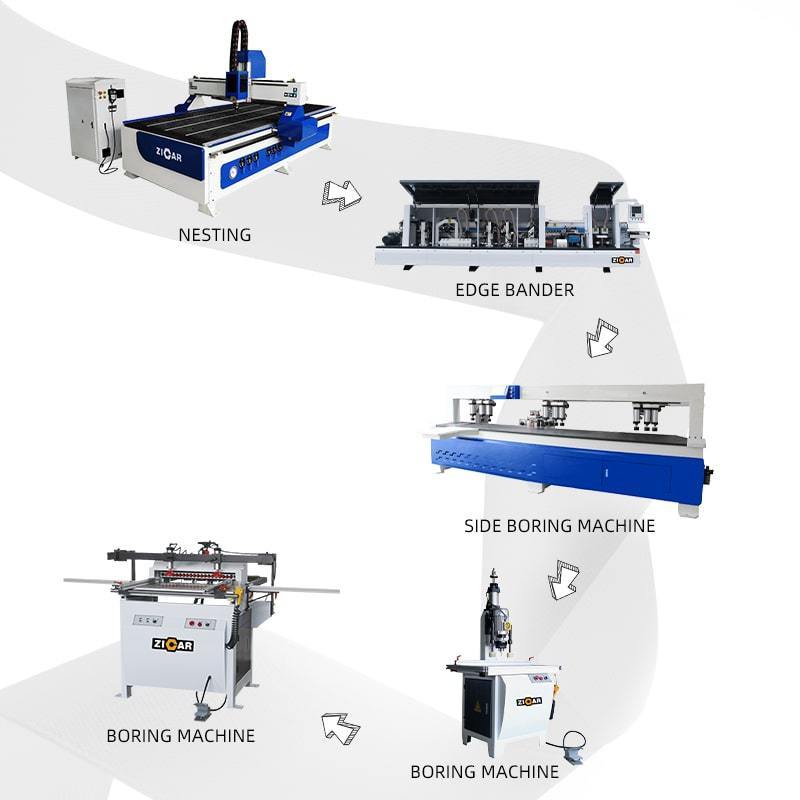

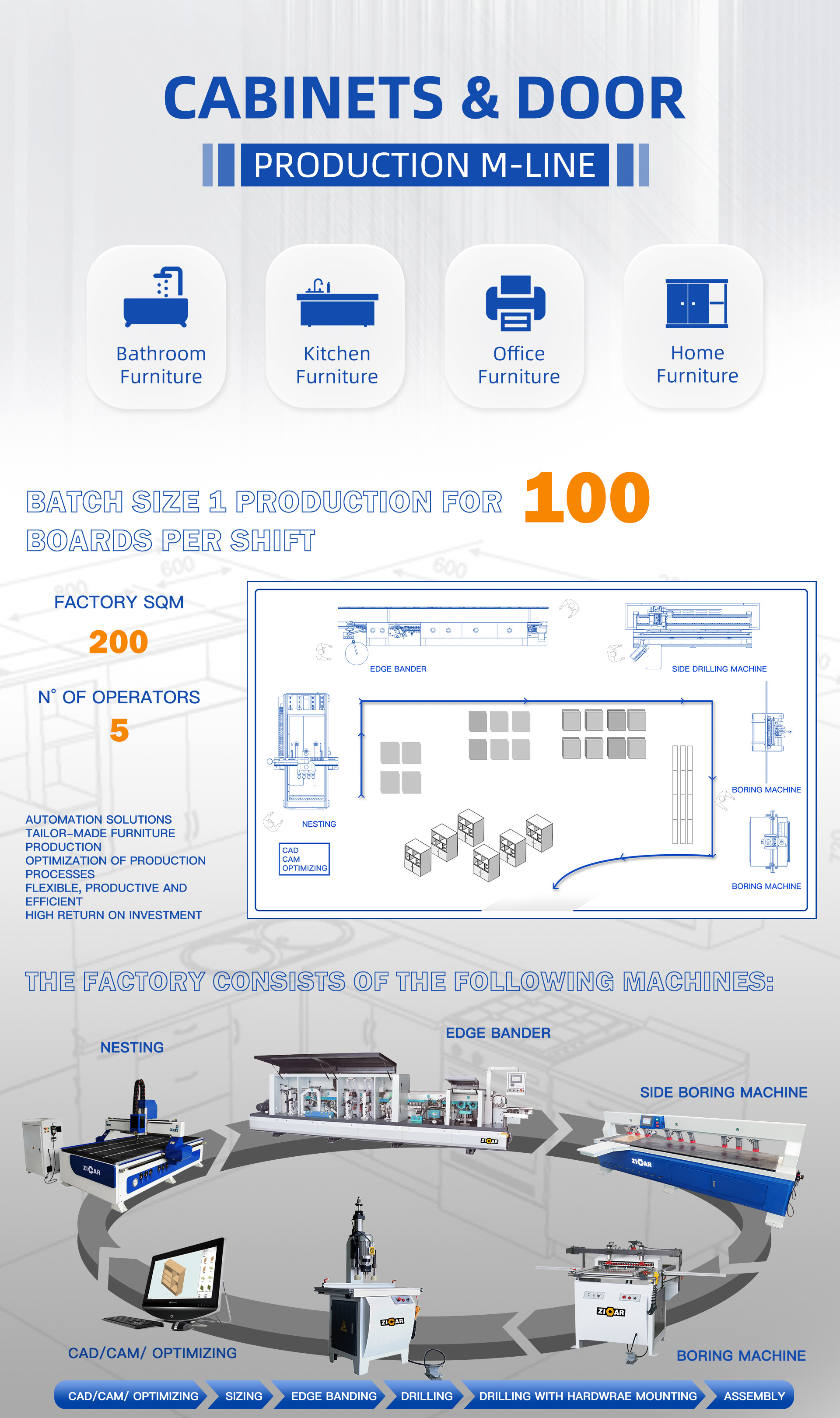

● The production line is suitable for some small and medium-sized furniture factories.

● Space requirement is about 10(Width)x 18(Length)square meters.

● Each machine is simple and easy to operate.

● This production line can reach up to 80-100 pieces standard size board(1220*1440 mm ) within 8 hours, which could improve working efficiency.

● Only 5-6workers are needed, saving labor costs.

● Used in kitchen furniture, office furniture and other furnitures.

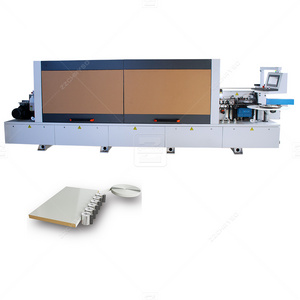

HIGH SPEED EDGE BANDING DETAILS

●

MF50G (5 functions): Gluing, End Cutting, Fine Trimming, Scraping, Buffing.

● MF50F (8 functions) : Pre-milling, Gluing, End Cutting, Rough Trimming, Fine Trimming, Corner Trimming, Scraping, Buffing .

|

Model

|

MF50F (8 functions)

|

|

Panel Length

|

Min.150mm

|

|

Panel Width

|

Min. 80mm

|

|

Panel Thickness

|

10-60mm

|

|

Edge Thickness

|

0.4-3mm

|

|

Feeding Speed

|

15~23m/min

|

|

Working Pressure

|

0.6mpa

|

|

Net Weight

|

2450kg

|

|

Total Power

|

16.5kw

|

|

Overall Size

|

6755x970x1650mm

|

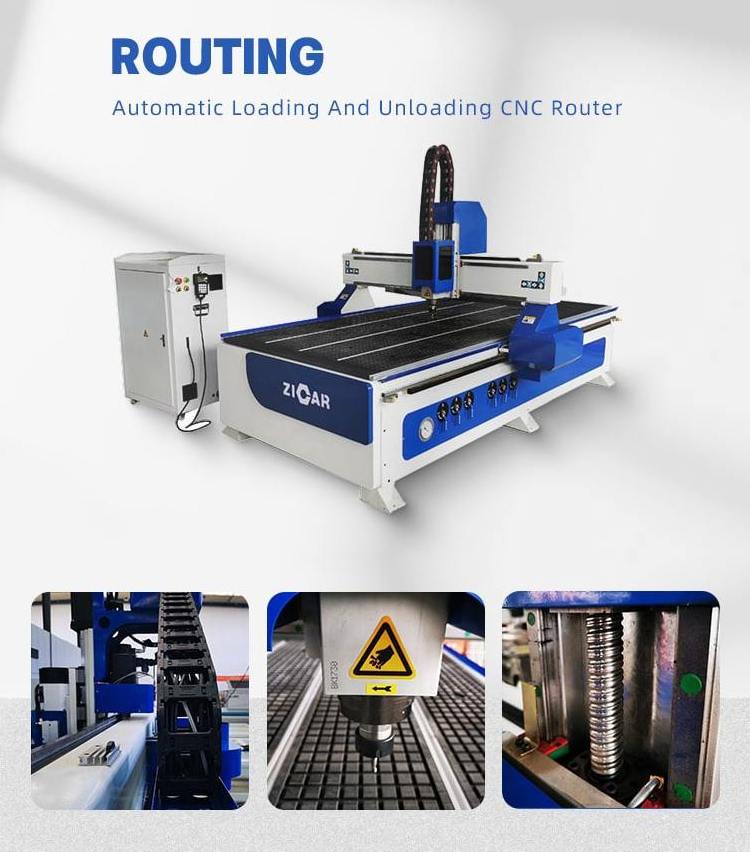

SMART CUTTING DETAILS

●

Increase Dust-free vacuum efficiency by 80%, No1 revolutionary dust vacuum designin the industry and have won praise from many

customers.

● 2D and 3D processing with router and knife tools.

● It is equipped with high accuracy gear rack, and the X/Y-axis adopt high accuracy grinding rack for transmission. Assured high stability and processing accuracy.

● Be compatible with many CAD/CAM software like type3/Art-cam/Casmate/Proe/UG/Artgrave etc.

|

X Working Area

|

1300mm

|

|

Y Working Area

|

2500mm

|

|

Z Working Area

|

200mm

|

|

Traveling Positioning Accuracy

|

±0.05mm

|

|

Repositioning Positioning Accuracy

|

±0.05mm

|

|

X, Y, Z Structure

|

German gear wheel for XY axis / Taiwan TBI ball screw for Z axis

|

|

Max. Power Consumption(Without spindle)

|

1.84kw

|

|

Max. Rapid Travel Rate

|

45000mm/min

|

|

Max. Working Speed

|

25000mm/min

|

|

Spindle Power Motor

|

3kw water cooling spindle

|

|

Spindle Speed

|

0-24000r/min

|

|

Drive Motor

|

Stepper motor&Leadshine driver

|

|

Working Voltage

|

AC220V/380V 50/60Hz or customized

|

|

Control System

|

DSP handle

|

CNC DRILLING DETAILS

●

For horizontal drilling of various wood-based panels, solid wood panels, semi-solid wood panels

.

|

Spindle

|

HQD 2.2kw air cooling*2

|

|

Guide

|

20mm guid rail

|

|

Frequency Converter

|

2.2kw MIGE inverter

|

|

Drive Motor

|

DORNA servo motor

|

|

Run Instruction

|

TG765-XT-C

|

|

Operating System

|

MIGE system

|

|

Tool Changing Form

|

Auto change tools

|

|

Working Table Size

|

300*2750mm

|

|

Converter

|

DIFF-OC

|

|

LaserInfrared Ray

|

Germany camewrght

|

APPLIED INDUSTRIES

Sign Making

Door Making

Furniture Making

Cabinet Making

ABOUT ZICAR

PACKING&SHIPPING

FAQ

1.Our Payment Way?

L/C and T/T or other ways.

2.Delivery Time?

30 days after downpayment.We have our own forwarder and we have long term cooperation with each other and have closely relationship with each other.so there is no problem in shipment.

3.Our Warranty?

(1)One year guarantee from the delivery date of this machine under the normal operation of one shift per day.

(2)We will be responsible for the maintenance of damaged part which is under normal situation during warranty period, and all the round-trip courier transportation cost of damaged/repaired replacement parts in warranty period should be borne by the buyer. Wearing parts are not included.

(3)24 hour technical support by email or calling.

(4)User-friendly English manual for machine using and maintaining.

4.Our Services?

(1)One-stop service, meet needs of the customers from individuals to international companies.

(2)OEM service accepted.

(3)Separate trading office: Jaya Trading with 30 experienced sales offering full scale service.

(4)After sale Service: experienced and knowledgeable team of technical support, provide engineer oversea service.

Hot Searches