- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

According to capacity

-

Weight:

-

According to capacity

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Free spare parts, Online support, Field installation, commissioning and training, Field maintenance and repair service

-

Advantages:

-

High quality, competitive price

-

Manufacturer:

-

casting grinding balls and forged grinding balls

-

Name:

-

Low Cr Balls,Middle Cr Balls,Normal High Cr,Special High Cr

-

Keywords:

-

Ball mill ball

-

Production Capacity:

-

According to capacity

-

Voltage:

-

According to capacity

-

Certification:

-

ISO9001-2000

Quick Details

-

Capacity(t/h):

-

0.5-12

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

Ball mill ball DESEN

-

Dimension(L*W*H):

-

According to capacity

-

Weight:

-

According to capacity

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Free spare parts, Online support, Field installation, commissioning and training, Field maintenance and repair service

-

Advantages:

-

High quality, competitive price

-

Manufacturer:

-

casting grinding balls and forged grinding balls

-

Name:

-

Low Cr Balls,Middle Cr Balls,Normal High Cr,Special High Cr

-

Keywords:

-

Ball mill ball

-

Production Capacity:

-

According to capacity

-

Voltage:

-

According to capacity

-

Certification:

-

ISO9001-2000

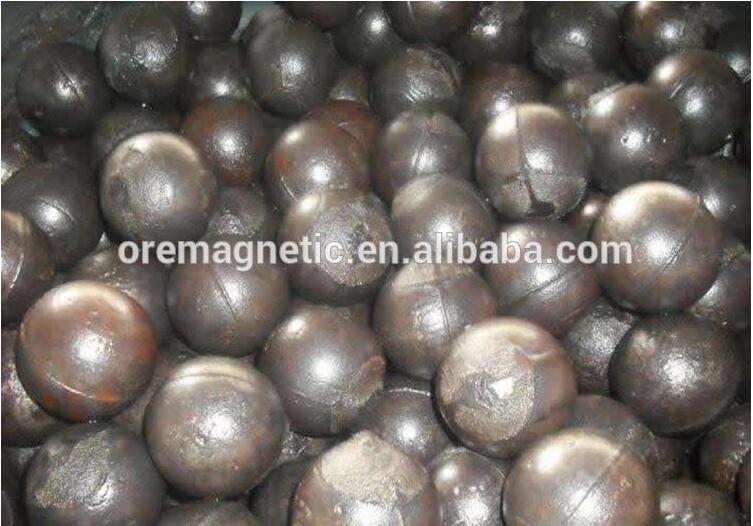

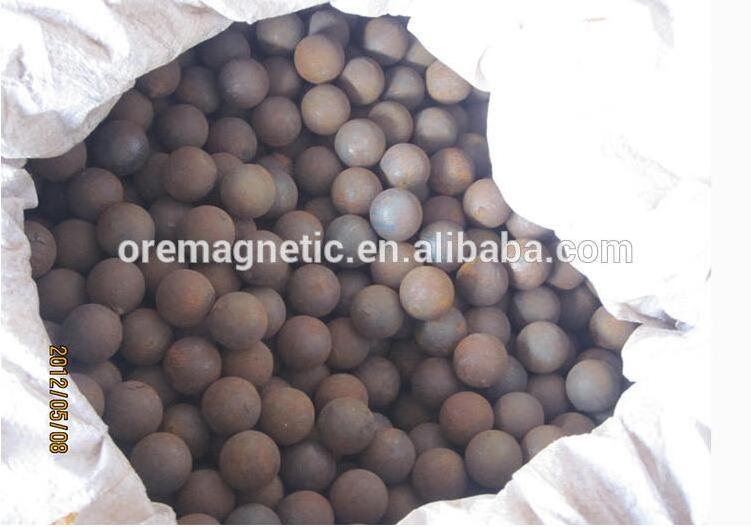

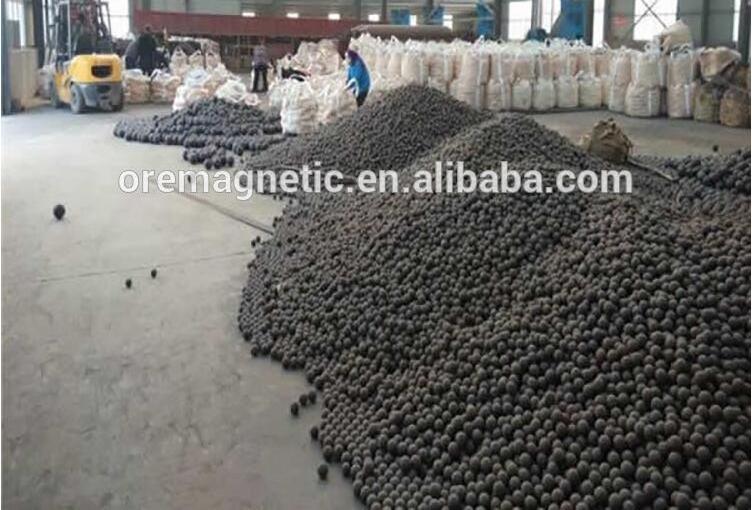

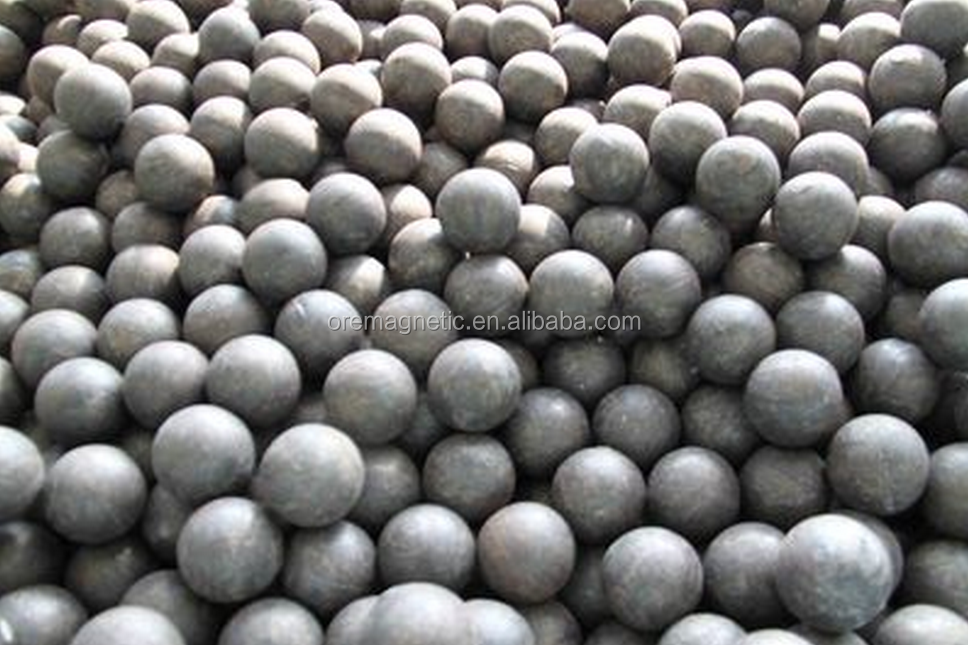

Ball Mill Steel Ball

Specification

1)

High Hardness: Surface hardness:

HRC60-68 HRC, volume hardness HRC60-65.

2)

High Impact Toughness:

The impact toughness of our grinding balls is more than 12 J / cm2.

3)

Low Broken Rate:

the actual broken rate is not higher than 1%.

4)

Good wear-resistant and lower wear rate.

Chemical Elements

|

Name |

Chemical Elements (%) |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Cu |

P |

S |

|

|

Low Cr Balls |

2.2-2.5 |

≤1.2 |

0.5-1 |

0.8-1.8 |

0.6-1 |

≤1 |

≤0.05 |

≤0.05 |

|

Middle Cr Balls |

2.2-3.3 |

≤1.2 |

0.5-1 |

3-6 |

0.6-1 |

≤1 |

≤0.05 |

≤0.05 |

|

Normal High Cr |

1.6-3.3 |

≤1.0 |

0.5-1 |

10-13 |

0.8-1 |

≤0.6 |

≤0.05 |

≤0.05 |

|

Special High Cr |

2.0-3.3 |

≤1.o |

2.1-3 |

15-23 |

0.8-1 |

≤0.6 |

≤0.05 |

≤0.05 |

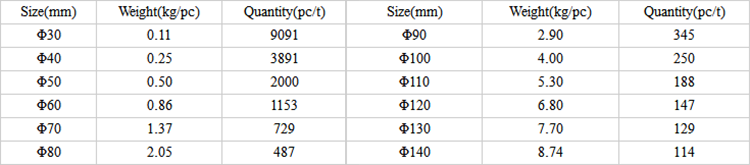

Technical Parameters

Ball mill steel balls

Company I ntroduction

We(Xi’an Desen Mining Machinery Equipment Co.,Ltd.) is dedicated to providing separation production line for Marine placer, Tungsten ore, Magnetite, chromite, zircon sand, rutile, monazite, Tantalite, Manganese ore and others Non-Metal ores Etc.

Our Client Visit

On-site Working

Our Service

Pre-sale services: enthusiasm

We will provide you with the prior plan, process flow design and production equipment in line with your special

needs.

Sale services: servant

We will send technicians to you for guiding the equipment installation and commissioning and staff training.

After-sale services: faithfulness

We will regularly return visit to customers for establishing a long-term and friendly relationship.

Service Commitment

We provide one-year warranty to make sure your machine work well. We have spare parts of the very machine

in stock all the time which means the replacements can be sent to you timely.

FAQ

1. Q: Are you professional? Do you have ever engaged in the implementation of the overseas mining projects?

A: Yes, we have professional mineral separation team in this industry. Our engineers who perennial activities in South-east Asia, Eastern Europe, Africa and so on, they are expert at the Gold ore, Iron ore, Manganese ore, Tantalum & Niobium, Tungsten and other extraction production.

2. Q: Now we plan to make the production line separation and purification of this mineral. How to deal with it? What type of equipment we need to use?

A: According to mineral information and mining conditions from customers, our engineer design the best mineral processing line and the appropriate equipment to meet the specific needs of customers.

3. Q: If we give this order to your company, what kind of service you can offer?

A: First of all, if needed, our engineers will go to your mining site for field investigation to make the best designing scheme.

After the equipment arrived, we will send engineers to stationed in mine site to conduct the construction of the project, the installation and debugging and the staff training and ensuring the production are always working normally.

4. Q: The technology you designed need water? How much water it will need? What will do if there is a water shortage in our mine site?

A: For this kind mineral, we have dry and wet two different mineral separations. Our engineers will choice the best craft and equipments by the actual conditions that ensure the production line working normal in lack water or less water condition.

5. Q: What promises do you have about the quality of the equipment?

A: Warranty Time: one year. Meanwhile, we will provide a list of consumable parts, and can priority to provide you with adequate vulnerable parts.