- Product Details

- {{item.text}}

Quick Details

-

Use:

-

Warehouse Rack

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

HYD

-

Model Number:

-

HYD-CR

-

Depth:

-

1.5-3.5mm

-

Weight Capacity:

-

500-4000 kg / layer

-

Width:

-

customized

-

Height:

-

customized

-

Product name:

-

Radio Shuttle Racking

-

Usage:

-

Warehouse Storage System

-

Color:

-

Customized

-

Structure:

-

Assembled Freely

-

Loading Capacity:

-

500-4000kg

-

Beam:

-

Adustable

-

Surface treatment:

-

Powder Coated

-

Style:

-

Modern Customized

-

Packing:

-

Plastic Film Protection

-

Certification:

-

CE/ISO

Quick Details

-

Type:

-

Cantilevered

-

Material:

-

Steel

-

Feature:

-

Corrosion Protection

-

Use:

-

Warehouse Rack

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

HYD

-

Model Number:

-

HYD-CR

-

Depth:

-

1.5-3.5mm

-

Weight Capacity:

-

500-4000 kg / layer

-

Width:

-

customized

-

Height:

-

customized

-

Product name:

-

Radio Shuttle Racking

-

Usage:

-

Warehouse Storage System

-

Color:

-

Customized

-

Structure:

-

Assembled Freely

-

Loading Capacity:

-

500-4000kg

-

Beam:

-

Adustable

-

Surface treatment:

-

Powder Coated

-

Style:

-

Modern Customized

-

Packing:

-

Plastic Film Protection

-

Certification:

-

CE/ISO

Product Introduction

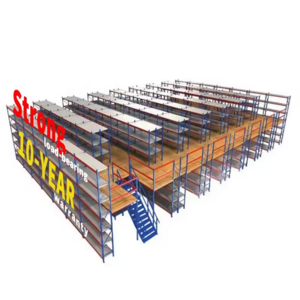

Radio Shuttle Racking

—— Common Design ——

Strong bearing capacity, easy installation, expansion space & durability.

Operating temperature: 0°C to +45°C

Operating temperature: 0°C to +45°C

Product Advantages

No.1 / Rigorous Material Selection

Strict selection of materials, the use of Q235 structural steel, is a large steel group in china to provide steel.

Q235: low carbon content, good comprehensive performance, strength, plasticity and welding are well matched.

Q235: low carbon content, good comprehensive performance, strength, plasticity and welding are well matched.

No.2 / Cost Effective And Time-Saving

Forklifts are not required to enter the racking area, shuttles can work continuously while operator handles the pallet with

forklift.Compared with other types of shelves, the overall investment is less, for example: warehouse lighting requirements. .

forklift.Compared with other types of shelves, the overall investment is less, for example: warehouse lighting requirements. .

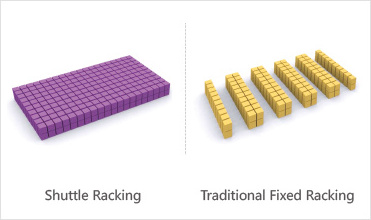

No.3 / Maximum Floor Space Utilization

The aisle for forklift in selective racks is eliminated, space utilization increased almost 100%.

No.4 / Strong Bearing Capacity

Up to 1500 kg/pallet could be handled in the system

No.5 / Secure Storage And Pickup

Forklifts are not required to enter the racking area, Low level of risks or damage to the racks and operating staff.

No.6 / Built In Safety Feature

Built in safety feature like pallet guide centralizers, rail end stoppers, photoelectric sensors, etc.

No.7 / Flexible And Convenient Pickup

FIFO and FILO

For FIFO, the warehousing end can be easily switched, when all the goods in the roadway are not taken out, the warehousing can be

moved with one key for convenient operation.LIFO Handling – Ideal for durable product without a use by date, improves productivity, increases the warehouse capacity. FIFO

Handling – Ideal for perishable goods, requires two aisles (one for loading, one for unloading)

moved with one key for convenient operation.LIFO Handling – Ideal for durable product without a use by date, improves productivity, increases the warehouse capacity. FIFO

Handling – Ideal for perishable goods, requires two aisles (one for loading, one for unloading)

— Radio Shuttle Racking >www.heavyracking.com< Warehouse Storage Racking —

No.8 / High Precision Automatic Pickup

Automatically handles pallet picking and retrieval with high precision.

No.9 / 40m Deep In The Lane

The pallet configuration can go up to 40m deep in the lane

No.10 / Strong & Durable, Beautiful Rust Proof

The shelves are made of cold-rolled steel material, which is electrostatic sprayed after pickling and phosphating at high temperature.

No.11 / Easy Installation And Maintenance

Structural Principles

High-Density Pallet Storage Solution

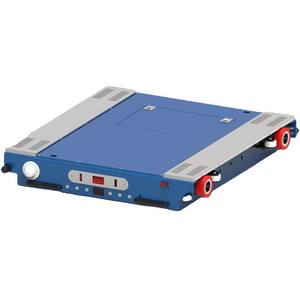

Radio shuttle racking system is a semi-automated, high-density pallet storage solution, working with radio shuttle cart and forklift.

With a remote control, operator can request radio shuttle cart to load and unload pallet to requested position easily and quickly.

— Radio Shuttle Racking >www.heavyracking.com< Warehouse Storage Racking —

Used

Explosion-Proof Storage

Explosion-Proof Shuttle Rack+Explosion-Proof Shuttle Car

Cold Chain Racks

The pallet configuration can go up to 40m deep in the lane

Radio shuttle racking + four wheel shuttle / eight wheel shuttle

Radio shuttle rack & four-way shuttle

Radio Shuttle Rack+ Shuttle Carrier System

Radio Shuttle Rack + Stacker Crane

Radio Shuttle Rack +AGV

Racking Protection

Warehouse Storage Rack Flexible Anti-Collision System

Our Company

Anhui Huayide Intelligent Storage Equipment Co., Ltd. devotes itself to the design and manufacture of storage equipment. We are specialized in producing various pallet rack, cantilever rack, electric mobile rack storage system, mezzanine rack, shuttle cart automatic storage system, drive in rack, carton flow rack, stacking rack ,AS/RS and other related storage equipment system.

We have formed a variety of logistics solutions covering pharmaceutical and chemical, beverage and food, home appliances, the third Party Logistics and other industries. Our products comply to EN, ANSI, JIS, and FEM standard. We are committed to providing our customers with the best warehouse planning services.

The participant and constitutor of national standard for logistics.

Our factory established in march 1993, is the pioneer in rack designing and production in china.

Exporting percentage up to 50%, products accepted and popular in japan, europe and america.

Our Advantages

|

Ensure the quality of Huayide racking products

|

|

|

|

|

||||

|

1 / The raw material of the shelf is customized from China's large steel group of high quality carbon steel, durable and strong, to ensure the quality of the product from the source.

|

|

|

|

|

||||

|

2 / The shelf welding adopts dioxygen protection welding, the welding joint has good cracking resistance, small welding

deformation, beautiful forming, and does not need slag cleaning. |

|

|

|

|

||||

|

3 / Each column and beam of the shelf are designed by professional personnel with professional technology and cut by professional equipment, so as to ensure the accurate size of the shelf.

|

|

|

|

|

||||

|

4 / Professional spray before treatment, oil removal, rust removal, phosphating, powder, and then in high temperature oven baking molding, wear-resistant, rust proof.

|

|

|

|

|

||||

Cases

FAQ

1. Q: What's your trading terms?

1) Payment terms: T/T 30% deposit after order confirmed, 70% balance paid against bill of lading.

2) Lead time: normally in 20-25 days after deposit received.

3) Sample policy: samples are always available for each model. Samples can be ready in 7-15 days once payment received.

4) Shipping port: Shanghai / Nanjing Port

2. Q: What is your service?

1) Your inquiry related to our products or price will be replied in 12 hours.

2) Well-trained and experienced staffs to answer all your inquiries in fluent English.

3) OEM & ODM, any your customized racking we can help you to design product.

4) We have very experienced professional engineers to make best solutions.

3. Q: Do you have any reference for assembling the products ?

Yes, we offer assembly manual and we can provide you instructor engineer to your warehouse if needed.

4. Q: What's the international trading process?

Design drawing → Confirm drawing → Quotation → PI → Confirm PI → Arrange 30% deposit → Manufacture → QC inspect → Pay balance→Shipping.

5. Q: What's your advantage?

1) rush order we can fast delivery.

2) factory direct sale competitive price.

3) experienced professional engineers.

6. Q: How does charge tooling fee (cost of opening new mold)?

For the production of necessary tooling requirement, charges the cost before the first order for opening new mold, and the cost

will be partially or fully refunded after certain quantity of orders.

1) Payment terms: T/T 30% deposit after order confirmed, 70% balance paid against bill of lading.

2) Lead time: normally in 20-25 days after deposit received.

3) Sample policy: samples are always available for each model. Samples can be ready in 7-15 days once payment received.

4) Shipping port: Shanghai / Nanjing Port

2. Q: What is your service?

1) Your inquiry related to our products or price will be replied in 12 hours.

2) Well-trained and experienced staffs to answer all your inquiries in fluent English.

3) OEM & ODM, any your customized racking we can help you to design product.

4) We have very experienced professional engineers to make best solutions.

3. Q: Do you have any reference for assembling the products ?

Yes, we offer assembly manual and we can provide you instructor engineer to your warehouse if needed.

4. Q: What's the international trading process?

Design drawing → Confirm drawing → Quotation → PI → Confirm PI → Arrange 30% deposit → Manufacture → QC inspect → Pay balance→Shipping.

5. Q: What's your advantage?

1) rush order we can fast delivery.

2) factory direct sale competitive price.

3) experienced professional engineers.

6. Q: How does charge tooling fee (cost of opening new mold)?

For the production of necessary tooling requirement, charges the cost before the first order for opening new mold, and the cost

will be partially or fully refunded after certain quantity of orders.

— Radio Shuttle Racking >www.heavyracking.com< Warehouse Storage Racking —

Hot Searches