- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

5454*1825*1242mm

-

Weight:

-

1012 KG

-

Name:

-

laboratory gold seperator shaking table

-

Keywords:

-

shaking table

-

Certification:

-

ISO

Quick Details

-

Production Capacity:

-

95%

-

Place of Origin:

-

China

-

Brand Name:

-

Huahong

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

5454*1825*1242mm

-

Weight:

-

1012 KG

-

Name:

-

laboratory gold seperator shaking table

-

Keywords:

-

shaking table

-

Certification:

-

ISO

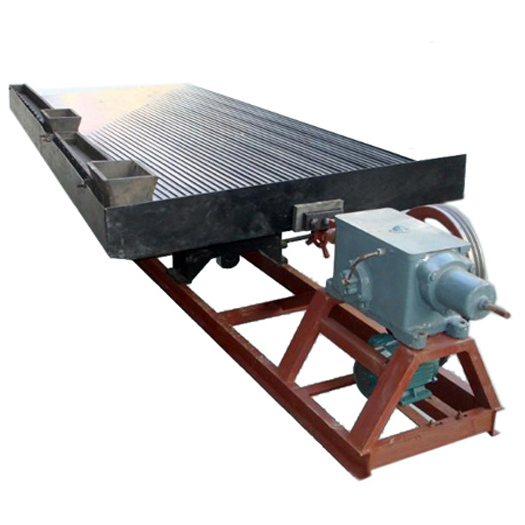

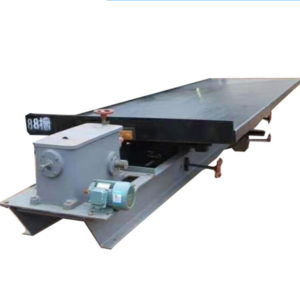

Product description

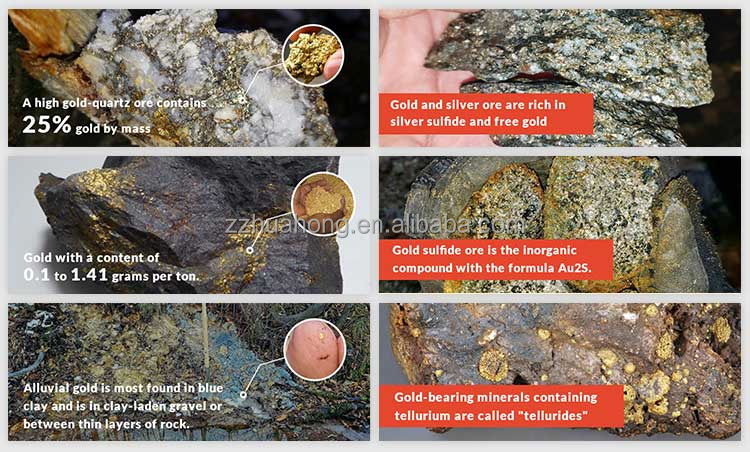

Shaking bed is a mine selecting machine for fine materials working by gravity. It is widely used in selection of Tin, tungsten, gold, silver, lead, zinc, tantalum, niobium, iron, manganese, ferrotitanium and coal. Our company has long history of table concentrator production; we provide variety oftable concentrators with high processing capacity, high recovery rate and high enrichment ratio..

Product Application

The shaking bed used to classify the granularity from 2-0.02 millimeters ore and ore slime of tungsten, the tin, the niobium, the manganese, the chromium, the titanium, the lead, the zinc, the gold, the iron(red iron, brown iron)and so on the metallic minerals.

|

Model

|

L-S (6-S)

|

Water quantity (t/h)

|

0.4-0.8

|

|

Stroke (mm)

|

10-30

|

Table size (mm)

|

1520*1825*4500

|

|

Frequency of stroke

|

240-360

|

Motor (KW)

|

1.1

|

|

Horizontal cape

|

0-8

|

Treating capacity (t/h)

|

0.5-1.2

|

|

Feed size (mm)

|

2-0.074

|

Weight (kg)

|

1012

|

|

Min density (%)

|

15-30

|

Dimension (mm)

|

5454*1825*1242

|

Working principle

Shaking bed consists of a slightly inclined deck to which the materials are introduced at the feed box and distributed. At the same time, wash water is distributed along the banlance of the feed side from a launder. The table does a slow forward stroke and a rapid return, vibrating longitudinally by a mechanism which causes the mineral particles to "crawl" along the deck parallel to the direction of motion. The minerals are thus subjected to two forces due to the table motion and the flowing film of water at right angle to it. The net effect is that the particles move diagonally across the deck from the feed end, and since the effect of the flowing film depends upon the size and density of the particles, they will fan out on the table. The smaller denser particles ride highest towards the concentrate launder at the far end, while the larger lighter particles are washed into the tailings launder which runs along the length of the table.

Main Features

B: High concentration ratio

C: Fast installation

D: Easy operation

E: Deck constructed of fiber glass

F: Three different decks to choose

G: Long lifetime

H: Adjustable stroke length and speed