- Product Details

- {{item.text}}

Quick Details

-

voltage:

-

220VAC 50/60Hz, single phase

-

power:

-

2000w

-

source power:

-

Two sputtering power

-

vacuum chamber size:

-

300 mm Dia x 300 mm height

-

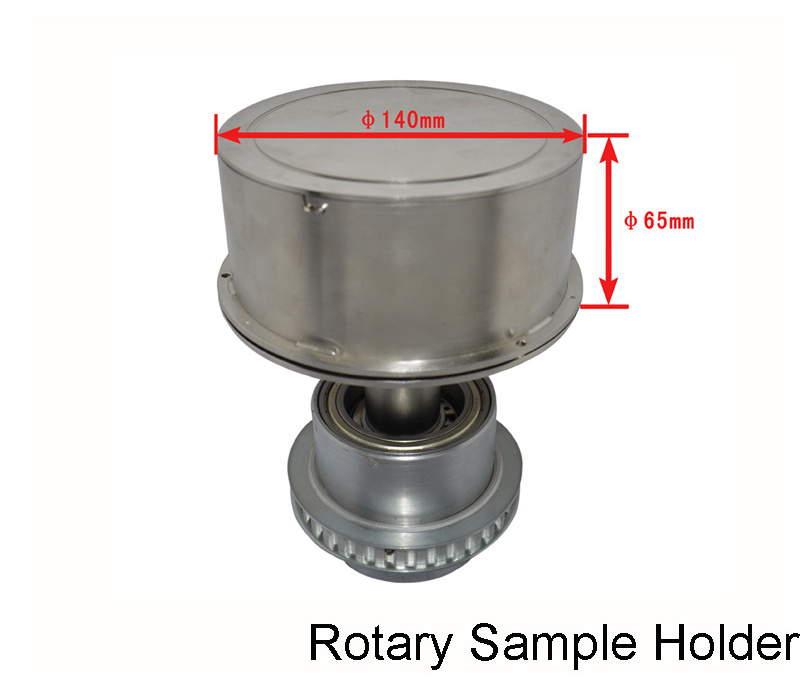

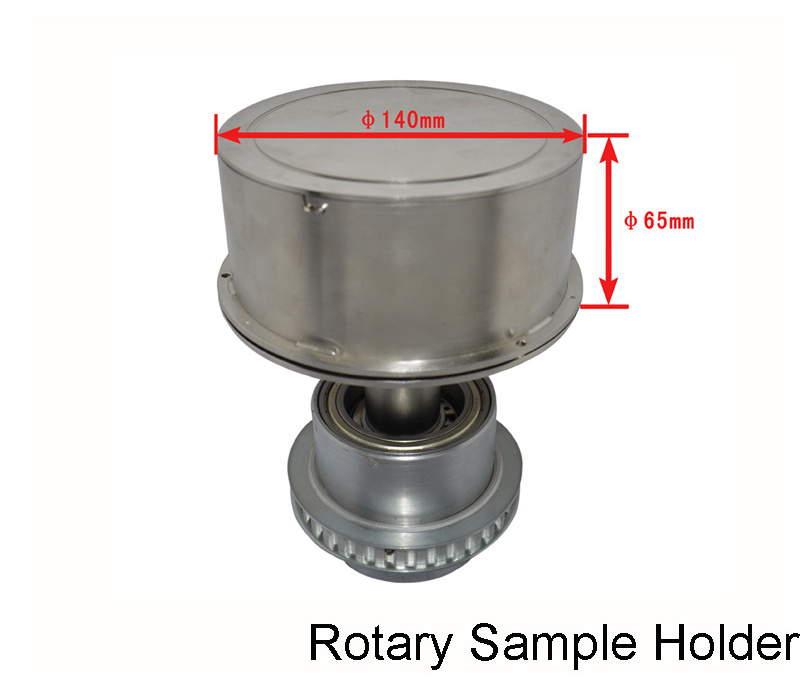

Sample holder size:

-

140mm dia. for. 4" wafer max

-

Sample holder rotation speed:

-

1 - 20 rpm for uniform coating adjustable

-

Flow rate.:

-

200 ml/min max

-

Keywords:

-

Magnetron Sputter Source

-

Weight:

-

160KG

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Henan, China

-

After-sales Service Provided:

-

Online support, Engineers available to service machinery overseas

-

Product:

-

Magnetron Plasma Sputtering Coater system

-

voltage:

-

220VAC 50/60Hz, single phase

-

power:

-

2000w

-

source power:

-

Two sputtering power

-

vacuum chamber size:

-

300 mm Dia x 300 mm height

-

Sample holder size:

-

140mm dia. for. 4" wafer max

-

Sample holder rotation speed:

-

1 - 20 rpm for uniform coating adjustable

-

Flow rate.:

-

200 ml/min max

-

Keywords:

-

Magnetron Sputter Source

-

Weight:

-

160KG

-

Certification:

-

CE

Dual-Head Magnetron Plasma Sputtering system with 2" High Vacuum Magnetron Sputter Source for Semiconductor film

Brief introduction of the magnetron sputtering system:

VTC-600-2HD is a compact magnetron sputtering system with dual 2" target sources, e.g., one DC source for coating metallic film, and another RF source for coating non-metallic material. A film thickness tracker is included to enable the user to control processing easily. This coater is designed for coating both single or multiple film layers for a wide range of materials, such as alloy, ferroelectric, semiconductor, ceramic, dielectric, optical, PTFE etc. at low cost.

Specification of the DC/RF Dual-Head High Vacuum 2" Magnetron Plasma Sputtering Coater system

| Compact Structure |

|

| Input Power |

|

| Source Power |

Two sputtering power sources are integrated into one control box

|

| Magnetron Sputtering Head |

|

| Vacuum Chamber |

|

| Sample Holder |

|

| Gas Flow Control |

|

| Vacuum Pump Station |

|

| Thickness Monitor |

|

| Overall Dimensions | L1300mm× W660mm× H1200mm |

| Net Weight | 160 kg |

| Warranty | One years limited warranty with lifetime support |

| Application Note |

|

Display of the DC/RF Dual-Head High Vacuum 2" Magnetron Plasma Sputtering Coater system

Founded in 2005, Zhengzhou CY Scientific Instrument Co., Ltd. is a company specializing in the development and production of laboratory technology research equipment. The products are mixed, pressed, burned, cut, ground, polished, coated, analytical equipment and related consumables. Products include laboratory sintering equipment, coating equipment and so on. At present, it has been exported to 25 countries and regions such as the United States, Europe, and Southeast Asia, and has been well received by various scientific research units.

We have a mature technology research and development team, the number of technicians is 33, the company has 150 people, more than 500 square meters of office space, the factory covers an area of about 1,500 square meters located in Zhengzhou High-tech Zone Electronic Industrial Park. The products are mainly located in the research market, serving scientific research in the labs of universities and colleges, and can also customize products according to your needs.

Q. Are you a manufacturer or a trading company?

A. We are professional laboratory instrument manufacturers, have their own design team and factory, have mature technical experience, and can guarantee the quality of products and the optimal price.

Q. How is your company's product after-sales service system?

A. The product warranty period is 12 months, we can provide lifetime maintenance. We have professional pre-sales and after-sales departments that can respond to you within 24 hours to resolve any technical issues.

Q. How long is your delivery time? If I want to customize the instrument, how long does it take?

A. 1. If the goods are in stock, it is 5-10 days. 2. We can provide customized services for our customers. It usually takes 30-60 days depending on the specifications of the custom instrument.

Q. Our country's power supply and plug are different. How do you solve it?

A. We can supply a transformer and plug according to your local requirements according to the power plug of different countries.

Q. How to pay?

A. T / T, L / C, D / P, etc., it is recommended to use Alibaba Trade Guarantee.

Q. How is the package of goods? Delivery methods?

A. 1. Standard export fumigation sign wooden box packaging 2. Express, air, sea shipping according to customer requirements, find the most suitable way.

More questions, please contact customer service