- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Gaodetec

-

Dimension(L*W*H):

-

4000*2000*1800mm

-

Weight (KG):

-

4100 kg

-

Product Name:

-

High Pressure Cleaning Machine

-

Application:

-

Cleaning, Removal, Pretreatment

-

Flow rate:

-

60L/min

-

Speed:

-

1750r/min

Quick Details

-

Cleaning Process:

-

Cold Water Cleaning

-

Power:

-

182kw

-

Max. Pressure:

-

1300bar

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Gaodetec

-

Dimension(L*W*H):

-

4000*2000*1800mm

-

Weight (KG):

-

4100 kg

-

Product Name:

-

High Pressure Cleaning Machine

-

Application:

-

Cleaning, Removal, Pretreatment

-

Flow rate:

-

60L/min

-

Speed:

-

1750r/min

Application

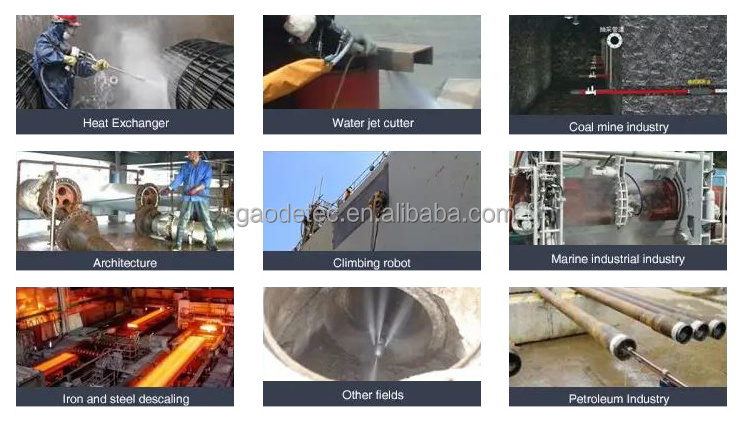

High pressure water jet cleaning machine application

1.

Cleaning

: hull cleaning, aluminum template cleaning, pipe cleaning, condenser, heat exchanger, etc. descaling cleaning.

2.

Removal

: ship paint removal, landmark line removal, phosphorus removal in steel mills, chloride removal in concrete.

3.

Pretreatment

: highway overlay treatment, concrete surface treatment, marine surface treatment.

4. Others: high-pressure water jet cutting, sewer dredging, high-pressure water roughening, cement demolition projects, spunlace non-woven fabrics, water atomization powder.

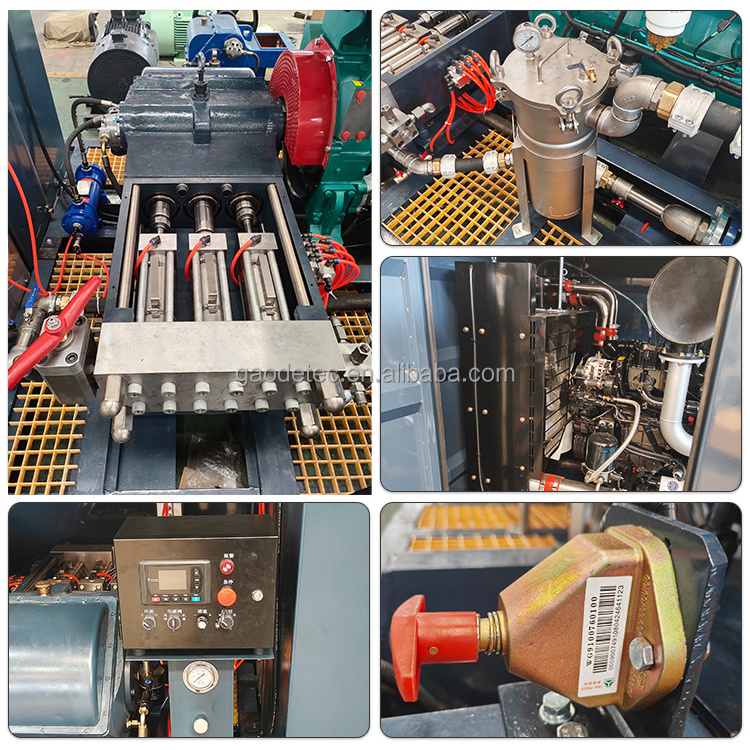

Products Description

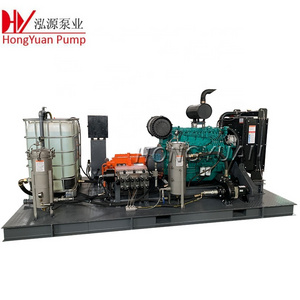

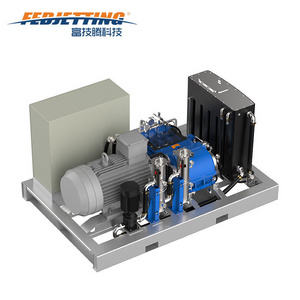

Diesel high pressure cleaners high pressure water jet cleaning machine

High-pressure cleaning machine is a versatile and efficient tool for deep cleaning outdoor surfaces, providing a quick and

effective solution for removing dirt and grime.

effective solution for removing dirt and grime.

It is highly effective in removing stubborn stains, dirt, and grime, as the high-pressure water can penetrate and dislodge even the toughest residues. They are also time-efficient, as they can clean large areas quickly and efficiently.

|

Flow rate

|

60 L/min

|

29L/min

|

||

|

Operating pressure

|

1300bar

|

1600bar

|

||

|

Plunger diameter

|

24mm

|

16mm

|

||

|

Diesel engine power

|

182KW

|

100KW

|

||

|

Diesel engine speed

|

1750r/min

|

1800r/min

|

||

|

We can also customize according to your requirements.

|

|

|

||

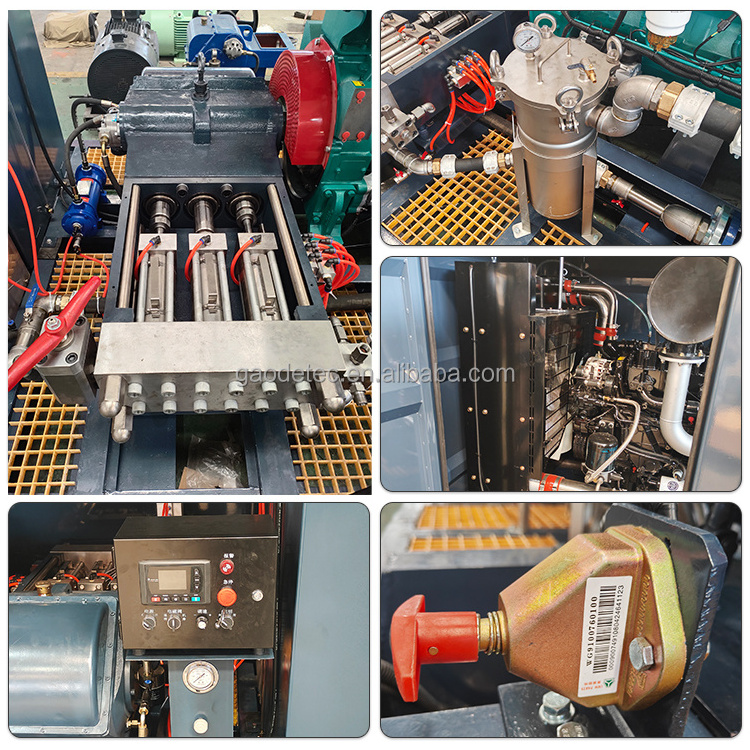

Feature

1. Stainless steel pump head adapted to alternating stress.

2. The middle rod seal is used in combination with two different types of seals.

3. Specially developed plunger seal.

4. Carbide plunger.

5. The crankshaft is designed according to the finite element method to ensure the reliability during operation.

6. The design of herringbone gear is used inside to offset the axial force.

7. External multi-point forced lubrication system to ensure sufficient lubrication of each contact surface.

8. The lubrication system is equipped with a relief valve, which can ensure the oil pressure at 5bar at different input speeds.

9. Flexible plunger connection, effectively reducing the risk of eccentric wear.

Accessories

Different types of nozzles

1. We have a variety of nozzle types to choose from, and different opening patterns can be selected according to your application, pressure and flow.

2. The nozzle is made of steel, precision machining, no rust, strong wear resistance.

3. It is suitable for all kinds of complex and different diameter pipelines, and completes all-round pipeline cleaning operations.

Hot Searches