- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

3 phase 380V, 50Hz

-

Power:

-

6KW

-

Dimension(L*W*H):

-

2100x1200x1800 mm

-

Weight:

-

2100 kg

-

Finished Products:

-

Paper Cup Paper Bowl

-

Name:

-

Disposable Paper Cup Making Machine

-

Raw material:

-

PE Coated Paper

-

Application:

-

Paper Cup Industry

-

Type:

-

Paper Cup Producton Line

-

Speed:

-

80-90PCS/MIN

-

Suitable paper weight:

-

140~350gsm

-

Paper Cup Size:

-

2 ~12 OZ (50ml~330ml Mould Exchangeable)

-

Cup Side Welding:

-

Ultrasonic Heater

-

Cup Bottom Heating:

-

Hot Air system

Quick Details

-

Production Capacity:

-

75-85 pcs/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yugong/ OEM

-

Voltage:

-

3 phase 380V, 50Hz

-

Power:

-

6KW

-

Dimension(L*W*H):

-

2100x1200x1800 mm

-

Weight:

-

2100 kg

-

Finished Products:

-

Paper Cup Paper Bowl

-

Name:

-

Disposable Paper Cup Making Machine

-

Raw material:

-

PE Coated Paper

-

Application:

-

Paper Cup Industry

-

Type:

-

Paper Cup Producton Line

-

Speed:

-

80-90PCS/MIN

-

Suitable paper weight:

-

140~350gsm

-

Paper Cup Size:

-

2 ~12 OZ (50ml~330ml Mould Exchangeable)

-

Cup Side Welding:

-

Ultrasonic Heater

-

Cup Bottom Heating:

-

Hot Air system

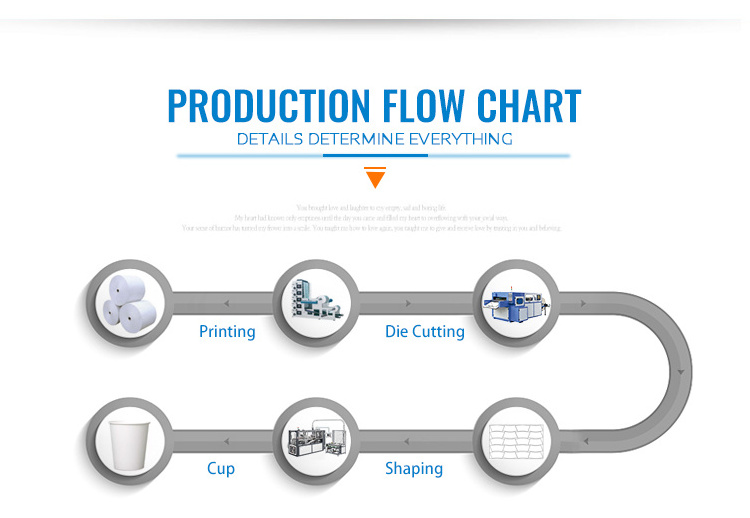

Product Description

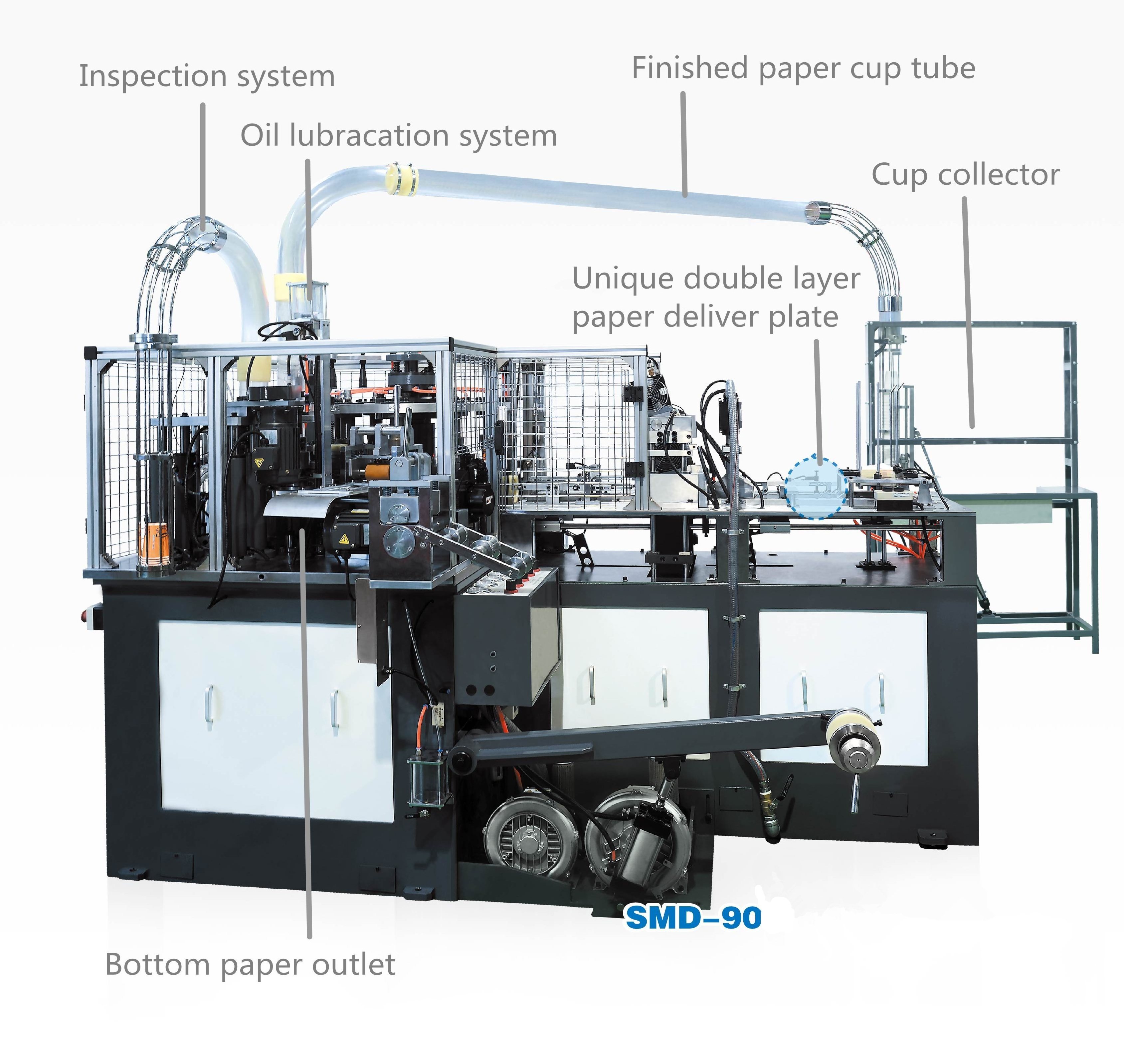

Reliability:

Smart middle speed paper cup forming machine is provided with advantages of high performance,high efficiency and high quality. The overall steel plate machine body and oil-spraying lubrication system ensures normal and stable long-term operation of the equipment.

High Efficiency and Energy Conservation:

Advanced high-precision cylindrical cam driving unit working with gear drive system make sure the precisely working of every station. Bottom paper feeding controlled by servo tracking system,and raw material paper can be saved effectively.

International Technical:

Paper bottom heating system(Switzerland Leister)uses 2 steps flameless heating.

Every step in production is monitored by photocell (Japan Omron)and be reported.

User-friendly Design:

The function of machine is controlled by human-computer interface and PLC system. Manual operation can be replaced by automatic paper cup counting and collection table with appropriate setting.

Advanced high-precision cylindrical cam driving unit working with gear drive system make sure the precisely working of every station. Bottom paper feeding controlled by servo tracking system,and raw material paper can be saved effectively.

International Technical:

Paper bottom heating system(Switzerland Leister)uses 2 steps flameless heating.

Every step in production is monitored by photocell (Japan Omron)and be reported.

User-friendly Design:

The function of machine is controlled by human-computer interface and PLC system. Manual operation can be replaced by automatic paper cup counting and collection table with appropriate setting.

Specification

|

Cup size

|

3~16oz (outside diameter of cup 60-90 mm, outside diameter of bottom

50~70 mm, height of cup 50~135 mm, depth of bottom 5~10 mm)

|

|

Rated speed

|

90-110pcs/min

|

|

Main motor power

|

2.2KW

|

|

Electro thermal power

|

8.6/13.2KW

|

|

Air source

|

0.6m/min; 0.6MPa customer-owned

|

|

Applical base paper

|

190~350g/(single or double PE coating paper)

|

|

Weight

|

3800 kg

|

|

Main size

|

2700*1500*1800 mm

|

|

Paper cup collector size

|

1150*850*2000 mm

|

|

Actual power consumption

|

7.5KW

|

|

Remark

|

The paper thickness error margin is ±0.05mm for the same set of mould

|

Adopt Open Cam for the dividing moving, compare with index gearbox,easy maintenance, stable and reliable, easy replace broken parts.

Packing & Delivery

Our Services

1.We have more than15 years manufacture and export experience.

2.Exporting to all over the world,win high reputation among customers.

3.CE, ISO 9001 and Strict Production Guideline to guarantee the high quality of our products.

4.Near the Qingdao port convenient for exporting.

5.Customer service staff 24 hours online,offer free technical support.

6.Factory and Competitive Price we offer.

7.Strong Research & Development technical team.

8.Various machinery to meet all your needs at our factory.

9.Engineers are available to guide the installation and take care of other problems.

10.We offer OEM&ODM service to meet all your requirements.

2.Exporting to all over the world,win high reputation among customers.

3.CE, ISO 9001 and Strict Production Guideline to guarantee the high quality of our products.

4.Near the Qingdao port convenient for exporting.

5.Customer service staff 24 hours online,offer free technical support.

6.Factory and Competitive Price we offer.

7.Strong Research & Development technical team.

8.Various machinery to meet all your needs at our factory.

9.Engineers are available to guide the installation and take care of other problems.

10.We offer OEM&ODM service to meet all your requirements.

FAQ

Q1. What size of the cup/bowl you can make?

We can make paper cups/bowls from 2.5OZ-45OZ.

Q2. What is the packing way of the machine?

Usual , With wooden cases packing or iron tray packing.

Q3. How about the machine guarantee?

One year. During this period, any parts damaged caused by machine self, the seller will repair/replace the spare parts for free.

After one year, the seller will supply the spare parts to buyers as the cost. The machine service is all around the machine life.

Q4. What about the machine installation and training?

If customer request, we will send our technician to install and train operation, but all costs should be covered by buyer. (including getting visa, 2-way air tickets, food. Hotel. Local traffic, translator, salary ).

Q5.What about the payment term?

Mostly 30%T/T in advanced,the rest need paid before shipping, or L/C at sight.

Q6.What information should i let you know if i want to get a quotation?

--Quantity

--What's the detailed size (top diameter,bottom diameter,and height)

--What's the paper thickness.

We can make paper cups/bowls from 2.5OZ-45OZ.

Q2. What is the packing way of the machine?

Usual , With wooden cases packing or iron tray packing.

Q3. How about the machine guarantee?

One year. During this period, any parts damaged caused by machine self, the seller will repair/replace the spare parts for free.

After one year, the seller will supply the spare parts to buyers as the cost. The machine service is all around the machine life.

Q4. What about the machine installation and training?

If customer request, we will send our technician to install and train operation, but all costs should be covered by buyer. (including getting visa, 2-way air tickets, food. Hotel. Local traffic, translator, salary ).

Q5.What about the payment term?

Mostly 30%T/T in advanced,the rest need paid before shipping, or L/C at sight.

Q6.What information should i let you know if i want to get a quotation?

--Quantity

--What's the detailed size (top diameter,bottom diameter,and height)

--What's the paper thickness.

Hot Searches