- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1.1*2.45*1.25

-

Weight:

-

300 kg

-

Name:

-

feed mixer and grinder

-

Function:

-

Aniaml Feed Puffed Pellet Machine

-

Capacity:

-

100---3500kg/h

-

Motor:

-

China Brand

-

Material:

-

Durable Carbon Steel

-

Color:

-

Blue

-

Feed types:

-

Livestock Pellet Feed

-

Usage:

-

Animal Feed Processing Chaff Cutter Machine

Quick Details

-

Max. Capacity:

-

3 ton/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ssd

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1.1*2.45*1.25

-

Weight:

-

300 kg

-

Name:

-

feed mixer and grinder

-

Function:

-

Aniaml Feed Puffed Pellet Machine

-

Capacity:

-

100---3500kg/h

-

Motor:

-

China Brand

-

Material:

-

Durable Carbon Steel

-

Color:

-

Blue

-

Feed types:

-

Livestock Pellet Feed

-

Usage:

-

Animal Feed Processing Chaff Cutter Machine

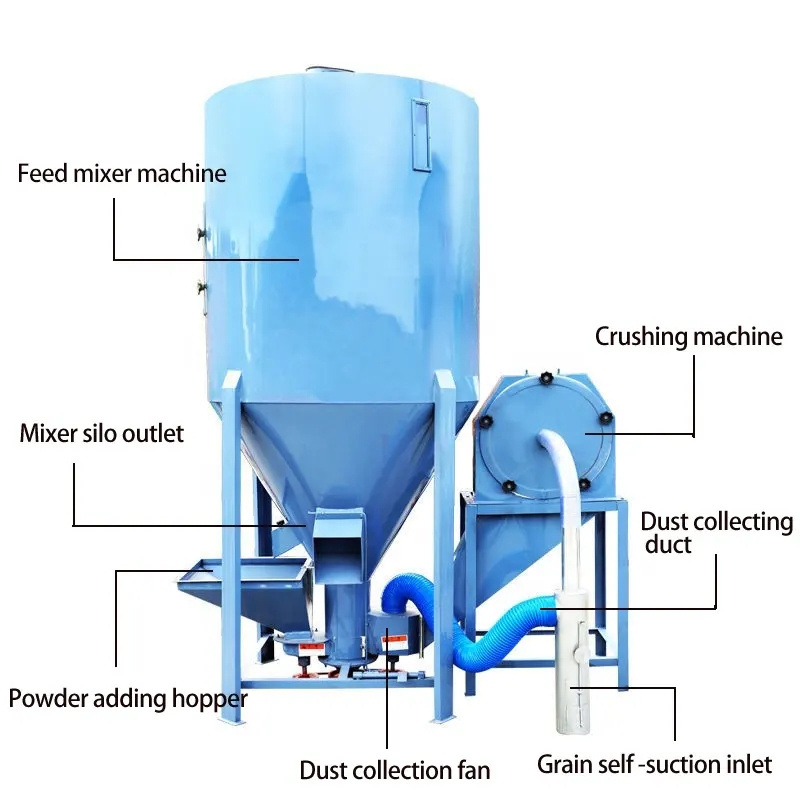

Products Description

Small mash feed grinder and mixer

1. Low cost, small floor area, stable performance and reliable quality;

2. Simple structure, light weight and convenient maintenance;

3. It can realize the crushing and mixing of raw materials and meet the production requirements of most materials.

|

Product name

|

Feed powder production line, mash feed making machine, mash feed grinder and mixer unit

|

|

|

|

|

Color

|

Green, yellow, silver, as your requirement

|

|

|

|

|

Production capacity

|

500kg/batch 1t/b, as you need

|

|

|

|

|

Application

|

Chicken, cattle, pig, duck farms, etc.

|

|

|

|

Specifacation :

1.This kind of machine put the grinder underside, live link, reasonable process, compact instructure,very suitable for

medium-sized cultivation companies and small-scale aquaculture feed processing plants.

2.From top to see the material poured the conic section to be promoted, so many times a cycle. stirring will be made for the door

open, the mixture was unloaded. the mix of material. it takes about 15min.

3.Low Power consumption, occupy space and for loading and unloading, but a long time and place of back base footprint, usually

used for food and food processing plant in the crew.

medium-sized cultivation companies and small-scale aquaculture feed processing plants.

2.From top to see the material poured the conic section to be promoted, so many times a cycle. stirring will be made for the door

open, the mixture was unloaded. the mix of material. it takes about 15min.

3.Low Power consumption, occupy space and for loading and unloading, but a long time and place of back base footprint, usually

used for food and food processing plant in the crew.

Why Choose Us

Pre-sale service:

1.Provide our client with investment guide for free.

2.Provide our client with evaluation investment scheme for free.

3.Free visit to our factory.

4.Design of production line scheme is provided for free.

2.Provide our client with evaluation investment scheme for free.

3.Free visit to our factory.

4.Design of production line scheme is provided for free.

In-sale service:

1. Experienced workers are sent to provide track service when equipment is transported.

2. Experienced technicians or engineers will be sent for on-site installation, adjustment and technical devices according to

clients' engineering requirement.

3. "Operating instruction manual", equipment assembly drawings and wearing parts list in duplicate will be provided for free.

2. Experienced technicians or engineers will be sent for on-site installation, adjustment and technical devices according to

clients' engineering requirement.

3. "Operating instruction manual", equipment assembly drawings and wearing parts list in duplicate will be provided for free.

Post-sale service:

1. On the premise that equipment is operated correctly and in warranty period, we accept repair, exchange, and return items.

2. We provide permanent favorable spare parts for our clients.

3. We provide permanent technology support and related help.

2. We provide permanent favorable spare parts for our clients.

3. We provide permanent technology support and related help.

FAQ

1.Are you manufacturer,yes or not?

Answer: Yes. We have been feed machine manufacturer for 6 years and it will be longer. Now we are capable of producing not only

feed machines but also biomass machines and mineral stone processing machines.

2.Can you accept the customized plan? Can you simplify my plan for reducing costs?

Answer: Of course, our brilliant engineers are waiting for it all the time.

3.What's your MOQ?

Answer: Generally speaking, one is okay, but larger quantity, lower price.

4.What i need know to build a feed processing plant?

Answer: You just need figue out the following questions:

(1)What animal you want to feed? the animal amount? This is used for confirming the production capacity and feed type.

(2)What raw materials you have? material size? material moisture?

(3)Any speical demand? Wait for your contact anytime.

Answer: Yes. We have been feed machine manufacturer for 6 years and it will be longer. Now we are capable of producing not only

feed machines but also biomass machines and mineral stone processing machines.

2.Can you accept the customized plan? Can you simplify my plan for reducing costs?

Answer: Of course, our brilliant engineers are waiting for it all the time.

3.What's your MOQ?

Answer: Generally speaking, one is okay, but larger quantity, lower price.

4.What i need know to build a feed processing plant?

Answer: You just need figue out the following questions:

(1)What animal you want to feed? the animal amount? This is used for confirming the production capacity and feed type.

(2)What raw materials you have? material size? material moisture?

(3)Any speical demand? Wait for your contact anytime.

Tips:To give you the accurate price, there are some details to confirm as follows:

1. What's your raw material?

2. what kind of animal do you feed?

3. The output per hour?

4. Do you also need automatic packing machine?

5. The basic processing technology: Grinding, mixing, pelleting, cooling, crumbling, screeening, packing. Any special requirement,

let me know directly.

6. Our normal voltage is 380V, 50HZ,3phase, if yours is different, tell me yours.

1. What's your raw material?

2. what kind of animal do you feed?

3. The output per hour?

4. Do you also need automatic packing machine?

5. The basic processing technology: Grinding, mixing, pelleting, cooling, crumbling, screeening, packing. Any special requirement,

let me know directly.

6. Our normal voltage is 380V, 50HZ,3phase, if yours is different, tell me yours.

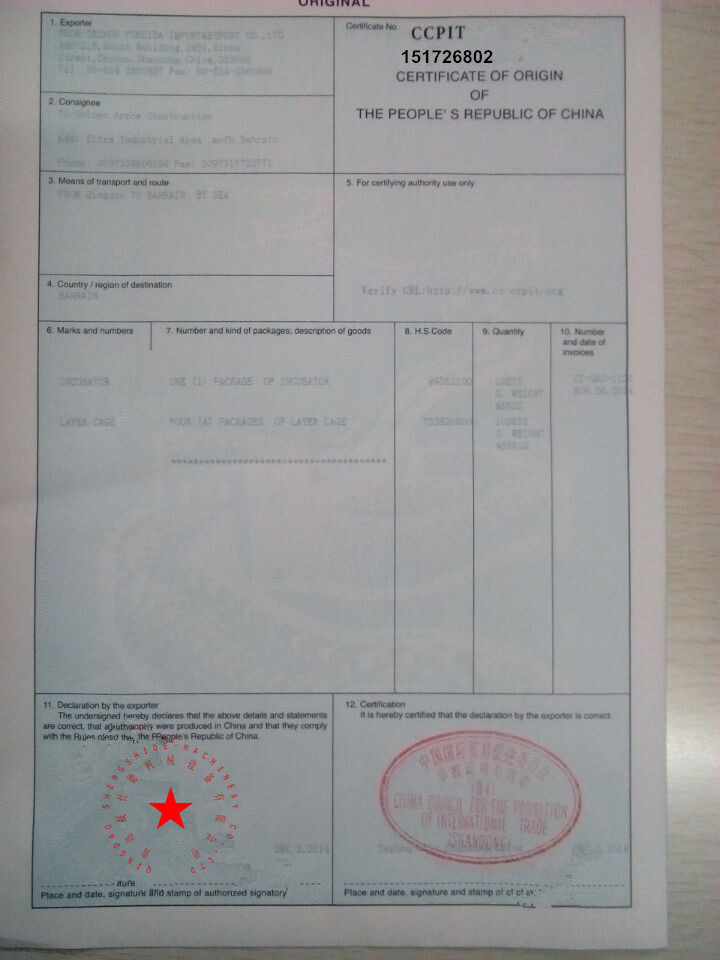

Certification

contact us

Hot Searches