- Product Details

- {{item.text}}

Quick Details

-

Ultimate Strength (≥ MPa):

-

0.04

-

Density (kg/m³ ):

-

128

-

Length:

-

3600/7200mm

-

Working Temperature:

-

1050C-1350C

-

Fiber Diameter:

-

2-5um

-

Shrinkage (1800 ℉, 3h):

-

2.8 (24hours)

-

Thermal Conductivity:

-

0.09-0.18w/(m.k)

-

Model Number:

-

Ceramic Fiber Blanket

-

Brand Name:

-

LUYANGWOOL

-

Place of Origin:

-

Shandong, China

-

Product name:

-

Ceramic Wool Insulation Blanket

-

Raw material:

-

Ceramic Fiber Bulk

-

Package:

-

Carton Box or Woven Bag

-

Feature:

-

Heat Insulation

-

Bulk Density:

-

96~160(kg/m3)

-

Sample:

-

Provided for free

-

Advantage:

-

Double Needled

-

Material:

-

Ceramic Fiber Bulk Wool

-

Port:

-

QINGDAO

-

Producer:

-

Luyang

Quick Details

-

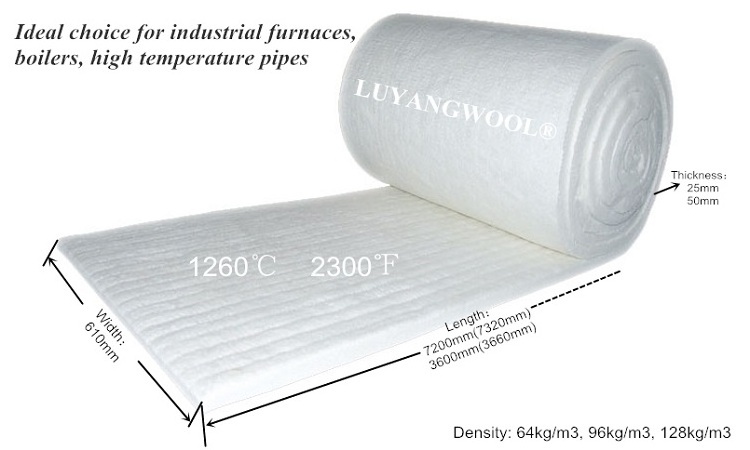

Thickness:

-

10-50mm

-

Width:

-

610/1220mm

-

Chemical Composition:

-

AL2O3+SIO2

-

Ultimate Strength (≥ MPa):

-

0.04

-

Density (kg/m³ ):

-

128

-

Length:

-

3600/7200mm

-

Working Temperature:

-

1050C-1350C

-

Fiber Diameter:

-

2-5um

-

Shrinkage (1800 ℉, 3h):

-

2.8 (24hours)

-

Thermal Conductivity:

-

0.09-0.18w/(m.k)

-

Model Number:

-

Ceramic Fiber Blanket

-

Brand Name:

-

LUYANGWOOL

-

Place of Origin:

-

Shandong, China

-

Product name:

-

Ceramic Wool Insulation Blanket

-

Raw material:

-

Ceramic Fiber Bulk

-

Package:

-

Carton Box or Woven Bag

-

Feature:

-

Heat Insulation

-

Bulk Density:

-

96~160(kg/m3)

-

Sample:

-

Provided for free

-

Advantage:

-

Double Needled

-

Material:

-

Ceramic Fiber Bulk Wool

-

Port:

-

QINGDAO

-

Producer:

-

Luyang

Product Description

LUYANGWOOL® CERAMIC FIBER BLANKET / RCF Blanket

Luyangwool® ceramic fiber blanket is high strength, needled insulating blanket that is made from Luyangwool® ceramic fiber bulk.The combination of long spun fibers and needling operation produce tough, resilient and strong blankets, which resist tearing both before and after heating.

Luyangwool® ceramic fiber blanket is completely inorganic and available in a variety of temperature grades, densities, and sizes. Luyangwool® ceramic fiber blanket can be folded, compressed and encapsulated to produce module.

Luyangwool® ceramic fiber blanket is completely inorganic and available in a variety of temperature grades, densities, and sizes. Luyangwool® ceramic fiber blanket can be folded, compressed and encapsulated to produce module.

Features

Excellent thermal shock resistance

Excellent thermal stability

High tensile strength

Low thermal conductivity

Low heat storage

Excellent thermal shock resistance

Excellent thermal stability

High tensile strength

Low thermal conductivity

Low heat storage

|

Product name

|

LUYANGWOOL®

Ceramic fiber blanket

Aluminium silicate fiber blanket

|

|

Classification

t

emperature

|

1260℃/1350℃/1430℃

|

|

Density

|

64kg/m3, 96kg/m3, 128kg/m3

|

|

Size

|

15000*610/1220*10mm

14400/14640*610/1220*12.5mm 7200/7320*610/1220*20mm 7200/7320*610/1220*25mm 5000*610/1220*30mm 4500*640/1220*25mm

3600/3660*610/1220*50mm

Blanket size can be customized.

|

|

Package

|

1.Plastic coated woven bag

2.inner plastic bag, outside carton box

3.inner plastic bag, outside carton box, then packed on pallets

|

|

Payment

|

T/T,L/C,D/A,D/P,Western Union,MoneyGram

30% deposits, 70% balance before delivery

Payment method can be negotiated. |

|

MOQ

|

1 roll

|

|

Sample

|

We supply small samples for free !

|

Typical Parameters

|

Description

|

LUYANGWOOL®

STD BLANKET |

|

|

LUYANGWOOL®

HP BLANKET |

|

LUYANGWOOL®

HA BLANKET |

|

LUYANGWOOL®

HZ BLANKET |

|

|||||||||

|

Classification Temperature (℃ )

|

1260

|

|

|

1260

|

|

1350

|

|

1430

|

|

|||||||||

|

Chemical Composition (%)

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Al2O3

|

≥43

|

|

|

≥44

|

|

≥52

|

|

≥35

|

|

|||||||||

|

SiO2

|

≥54

|

|

|

≥55

|

|

≥47

|

|

≥49

|

|

|||||||||

|

ZrO2

|

-

|

|

|

-

|

|

-

|

|

≥15

|

|

|||||||||

|

Color

|

White

|

|

|

White

|

|

White

|

|

White

|

|

|||||||||

|

Shot Content (%)

|

≤15

|

|

|

≤15

|

|

≤15

|

|

≤12

|

|

|||||||||

|

Density (kg/m³)

|

64

|

96

|

128

|

96

|

128

|

96

|

128

|

96

|

128

|

|||||||||

|

Tensile Strength (kPa)

|

30

|

50

|

70

|

50

|

70

|

50

|

70

|

50

|

70

|

|||||||||

|

Permanent Linear Shrinkage (%)

|

1000℃ x 24h ≤2.5

|

|

|

1100℃ x 24h ≤2.5

|

|

1200℃ x 24h ≤3.0

|

|

1350℃ x 24h ≤3.0

|

|

|||||||||

|

Thermal Conductivity (W/m·K)

|

|

|

|

|

|

|

|

|

|

|||||||||

|

200℃

|

0.07

|

0.06

|

0.06

|

0.06

|

0.06

|

0.06

|

0.06

|

0.06

|

0.06

|

|||||||||

|

400℃

|

0.12

|

0.11

|

0.10

|

0.11

|

0.10

|

0.11

|

0.10

|

0.11

|

0.10

|

|||||||||

|

600℃

|

0.20

|

0.19

|

0.18

|

0.19

|

0.17

|

0.18

|

0.16

|

0.16

|

0.15

|

|||||||||

|

800℃

|

0.30

|

0.23

|

0.20

|

0.23

|

0.20

|

0.22

|

0.20

|

0.21

|

0.19

|

|||||||||

|

1000℃

|

0.40

|

0.32

|

0.27

|

0.31

|

0.26

|

0.30

|

0.26

|

0.30

|

0.26

|

|||||||||

Application

Typical Applications

Furnace and kiln back-up insulation

Chimney insulation

Annealing furnace linings

Process heater linings

Hot Searches