- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

280/380

-

Dimension(L*W*H):

-

Different models

-

Weight:

-

2750 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Ore

-

Color:

-

Customers' Request

-

Capacity:

-

10-20000t/h

-

Application area:

-

Tin Ore

-

Installation:

-

Engineer Guide

-

Certification:

-

ISO:9001

Quick Details

-

Production Capacity:

-

98%

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GUOTE

-

Voltage:

-

280/380

-

Dimension(L*W*H):

-

Different models

-

Weight:

-

2750 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Ore

-

Color:

-

Customers' Request

-

Capacity:

-

10-20000t/h

-

Application area:

-

Tin Ore

-

Installation:

-

Engineer Guide

-

Certification:

-

ISO:9001

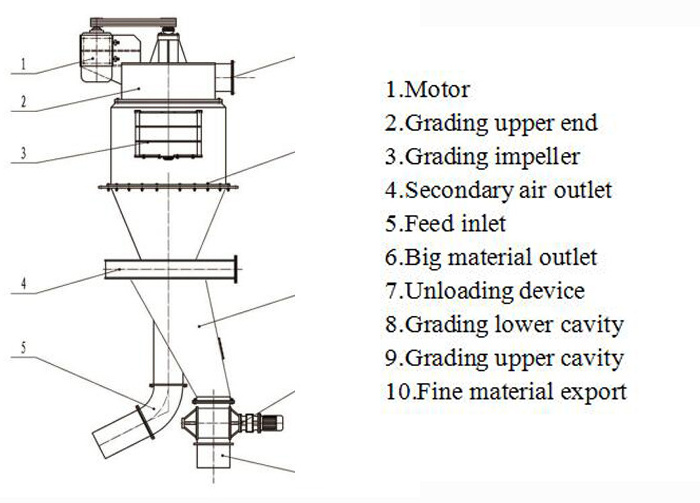

china manufacturer powder air classifier mill pulverizer with cyclone for ceramic

1.With special design for classifying structure and its high classifying precision, it can block big granular strictly.

2.To get the required product, you can adjust the rotary speed of classifying wheel and air inlet volume.

3.Single vertical rotor with low speed, steady flow field, high efficiency and robust performance.

4.With multi-series structure, it can get products with different size to meet requirement

Technical parameter:

| Model | Capacity(kg/h) | Efficiency | of classification Product Particle Size(um) | Power(kw) |

| GF010 | 10-50 | 70-90% | D97=3-50 | 7 |

| GF020 | 50-350 | 15-19 | ||

| GF050 | 100-800 | 25-30 | ||

| GF100 | 300-1500 | 41-48 | ||

| GF200 | 500-4000 | 63-73 | ||

| GF400 | 2000-5000 | 97-20 | ||

| GF500 | 3000-6000 | 110-30 | ||

| GF600 | 4000-8000 | 140-169 | ||

| GF800 | 6000-12000 | 170-210 | ||

| GF1200 | 8000-20000 | 70-90% | D97=3-50 | 230-280 |