- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Green Pro- T 50

-

Grass Yarn:

-

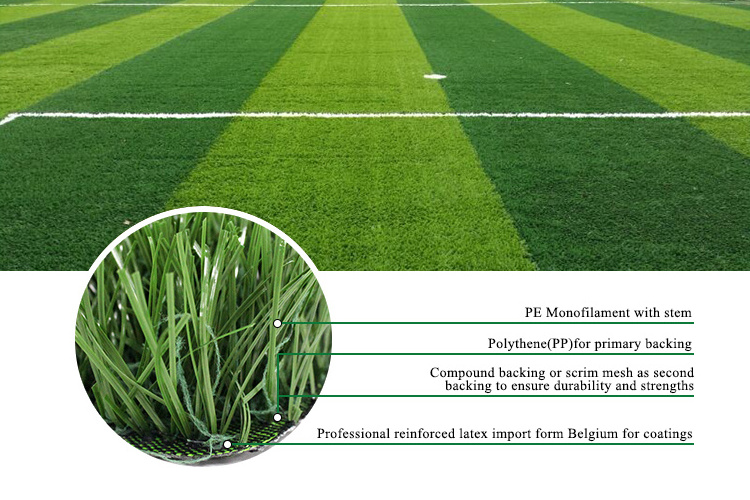

PE Monofilament with stem

-

Dtex:

-

8800

-

Grass Height:

-

40mm,45mm,50mm,55mm,60mm,65mm

-

Guage:

-

5/8, 3/4 available

-

Backing:

-

PP+ Net+ SBR Latex

-

Roll width:

-

2m or 4m available

-

Roll Length:

-

50m or as requested

-

Certificate:

-

Labosport, SGS, CE, CTA, ISO9001, ISO14001

Quick Details

-

Color:

-

green, Dark green, light green

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

CGT

-

Model Number:

-

Green Pro- T 50

-

Grass Yarn:

-

PE Monofilament with stem

-

Dtex:

-

8800

-

Grass Height:

-

40mm,45mm,50mm,55mm,60mm,65mm

-

Guage:

-

5/8, 3/4 available

-

Backing:

-

PP+ Net+ SBR Latex

-

Roll width:

-

2m or 4m available

-

Roll Length:

-

50m or as requested

-

Certificate:

-

Labosport, SGS, CE, CTA, ISO9001, ISO14001

PE Monofilament artificial turf 50mm colors interlocking football /soccer ground synthetic turf indoor

PE Monofilament artificial turf 50mm colors interlocking football /soccer ground synthetic turf indoor

| Color | Dark green, light green |

| Grass Height | 40mm,45mm,50mm,55mm,60mm,65mm |

| Grass Yarn | PE Monofilament (W shape) |

| Dtex | 12000 |

| Gauge | 3/8, 5/8 available |

| Stitch Rate | 130 to 250stitches/m or as requested |

| Color | Dark green, light green |

| Backing | PP+ Net+ SBR Latex |

| Roll width | 2m or 4m available |

| Roll length |

50m or as requested

|

| Packing | In roll with film covered |

We are a professional comprehensive sports facility Manufacturer in Guangzhou.

We are a professional comprehensive sports facility Manufacturer in Guangzhou.

Our company is specialized in artificial grass for 10 years , Many kinds of artificial grass can be available and We also can offer the best solution for you according to the usage, price and material.

Characteristics :

1. Excellent rebound and softness performance, ensure the safety of kneels and skin;

2. Achieve sports standard of natural lawn, comparable with natural turf fields;

3. Good drainage, anticorrosive anti-moldy, fastness and UV resistance;

4. Excellent anti-wear performance can increase use frequency of fields;

5. Easy installation and maintenance;

6. All weather usability;

7.16 different types of artificial grass for selection.

Prepared before Installation :

How to Installation

1.1. Inspection :

Inspect the foundation to ensure it has a flat and smooth surface and appropriate slopes, making sure the

foundation is qualified for installing artificial turf;

1.2. Measuring :

Locate the centers of the ground and the two semicircles, and according to these three centers locate the

intersecting point of half-way lines and touchlines, and then determine the positions of functional lines

and spot by using Pythagorean proposition;

2. Turf layout :

According to drawing, position the turf rolls on the exact places along the touchline. The turf with white

lines should be placed at the half-way lines and base line, and then lay out the rolls in order;

3. Preparing functional line :

Cut white turf piece into strips(width to be as per actual need) for white functional lines(half-way lines,

base lines etc.), and put them aside preparing for Green Artificial Grass Carpet installation;

4. Seaming :

The adiacent turf rolls must be join together with 20~30mm excess on both sides, then cut the excess

part with a special cutting knife on the joint center and trim the cut to make the turf join perfectly

together. After trimming, place the seam tape on the foundation surface and make the joint line of turf

right on the middle of the seam tape. And then apply the adhesive to seam tape evenly with a rubber

spreader, and press down the turf on both sides of the seam tape firmly;

5.1. Installing functional lines :

Measure and re-position the functional line on the turf that has been all well joined on the ground. Cut

the turf out and place the seam tape beneath the cuts, then spread the adhesive on the seam tape and

install the well-prepared functional lines, press it firmly to ensure the immobility.

5.2. Trimming :

Inspect the finished lawn, if any uneven found, cut it open, pull it straight and cut the excess away.

And rejoin it with adhesive;

6. Infilling sand :

Place the sand piles on the finished lawn on different spots evenly at a distance of 4m from each other,

then spread them evenly on the lawn(the quantity if sand depends on the pile height of the turf).

Afterwards, use the combing machine to sweep the sand into the fibers and to comb uo the fibers. Do

this process once longitudinally and transversely.

7. Infill rubber granules :

After sand infilling, Place the rubber granules piles on the lawn on different spots evenly at a distance

of 4m from each other, then spread them evenly on the lawn(the quantity of sand depends on the pile

height of the turf). Afterwards, use the combing machine to sweep the sand into the fibers and to comb

up the fibers. Do this process once longitudinally and transversely.

8. Combing :

Once the infilling is finished, comb the turf once more with the combing machie to make the fibers

point up to the sky.

9. Inspection :

Inspect the entire finished lawn as per concerned standards and requirement. If any defects found,

correct it.