- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

10 years

-

Place of Origin:

-

Shanxi, China

-

Brand Name:

-

SYI

-

Model Number:

-

Fittings for PVC pipes

-

Body:

-

Ductile iron grade 500-7/ 450-12 in accordance with ISO 1083

-

Fluid Temperature:

-

0°C-50°C, excluding frost

-

Pressure:

-

100% Hydraulic Test

-

Name:

-

Fittings for PVC Pipes

Quick Details

-

Technics:

-

Casting

-

Shape:

-

Equal

-

Head Code:

-

Round

-

Warranty:

-

10 years

-

Place of Origin:

-

Shanxi, China

-

Brand Name:

-

SYI

-

Model Number:

-

Fittings for PVC pipes

-

Body:

-

Ductile iron grade 500-7/ 450-12 in accordance with ISO 1083

-

Fluid Temperature:

-

0°C-50°C, excluding frost

-

Pressure:

-

100% Hydraulic Test

-

Name:

-

Fittings for PVC Pipes

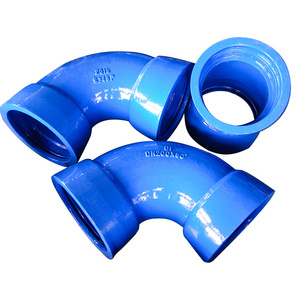

Ductile Iron Compact Fittings For PVC Pipes EN 12842 ISO 2531 EN 545 EN598 For Water Or Sewerage Pipeline Projects

Product Description

SYI Compact Fittings for PVC Pipes

is the Newest design, most light, most competitive ductile iron pipe fittings for PVC pipes,from DN80 to DN600 according to EN 10842, ISO 2531, EN545, and EN 598 for water or sewerage pipeworks, with the coating of Zinc and Black Bitumen coating, Red/Blue Epoxy coating, or PU (polyurethane) coating.

|

Material:

Fitting

:Ductile iron grade 500-7/ 450-12 in accordance with ISO 1083.

Gasket:Rubber E.P.D.M./NBR/SBR in accordance with EN 681.1

|

|

|

|

Working Pressure: 16 Bar or 250 PSI

|

|

|

|

Fluid Temperature:0°C-50°C, excluding frost

|

|

|

|

Coating

|

|

|

|

External coatings

|

Internal coatings

|

|

|

zinc + bitumen painting

liquid epoxy resin painting epoxy applied by FBE according to customers' requirements |

cement mortar lining

liquid epoxy resin painting epoxy applied by FBE according to customers' requirements |

|

|

Reference Rules:Dimensions and testing in accordance with ISO 2531 / EN 545 and EN 12842

|

|

|

Used for jointing the PVC pipes. Fittings can be assembled by pushing the spigot through the gasket in

the socket of the mating component.

the socket of the mating component.

Feature:

1.PVC pipe is characterized by thin thickness, light weight, sealing surface can not be machined, only by advanced casting methods to meet the requirements.

2.Through our efforts, SYI COMPACT PVC Pipe Fittings have been formed a new PVC pipe fittings with production line and coated sand technology to achieve high-quality casting surface, perfect sealing effect, more reasonable structure advantage and more market competition.

1.PVC pipe is characterized by thin thickness, light weight, sealing surface can not be machined, only by advanced casting methods to meet the requirements.

2.Through our efforts, SYI COMPACT PVC Pipe Fittings have been formed a new PVC pipe fittings with production line and coated sand technology to achieve high-quality casting surface, perfect sealing effect, more reasonable structure advantage and more market competition.

|

SYI Compact Fittings for PVC pipes Pattern List

|

|

|

|

|||

|

SYI Series No.

|

OD

|

od

|

DN

|

|||

|

Flange Socket

|

|

|

|

|||

|

EKS7560

|

75

|

|

60

|

|||

|

EKS7580

|

75

|

|

80

|

|||

|

EKS9080

|

90

|

|

80

|

|||

|

EKS110100

|

110

|

|

100

|

|||

|

EKS160150

|

160

|

|

150

|

|||

|

EKS225200

|

225

|

|

200

|

|||

|

Double socket Taper

|

|

|

|

|||

|

MMRKS11090

|

110

|

90

|

|

|||

|

MMRKS16090

|

160

|

90

|

|

|||

|

MMRKS160110

|

160

|

110

|

|

|||

|

MMRKS22590

|

225

|

90

|

|

|||

|

MMRKS225160

|

225

|

160

|

|

|||

|

Double socket 90° Bend

|

|

|

|

|||

|

MMQKS63

|

63

|

|

|

|||

|

MMQKS75

|

75

|

|

|

|||

|

MMQKS90

|

90

|

|

|

|||

|

MMQKS110

|

110

|

|

|

|||

|

MMQKS125

|

125

|

|

|

|||

|

MMQKS140

|

140

|

|

|

|||

|

MMQKS160

|

160

|

|

|

|||

|

MMQKS200

|

200

|

|

|

|||

|

MMQKS225

|

225

|

|

|

|||

|

MMQKS250

|

250

|

|

|

|||

|

MMQKS315

|

315

|

|

|

|||

|

MMQKS400

|

400

|

|

|

|||

|

Double socket 45° Bend

|

|

|

|

|||

|

MMK45KS63

|

63

|

|

|

|||

|

MMK45KS75

|

75

|

|

|

|||

|

MMK45KS90

|

90

|

|

|

|||

|

MMK45KS110

|

110

|

|

|

|||

|

MMK45KS125

|

125

|

|

|

|||

|

MMK45KS140

|

140

|

|

|

|||

|

MMK45KS160

|

160

|

|

|

|||

|

MMK45KS200

|

200

|

|

|

|||

|

MMK45KS225

|

225

|

|

|

|||

|

MMK45KS250

|

250

|

|

|

|||

|

MMK45KS315

|

315

|

|

|

|||

|

MMK45KS400

|

400

|

|

|

|||

|

Double socket 22.5° Bend

|

|

|

|

|||

|

MMK22KS63

|

63

|

|

|

|||

|

MMK22KS75

|

75

|

|

|

|||

|

MMK22KS90

|

90

|

|

|

|||

|

MMK22KS110

|

110

|

|

|

|||

|

MMK22KS125

|

125

|

|

|

|||

|

MMK22KS140

|

140

|

|

|

|||

|

MMK22KS160

|

160

|

|

|

|||

|

MMK22KS200

|

200

|

|

|

|||

|

MMK22KS225

|

225

|

|

|

|||

|

MMK22KS250

|

250

|

|

|

|||

|

MMK22KS315

|

315

|

|

|

|||

|

MMK22KS400

|

400

|

|

|

|||

|

Double socket 11.25° Bend

|

|

|

|

|||

|

MMK11KS90

|

90

|

|

|

|||

|

MMK11KS110

|

110

|

|

|

|||

|

MMK11KS160

|

160

|

|

|

|||

|

MMK11KS225

|

225

|

|

|

|||

|

MMK11KS315

|

315

|

|

|

|||

|

All socket Tee

|

|

|

|

|||

|

MMBKS6363

|

63

|

63

|

|

|||

|

MMBKS7563

|

75

|

63

|

|

|||

|

MMBKS7575

|

75

|

75

|

|

|||

|

MMBKS9063

|

90

|

63

|

|

|||

|

MMBKS9075

|

90

|

75

|

|

|||

|

MMBKS9090

|

90

|

90

|

|

|||

|

MMBKS11063

|

110

|

63

|

|

|||

|

MMBKS11075

|

110

|

75

|

|

|||

|

MMBKS11090

|

110

|

90

|

|

|||

|

MMBKS110110

|

110

|

110

|

|

|||

|

MMBKS16090

|

160

|

90

|

|

|||

|

MMBKS160110

|

160

|

110

|

|

|||

|

MMBKS160160

|

160

|

160

|

|

|||

|

MMBKS22590

|

225

|

90

|

|

|||

|

MMBKS225110

|

225

|

110

|

|

|||

|

MMBKS225160

|

225

|

160

|

|

|||

|

MMBKS225225

|

225

|

225

|

|

|||

|

Double socket tee with loosing flanged branch

|

|

|

|

|||

|

MMAKSLS6365

|

63

|

|

65

|

|||

|

MMAKSLS7565

|

75

|

|

65

|

|||

|

MMAKSLS9040

|

90

|

|

40

|

|||

|

MMAKSLS9065

|

90

|

|

65

|

|||

|

MMAKSLS9080

|

90

|

|

80

|

|||

|

MMAKSLS11065

|

110

|

|

65

|

|||

|

MMAKSLS11080

|

110

|

|

80

|

|||

|

MMAKSLS110100

|

110

|

|

100

|

|||

|

MMAKSLS12565

|

125

|

|

65

|

|||

|

MMAKSLS12580

|

125

|

|

80

|

|||

|

MMAKSLS125100

|

125

|

|

100

|

|||

|

MMAKSLS14065

|

140

|

|

65

|

|||

|

MMAKSLS14080

|

140

|

|

80

|

|||

|

MMAKSLS140100

|

140

|

|

100

|

|||

|

MMAKSLS16065

|

160

|

|

65

|

|||

|

MMAKSLS16080

|

160

|

|

80

|

|||

|

MMAKSLS160100

|

160

|

|

100

|

|||

|

MMAKSLS160150

|

160

|

|

150

|

|||

|

MMAKSLS20060

|

200

|

|

60

|

|||

|

MMAKSLS20080

|

200

|

|

80

|

|||

|

MMAKSLS200100

|

200

|

|

100

|

|||

|

MMAKSLS200150

|

200

|

|

150

|

|||

|

MMAKSLS200200

|

200

|

|

200

|

|||

|

MMAKSLS22560

|

225

|

|

60

|

|||

|

MMAKSLS22580

|

225

|

|

80

|

|||

|

MMAKSLS225100

|

225

|

|

100

|

|||

|

MMAKSLS225150

|

225

|

|

150

|

|||

|

MMAKSLS225200

|

225

|

|

200

|

|||

|

MMAKSLS25060

|

250

|

|

60

|

|||

|

MMAKSLS25080

|

250

|

|

80

|

|||

|

MMAKSLS250100

|

250

|

|

100

|

|||

|

MMAKSLS250150

|

250

|

|

150

|

|||

|

MMAKSLS250200

|

250

|

|

200

|

|||

|

MMAKSLS250250

|

250

|

|

250

|

|||

|

MMAKSLS31560

|

315

|

|

60

|

|||

|

MMAKSLS31580

|

315

|

|

80

|

|||

|

MMAKSLS315100

|

315

|

|

100

|

|||

|

MMAKSLS315150

|

315

|

|

150

|

|||

|

MMAKSLS315200

|

315

|

|

200

|

|||

|

MMAKSLS315250

|

315

|

|

250

|

|||

|

MMAKSLS315300

|

315

|

|

300

|

|||

|

MMAKSLS40080

|

400

|

|

80

|

|||

|

MMAKSLS400100

|

400

|

|

100

|

|||

|

MMAKSLS400150

|

400

|

|

150

|

|||

|

MMAKSLS400200

|

400

|

|

200

|

|||

|

MMAKSLS400300

|

400

|

|

300

|

|||

|

MMAKSLS400400

|

400

|

|

400

|

|||

|

Double socket tee with flanged branch

|

|

|

|

|||

|

MMAKS9080

|

90

|

|

80

|

|||

|

MMAKS11080

|

110

|

|

80

|

|||

|

MMAKS110100

|

110

|

|

100

|

|||

|

MMAKS16080

|

160

|

|

80

|

|||

|

MMAKS160100

|

160

|

|

100

|

|||

|

MMAKS160150

|

160

|

|

150

|

|||

|

MMAKS22580

|

225

|

|

80

|

|||

|

MMAKS225100

|

225

|

|

100

|

|||

|

MMAKS225150

|

225

|

|

150

|

|||

|

MMAKS225200

|

225

|

|

200

|

|||

|

Socket Cap

|

|

|

|

|||

|

CKS90

|

90

|

|

|

|||

|

CKS225

|

225

|

|

|

|||

|

Flanged Spigot For PVC Pipe

|

|

|

|

|||

|

FKS90

|

90

|

|

80

|

|||

|

FKS225

|

225

|

|

200

|

|||

|

FKS315

|

315

|

|

300

|

|||

|

Rubber Gaskets

|

|

|

|

|||

|

RG63

|

63

|

|

|

|||

|

RG75

|

75

|

|

|

|||

|

RG90

|

90

|

|

|

|||

|

RG110

|

110

|

|

|

|||

|

RG160

|

160

|

|

|

|||

|

RG200

|

200

|

|

|

|||

|

RG225

|

225

|

|

|

|||

|

RG250

|

250

|

|

|

|||

|

RG315

|

315

|

|

|

|||

|

RG400

|

400

|

|

|

|||

* Most reasonable

* Most light

* Most competitive

* Quality & Efficiency improved

Ductile iron pipe fitting and PVC plastic pipe fitting performance comparison:

Compared with ductile iron pipe fitting, PVC pipe fitting is characterized by smooth inner wall, light weight, corrosion

resistance, anti scaling performance, low price, but also more shortcomings, mainly have the following points:

(1) Easy to aging, thermal expansion and cold contraction, should not be exposed to sunlight for a long time, stored at room temperature should not be greater than 40℃.

(2) Low strength, poor compressive performance, improper construction is easy to cause deformation.

(3) Poor rigidity, poor deflection, easy to cause leakage.

Ductile iron pipe fitting are vastly superior to grey cast iron pipe fitting and silicon pressure pipes in the tensile, bending,

hardness, elongation, resistance to impact and hydrostatic test technical performance, and the corrosion resistance and service life and is superior to the steel pipe fitting. Considering the mechanical properties, tensile, compressive strength of ductile iron pipe fitting is more than double of grey cast pipe fitting, much higher than steel pipe fitting. Because the ductile iron pipe fitting adopts Push in flexible joint, it has good sealing and flexibility, and the pipe fitting itself has a larger

elongation, so that the pipe fitting has good flexibility, so that a small amount of uneven settlement can be accepted in the

buried pipeline, improving the stress state of the pipeline and the surrounding soil. In addition, the expansion caused by water temperature changes in the pipeline can also be absorbed in the joint, will not lead to joint leakage.

Compared with ductile iron pipe fitting, PVC pipe fitting is characterized by smooth inner wall, light weight, corrosion

resistance, anti scaling performance, low price, but also more shortcomings, mainly have the following points:

(1) Easy to aging, thermal expansion and cold contraction, should not be exposed to sunlight for a long time, stored at room temperature should not be greater than 40℃.

(2) Low strength, poor compressive performance, improper construction is easy to cause deformation.

(3) Poor rigidity, poor deflection, easy to cause leakage.

Ductile iron pipe fitting are vastly superior to grey cast iron pipe fitting and silicon pressure pipes in the tensile, bending,

hardness, elongation, resistance to impact and hydrostatic test technical performance, and the corrosion resistance and service life and is superior to the steel pipe fitting. Considering the mechanical properties, tensile, compressive strength of ductile iron pipe fitting is more than double of grey cast pipe fitting, much higher than steel pipe fitting. Because the ductile iron pipe fitting adopts Push in flexible joint, it has good sealing and flexibility, and the pipe fitting itself has a larger

elongation, so that the pipe fitting has good flexibility, so that a small amount of uneven settlement can be accepted in the

buried pipeline, improving the stress state of the pipeline and the surrounding soil. In addition, the expansion caused by water temperature changes in the pipeline can also be absorbed in the joint, will not lead to joint leakage.

Quality Control

SYI Pipeline regards quality as an essential and integral part of our business success.

Until now, we are ISO9001:2015 TUV, BSI Kitemarked, SGS, BV, FM certified, and UL, WRAS listed. We are the approved supplier to many worldwide known countries and authorities.

Manufacturing "SYI" Brand products has evolved as a mark of quality!

Packing & Delivery

Packing:

Different package upon your request,like wood cases&pallets,ply-wood crates&pallets,steel crates&pallets and etc.

Hot Searches