(1) Excellent adhesion to various substrates.

(2) Cures fast, shortens heat or cold setting time.

(3) Foam percentage 30-100%, benefits to fill cracks between the substrates.

(4) Suitable for scraping operation.

(5) Solvent free, environmental friendly.

(6) Good humidity and heat resistance.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

Flexibond

-

Model Number:

-

Flexibond 8207/8207W

-

Type:

-

Polyurethane glue

-

Classification:

-

Room Curing and Thermosetting

-

Morphology:

-

Solvent Free

-

Application:

-

Building Materials

-

Material:

-

Polyurethane

-

Color:

-

Light Yellow

-

Characteristic:

-

Low Viscosity, Good Penetration

-

Export Markets:

-

Global

-

Shelf life:

-

6-12months

-

Function:

-

Bonding+Sealing

-

Application range:

-

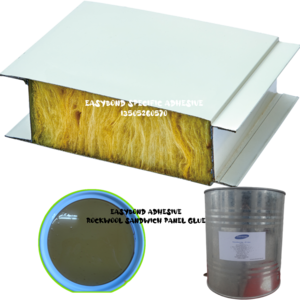

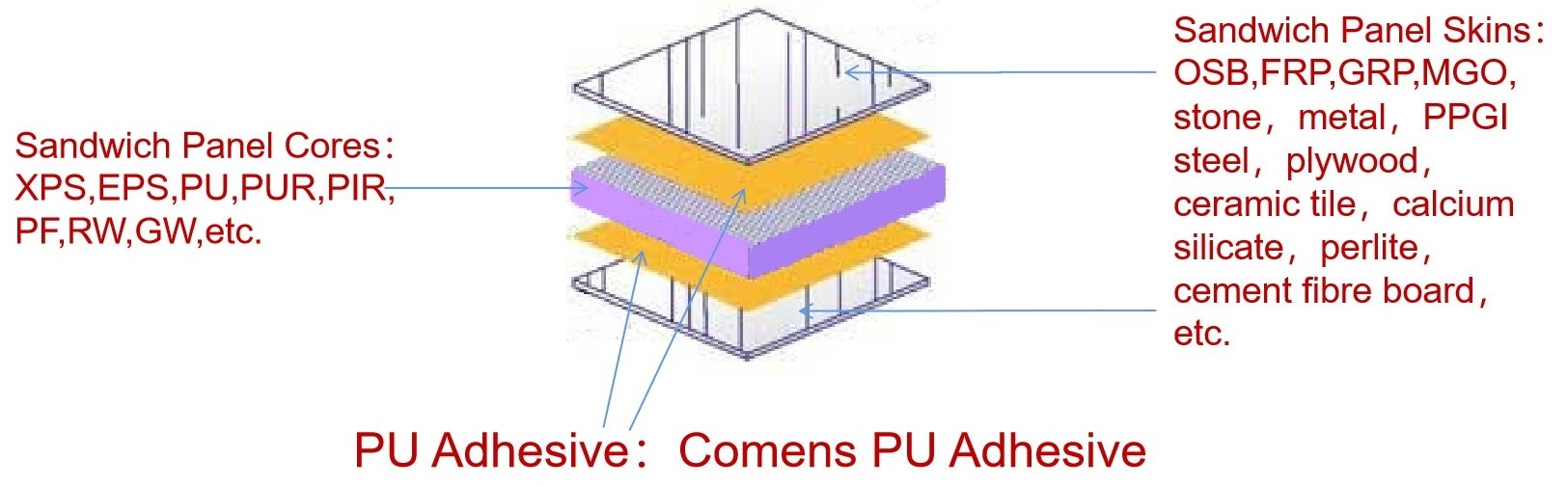

EPS/XPS/GRP/FRP/RW/GW/PU panels etc.

Quick Details

-

CAS No.:

-

9009-54-5

-

MF:

-

-C3H8N2O-

-

EINECS No.:

-

210-898-8

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

Flexibond

-

Model Number:

-

Flexibond 8207/8207W

-

Type:

-

Polyurethane glue

-

Classification:

-

Room Curing and Thermosetting

-

Morphology:

-

Solvent Free

-

Application:

-

Building Materials

-

Material:

-

Polyurethane

-

Color:

-

Light Yellow

-

Characteristic:

-

Low Viscosity, Good Penetration

-

Export Markets:

-

Global

-

Shelf life:

-

6-12months

-

Function:

-

Bonding+Sealing

-

Application range:

-

EPS/XPS/GRP/FRP/RW/GW/PU panels etc.

Description

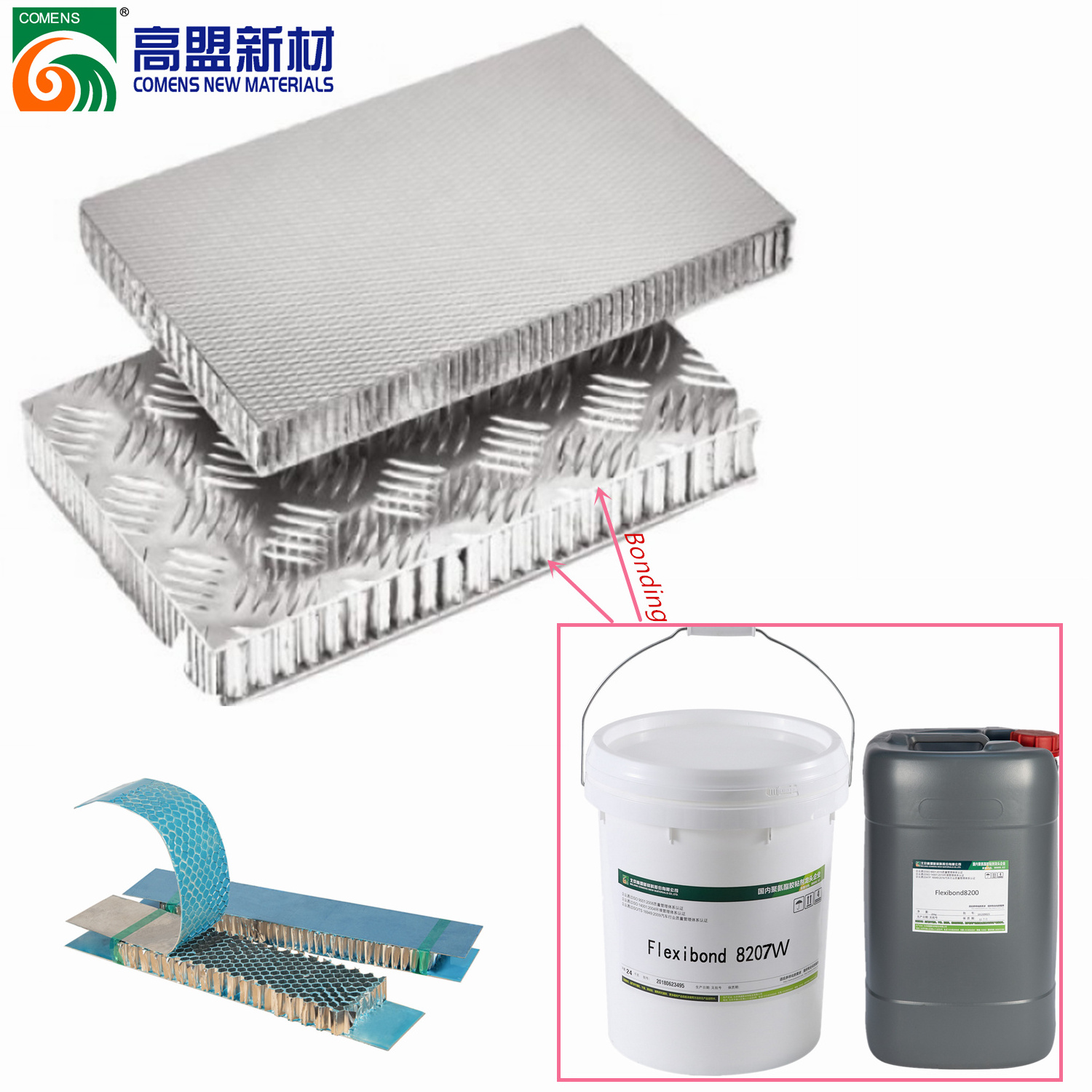

Flexibond 8207 is a two-component polyurethane adhesive which is widely applied to manufacture heat-insulation and decoration integrated plate, ceiling board and metal partition of clean rooms.

It is suitable for various substrates, such as galvanized sheets, calcium silicate board, glass magnesium board, rook wool, PU foam, expanded polystyrene foam board, extruded polystyrene foam board, phenolic board, etc. The volume of adhesive will be expanded during the curing process.

Advantages

FLEXIBOND 8207 / FLEXIBOND 8200

FLEXIBOND 8207W / FLEXIBOND 8200

(1) Low viscosity,Cure fast,Very suitable for winter use.

(2)Excellent adhesion to various substrates.

(3)Cures fast, shortens heat or cold setting time.

(4) Foam percentage 50-100%,benefits to fill cracks between the substrates.

(5) Solvent free, environmental friendly.

(6) Good humidity and heat resistance.

Technical Data Sheet

|

Flexibond8207/Flexibond8200

|

Component A(Resin)

|

Component B(Hardener)

|

||

|

Curing mechanism

|

Poly addition

|

|

||

|

Chemical base

|

Multiplehydroxyl compound

|

PAPI

|

||

|

Color

|

White

|

Brown

|

||

|

The color after mixing

|

Light yellow

|

|

||

|

Density (before curing)

|

1.7g/ cm 3

|

1.2g/ cm 3

|

||

|

Viscosity

|

1

5000-20000mPa.s (Brookfield – RVT 6/20)

|

200-300mpa.s(Brookfield – RVT 2/50)

|

||

|

Viscosity (after mixing)

|

5

000-8000mpa.s (Brookfield–RVT 6/20)

|

|

||

|

Mixing ratio (by weight)

|

100

|

20

|

||

|

Pot life (23℃)

|

4

0-60mins

|

|

||

|

Open time (23℃, 50%RH)

|

6

0-80mins

|

|

||

|

Hardness shore D (GB/T 531-2008)

|

Approx 60

|

|

||

|

Shear strength (GB/T 7124-2008)

|

≥6Mpa (Aluminum alloy)

|

|

||

|

Shelf life (unopened below 25℃)

|

12 months

|

6 months

|

||

|

*Testing temperature 23℃ and 50% r.h.

|

|

|

||

|

Flexibond8207W/Flexibond8200

|

Component A(Resin)

|

Component B(Hardener)

|

||

|

Curing mechanism

|

Poly addition

|

|

||

|

Chemical base

|

Multiplehydroxyl compound

|

PAPI

|

||

|

Color

|

White

|

Brown

|

||

|

The color after mixing

|

Light yellow

|

|

||

|

Density (before curing)

|

1.55g/ cm 3

|

1.2g/ cm 3

|

||

|

Viscosity

|

15

000-20000mpa.s (Brookfield – RVT 6/20)

|

200-300mpa.s (Brookfield – RVT 2/50)

|

||

|

Viscosity (after mixing)

|

5

000-10000mpa.s (Brookfield–RVT 6/20)

|

|

||

|

Mixing ratio (by weight)

|

100

|

20

|

||

|

Pot life (23℃)

|

30

-50mins

|

|

||

|

Open time (23℃, 50%RH)

|

45

-60mins

|

|

||

|

Hardness shore D (GB/T 531-2008)

|

Approx 70

|

|

||

|

Shear strength (GB/T 7124-2008)

|

≥10Mpa (Aluminum alloy)

|

|

||

|

Shelf life (unopened below 25℃)

|

12 months

|

6 months

|

||

|

*Testing temperature 23℃ and 50% r.h.

|

|

|

||

Application

Scope of application

Bonding Substrate

Application Note

(1)Preparation:

Prepare a clean and dry drum for mixing the adhesive.

Mixing tool: Sticks for manual mixing or electric mixer.

Electronic scale: It would be better if the electronic scale can accurately weight to one decimal.

(2)Substrates Surface Treatment:

The substrates should be clean and dry and of no grease, dust, or other contaminations. The substrates can be cleaned by alcohol or acetone. If the metal surface is coated with primer, or the surface is polished, the adhesion can be improved significantly.

(3)Flexibond 8207/Flexibond 8200=5: 1

The resin (8207) should be uniformly stirred before it is mixed with the hardener (8200). Mix the two components uniformly. Mix for 1-2 more minutes after the two components color is well mixed. Use up the mixer as soon as possible before its pot life, or less frequent principle can be taken.

(4)Adhesive Coating:

The adhesive can be coated with spreading machine, rollers or serrated scrapers manually. The adhesive should be coated uniformly on the substrate surface. The recommended dosage is 200-400G/M2. The dosage varies with the roughness of the substrate surface.

The adhesive should be coated within its pot life.

(5)Pressing:

Substrates have been coated with adhesive should be pressed within open time, or the adhesion strength will be affected. Raise the compounding pressure as high as possible without affecting the material forming.

(6)Pressing time

The curing speed and the time to form adhesion vary with the temperature. The curing speed is slower and it takes longer time for pressing as the temperature is lower; The curing speed is faster and it takes shorter time for pressing as the temperature is higher. The pressing time is 4 hours under 23℃.

(7) Working Condition

Recommended working condition: Temperature 5-30, relative humidity <80. The curing speed will be affected if the temperature is too low. And too much bubble will be formed if the humidity is too high.

(8) Clean

Recommended Cleaner: Acetone, butanone.

Prepare a clean and dry drum for mixing the adhesive.

Mixing tool: Sticks for manual mixing or electric mixer.

Electronic scale: It would be better if the electronic scale can accurately weight to one decimal.

(2)Substrates Surface Treatment:

The substrates should be clean and dry and of no grease, dust, or other contaminations. The substrates can be cleaned by alcohol or acetone. If the metal surface is coated with primer, or the surface is polished, the adhesion can be improved significantly.

(3)Flexibond 8207/Flexibond 8200=5: 1

The resin (8207) should be uniformly stirred before it is mixed with the hardener (8200). Mix the two components uniformly. Mix for 1-2 more minutes after the two components color is well mixed. Use up the mixer as soon as possible before its pot life, or less frequent principle can be taken.

(4)Adhesive Coating:

The adhesive can be coated with spreading machine, rollers or serrated scrapers manually. The adhesive should be coated uniformly on the substrate surface. The recommended dosage is 200-400G/M2. The dosage varies with the roughness of the substrate surface.

The adhesive should be coated within its pot life.

(5)Pressing:

Substrates have been coated with adhesive should be pressed within open time, or the adhesion strength will be affected. Raise the compounding pressure as high as possible without affecting the material forming.

(6)Pressing time

The curing speed and the time to form adhesion vary with the temperature. The curing speed is slower and it takes longer time for pressing as the temperature is lower; The curing speed is faster and it takes shorter time for pressing as the temperature is higher. The pressing time is 4 hours under 23℃.

(7) Working Condition

Recommended working condition: Temperature 5-30, relative humidity <80. The curing speed will be affected if the temperature is too low. And too much bubble will be formed if the humidity is too high.

(8) Clean

Recommended Cleaner: Acetone, butanone.

Specification

Resin: 25kg/drum, 1000kg/drum

Hardener: 5kg/drum, 200kg/drum

The packaging can be adjusted according to customer’s requirement.

Packaging & Shipping

Our Partners

Hot Searches