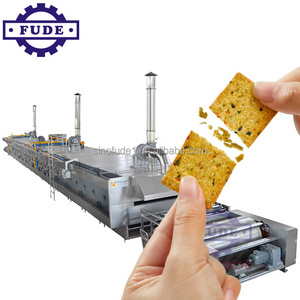

Tunnel ovens use different heating methods, conveyor speeds and fuel types to produce breads, biscuits, and other items.

A wide range of models working with different heating systems.

Their equipment and dimensions can be adapted according to the production needs.

Our technical department is at complete disposal for any kind of information aimed at the supply of a first rate plant granting

performances and reliability.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

65-830kw

-

Dimension(L*W*H):

-

L29-125m

-

Weight:

-

45000 KG

-

Machinery Function:

-

biscuit making machine, biscuit line, Cookies making machine, Cracker production line, Sandwich biscuit making machine

-

Output product name:

-

Biscuit Cookies Cracker

-

Function:

-

Multifunctional

-

Product name:

-

Biscuit Production Line

-

Material:

-

304 Stainess Steel

-

Keywords:

-

Industrial Biscuit Snack Machine

-

Automatic:

-

Touch Screen Control

-

Power Source:

-

Electric/Gas

-

Capacity:

-

100-1250kg/hr

-

Biscuit Type:

-

Soft Hard Soda Sandwich Biscuit

-

Conveyor Belt:

-

carbon steel

Quick Details

-

Marketing Type:

-

Hot Product 2020

-

Brand Name:

-

Junyu Food Machinery

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

380V

-

Power:

-

65-830kw

-

Dimension(L*W*H):

-

L29-125m

-

Weight:

-

45000 KG

-

Machinery Function:

-

biscuit making machine, biscuit line, Cookies making machine, Cracker production line, Sandwich biscuit making machine

-

Output product name:

-

Biscuit Cookies Cracker

-

Function:

-

Multifunctional

-

Product name:

-

Biscuit Production Line

-

Material:

-

304 Stainess Steel

-

Keywords:

-

Industrial Biscuit Snack Machine

-

Automatic:

-

Touch Screen Control

-

Power Source:

-

Electric/Gas

-

Capacity:

-

100-1250kg/hr

-

Biscuit Type:

-

Soft Hard Soda Sandwich Biscuit

-

Conveyor Belt:

-

carbon steel

Production Description

Automatic biscuit production line

Commercial biscuit-making machines make biscuits of different shapes, sizes, and varieties round biscuits, oval biscuits, hollow round biscuits, square biscuits, etc. They can be used for small-scale production or large-scale production as well.

The advantages of using Junyu biscuit-making machines are:

♦ 1. CE ISO certificate stander production

♦ 2. Low price and good quality with SEW/ABB/Siemens Brand

♦ 3. Industrial design, easy to operate and maintain and oversea service

♦ 4. Large production capacity, high efficiency, and low power require and cost

♦ 5. Real factory give turn-key solution, oversea training ,foumlar help

♦ 1. CE ISO certificate stander production

♦ 2. Low price and good quality with SEW/ABB/Siemens Brand

♦ 3. Industrial design, easy to operate and maintain and oversea service

♦ 4. Large production capacity, high efficiency, and low power require and cost

♦ 5. Real factory give turn-key solution, oversea training ,foumlar help

|

Model

|

JYB-600

|

JYB-800

|

JYB-1000

|

JYB-1200

|

JYB-1500

|

|

Production capacity(kg/h)

|

500

|

750

|

1000

|

1200

|

1500

|

|

Total length(mm)

|

85500

|

92500

|

125000

|

150000

|

170000

|

|

Baking temp(℃)

|

190-240

|

190-240

|

190-240

|

190-240

|

190-240

|

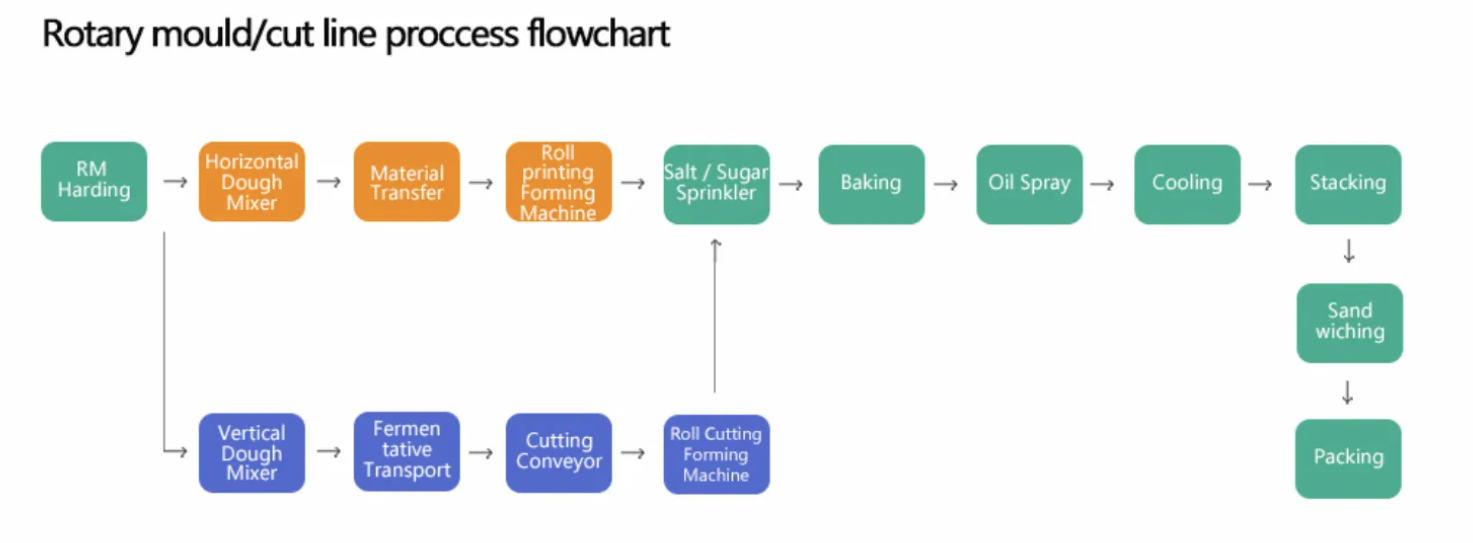

Part 1.

Raw Material Processing system

Junyu can offer a fully automatic processing unit from flour to mixer with

Oil /Fat processing system, Sugar powder grading, and filter system, Flour filter & winnowing transfer system,Industrial Dough mixer,Dough Feeding Conveyor Belt

Horizontal Mixer

The horizontal mixer is a base mixer for industrial mixing, which can be used on the soft and hard dough, especially for soft or cookie dough.

Vertical Mixer

Vertical mixer and spindle mixer are the most popular mixer for mixing cracker dough, especially for the need for second fermentation dough.

Part 2.Soft biscuit-Rotary molder system

The Soft Biscuit is commonly known as shortbread biscuit obtained, that is, from the tender dough (fragile, not hard); they are obtained using a rotary machine, therefore shortbread biscuits are also technically known as rotary biscuits.

Soft biscuits will have fewer processing machines than Cracker/Hard biscuit form mixer can directly to the forming no need extra dough process unit.

Soft biscuits will have fewer processing machines than Cracker/Hard biscuit form mixer can directly to the forming no need extra dough process unit.

Part3.Cracker biscuit-Rotary cutter system

They are fairly crunchy biscuits, just hard on the first bite and then crumbly on the palate, leaving the typical vanilla flavor in the mouth. Within the family of dry biscuits we find the typical French “Marie” and the “Petit Beurre” , the English “Oswego”,“gem biscuits” and “cabin”, but also the families of “cream crackers”, the “soda crackers “,” snack crackers“ and ”water crackers“.

The main ingredient of this family of products is flour and its types since the dry product is mainly composed of flour and water, with a modest amount of sugar and fat.

The Rotary cutter machine is usually used on forming Hard/Cracker biscuits form the Laminator to rotary cutter is for making hard biscuits.

Cracker biscuit forming process like below:

Part4. Baking oven

JUNYU designs and manufactures tunnel oven for industrial production.

CONVECTION TUNNEL OVEN

DIRECT GAS TUNNEL OVEN

CYCLOTHYMIC TUNNEL OVEN

Junyu Packing system

We have different packing systems such as Pillow shapes, Biscuit with tray packing, Sandwiching packing etc...

Part 5. Oiling & Packing

After baking, if the customer wants to add a better smell and shining dark color to the biscuit then the Oil sprayer system is a must before the biscuit cools and packed.

Junyu oil sprayer is dish type to reach the mist type to save the waste of the oil.

Products this line can produce

FAQ

Q1: Whats the different between Junyu & others?

JUNYU OTHERS

Q2:

I have no experience about this industry What kind of service can you provide?

A:

We provide turn-key service,including raw-materials, recipe, training, install and Shipping.

Q3:

What about your After sale guarantee?

A:

We can provide Half year over sea training and three years guarantees. We also provide annual machine maintenance at customer's local country.

Q4: What‘s the different between Junyu and other factories?

A:Junyu

company was founded in

1989

and registered in

2008

with a registered capital of 50 million RMB yuan. The factory covers an area of

8000 square meters

and the office covers an area of 300 square meters.

We have our own Processing workshop with 3CNC machines etc...can control our quality form the raw material and cost

Customer Introduce

Junyu cooperated

Top3 customer

1. Oreo

Technology Support ★★★★★ Great Turnkey Service ★★★★★

12 drawing designer and 20 professional engineers,which can offer your support anytime and anywhere. Can be video call online to guide you how the machine install and maintain.

We can provide you with the turnkey solution ,to help you solve all process from plan to install,and then shipping all equipment to your factory.Help you install and train workers.

High Quality Machines

★★★★★

Full Formula Support

★★★★★

All machines made in the GMP standard factory. We have the CNC center to keep the machine precious. All machine use SUS304 and sandblasting surface coating handling.

We have cooperated with the authoritative scientific research institute. to custom, the special formula for you with your machine, ensure you make the best gummy with a good deal.

Certifications

Hot Searches