- Product Details

- {{item.text}}

Quick Details

-

Mold Height(mm):

-

75 - 135 mm

-

Ejector Stroke(mm):

-

80 mm

-

Ejector Force(kN):

-

5 kN

-

Theoretical Shot Volume(cm³):

-

20 cm³

-

Injection Rate (g/s):

-

80 g/s

-

Injection Weight (g):

-

80 g

-

Screw Speed (rpm):

-

10 - 200 rpm

-

Screw diameter (mm):

-

16 mm

-

Screw L/D Ratio:

-

19.8

-

Distance between Tie Bars:

-

200x130 mm

-

Weight (KG):

-

50 kg

-

Place of Origin:

-

Jiangsu, China

-

Open Stroke(mm):

-

50 mm

-

Model Number:

-

10

-

Brand Name:

-

Ipretech

-

Power (kW):

-

0.5 kW

-

Marketing Type:

-

New Product 2022

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

150mm

-

Distance between Tie Bars(Height)(mm):

-

180mm

-

Plasticizing Capacity(g/s):

-

20

-

Mold Height(mm):

-

75 - 135 mm

-

Ejector Stroke(mm):

-

80 mm

-

Ejector Force(kN):

-

5 kN

-

Theoretical Shot Volume(cm³):

-

20 cm³

-

Injection Rate (g/s):

-

80 g/s

-

Injection Weight (g):

-

80 g

-

Screw Speed (rpm):

-

10 - 200 rpm

-

Screw diameter (mm):

-

16 mm

-

Screw L/D Ratio:

-

19.8

-

Distance between Tie Bars:

-

200x130 mm

-

Weight (KG):

-

50 kg

-

Place of Origin:

-

Jiangsu, China

-

Open Stroke(mm):

-

50 mm

-

Model Number:

-

10

-

Brand Name:

-

Ipretech

-

Power (kW):

-

0.5 kW

-

Marketing Type:

-

New Product 2022

Product Description

Specification

|

item

|

value

|

|

Plastic Processed

|

PP, PC, ABS, PET, PVC, PE, PE/PP

|

|

Condition

|

New

|

|

Style

|

Horizontal

|

|

|

150mm

|

|

|

180mm

|

|

Plasticizing Capacity(g/s)

|

20

|

|

Mold Height(mm)

|

75mm - 135mm

|

|

Ejector Number

|

1

|

|

Ejector Stroke(mm)

|

80mm

|

|

Ejector Force(kN)

|

5kN

|

|

Theoretical Shot Volume(cm³)

|

20cm³

|

|

Injection Rate (g/s)

|

80g/s

|

|

Machine Type

|

Hydraulic

|

|

Injection Weight (g)

|

80g

|

|

Screw Speed (rpm)

|

10rpm - 200rpm

|

|

Screw diameter (mm)

|

16mm

|

|

Screw L/D Ratio

|

19.8

|

|

Distance between Tie Bars

|

200x130 mm

|

|

Weight (KG)

|

50kg

|

|

Type

|

Preform Injection

|

|

Place of Origin

|

China

|

|

|

Jiangsu

|

|

Open Stroke(mm)

|

50mm

|

|

Model Number

|

10

|

|

Brand Name

|

Ipretech

|

|

Power (kW)

|

0.5kW

|

|

Warranty

|

1 Year

|

|

Key Selling Points

|

Automatic

|

|

Applicable Industries

|

Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Home Use, Advertising Company

|

|

Showroom Location

|

Egypt, Canada, United Kingdom, United States, France, Germany, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Mexico, Russia, Spain, South Korea, Algeria, Sri Lanka, Bangladesh, South Africa, Nigeria, Tajikistan, Japan

|

|

Marketing Type

|

New Product 2021

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

Motor, PLC, Other

|

1. Equipment introduction

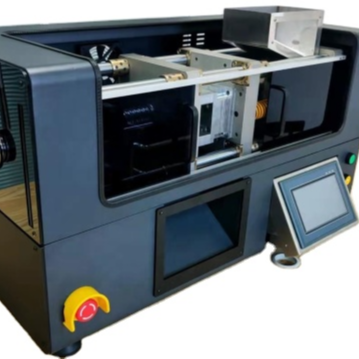

Desktop Ject is a desktop injection molding machine designed to meet the needs of makers, CNC education, and low-cost design and manufacturing.

The whole machine can be placed on any desktop for operation and use, and the process from design to finished product can be quickly completed with low operating costs.

Support multiple types of plastic injection molding, PP, PE, ABS, POM, PA PLA, TPU, PMMA.

Suitable for the production of precision injection molded parts: electronic instruments, auto parts, medical accessories, daily necessities, laboratories, etc.

2. Product Features

2.1 Compact structure, small footprint. Standardized industrial design, simple operation and convenient use

2.2 High precision and long life. Highly optimized mechanical mechanism, high-performance controller

2.3 Intelligent control, color touch screen, simple UI, injection pressure curve display, multi-language settings, friendly

operation

2.4 Double servo motors, fast response, higher efficiency and low energy consumption

2.5 Stable performance. High precision (±0.5℃) Four-stage PID constant temperature control, three-stage barrel, one-stage mold temperature, precise temperature control.

2.6 Security. Anti-cold start protection, low torque mold clamping protection, protective door design

2.7 Alloy barrel (nitriding alloy material + quenching and tempering heat treatment), anti-overflow plastic injection head

Desktop Ject is a desktop injection molding machine designed to meet the needs of makers, CNC education, and low-cost design and manufacturing.

The whole machine can be placed on any desktop for operation and use, and the process from design to finished product can be quickly completed with low operating costs.

Support multiple types of plastic injection molding, PP, PE, ABS, POM, PA PLA, TPU, PMMA.

Suitable for the production of precision injection molded parts: electronic instruments, auto parts, medical accessories, daily necessities, laboratories, etc.

2. Product Features

2.1 Compact structure, small footprint. Standardized industrial design, simple operation and convenient use

2.2 High precision and long life. Highly optimized mechanical mechanism, high-performance controller

2.3 Intelligent control, color touch screen, simple UI, injection pressure curve display, multi-language settings, friendly

operation

2.4 Double servo motors, fast response, higher efficiency and low energy consumption

2.5 Stable performance. High precision (±0.5℃) Four-stage PID constant temperature control, three-stage barrel, one-stage mold temperature, precise temperature control.

2.6 Security. Anti-cold start protection, low torque mold clamping protection, protective door design

2.7 Alloy barrel (nitriding alloy material + quenching and tempering heat treatment), anti-overflow plastic injection head

Machine Details

|

Equipment size

|

850*430*500 mm

|

equipment power

|

2KW

|

|

Motor

|

Servo motor

|

Clamping force

|

5T

|

|

Screw size

|

16mm

|

power supply

|

220V/110V

|

|

touch screen

|

7 inch

|

Maximum injection volume

|

20g

|

|

Maximum mold size

|

200*130mm

|

Minimum mold thickness

|

75mm

|

|

Maximum mold thickness

|

135mm

|

Glue injection method

|

High-speed extrusion

|

|

Maximum injection capacity

|

600kg(60Mpa)

|

Maximum injection speed

|

80mm/s

|

|

Maximum heating temperature

|

80mm/s

|

Maximum heating temperature

|

300℃

|

|

Maximum ejection stroke

|

80mm

|

Heating section

|

4 sections (3 sections of material temperature + 1 section of mold temperature)

|

|

Heating accuracy

|

±0.5℃

|

Adaptation material

|

PP PE ABS

|

FAQ

1. who are we?

We are based in Jiangsu, China, start from 2016,sell to Domestic Market(40.00%),North America(20.00%),Western Europe(10.00%),Southeast Asia(10.00%),Eastern Europe(10.00%),South America(5.00%),Southern Europe(5.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

EDM WIRE CUT,EDM Small hole dirll,EDM Erosion die sinking,CNC Milling Machine,injection molding machine ,Metal engraving machine

4. why should you buy from us not from other suppliers?

Ipretech machinery company limited is an integrated research & development, manufacturing, import & export as one of the professional CNC machinery tool enterprises. Mainly engaged in a full ranges production of all kinds of edm wirecut, drill, die sinking

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,Western Union,Cash;

Language Spoken:English,Chinese,Spanish,Russian

We are based in Jiangsu, China, start from 2016,sell to Domestic Market(40.00%),North America(20.00%),Western Europe(10.00%),Southeast Asia(10.00%),Eastern Europe(10.00%),South America(5.00%),Southern Europe(5.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

EDM WIRE CUT,EDM Small hole dirll,EDM Erosion die sinking,CNC Milling Machine,injection molding machine ,Metal engraving machine

4. why should you buy from us not from other suppliers?

Ipretech machinery company limited is an integrated research & development, manufacturing, import & export as one of the professional CNC machinery tool enterprises. Mainly engaged in a full ranges production of all kinds of edm wirecut, drill, die sinking

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,Western Union,Cash;

Language Spoken:English,Chinese,Spanish,Russian

Hot Searches