- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

KITECH

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

2300*2000*2600mm

-

Power (kW):

-

55

-

Weight (T):

-

5

-

Keywords:

-

plastic shredder

-

Raw material:

-

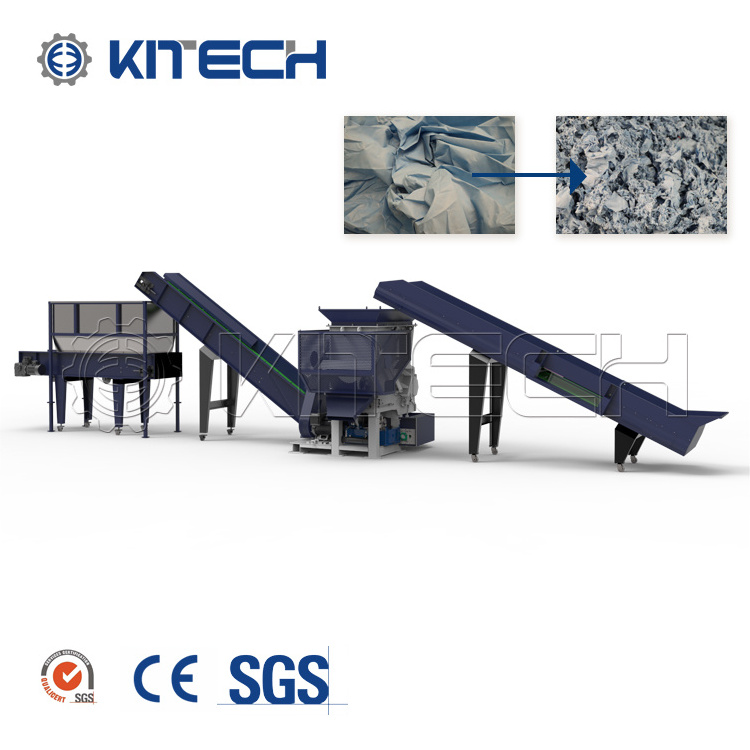

Waste Plastic Film,soft plastic, waste plastic bag

-

Output Product:

-

Plastic scraps,flakes

-

Material Processed:

-

shredding

-

Shaft Diameter:

-

850-2000mm

-

Motor:

-

Marathon/WEG

-

Product name:

-

Plastic And Tire Recycling Heavy Duty Shredder

-

Capacity:

-

300-2000kg/h

-

Shaft type:

-

Single

-

After-sales Service Provided:

-

Field installation, commissioning and training

Quick Details

-

Max.Production Capacity (kg/h):

-

2000

-

Place of Origin:

-

Jiangsu, China

-

Production Capacity (kg/h):

-

300 - 2000 kg/h

-

Brand Name:

-

KITECH

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

2300*2000*2600mm

-

Power (kW):

-

55

-

Weight (T):

-

5

-

Keywords:

-

plastic shredder

-

Raw material:

-

Waste Plastic Film,soft plastic, waste plastic bag

-

Output Product:

-

Plastic scraps,flakes

-

Material Processed:

-

shredding

-

Shaft Diameter:

-

850-2000mm

-

Motor:

-

Marathon/WEG

-

Product name:

-

Plastic And Tire Recycling Heavy Duty Shredder

-

Capacity:

-

300-2000kg/h

-

Shaft type:

-

Single

-

After-sales Service Provided:

-

Field installation, commissioning and training

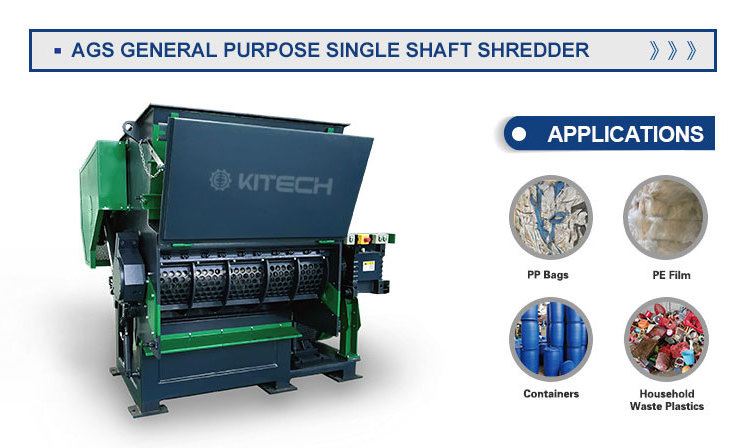

Plastic And Tire Recycling Single Shaft Shredder

The AGS General Purpose Single Shaft Shredder has a 457mm diameter profiled rotor made of solid steel, operating at a speed of 74rpm. The concave ground,aggressive 4-way rotating knives are mounted in the grooves of the profiled rotor with special knife holders. This enables a reduction of the cutting gap between the counter knives and the rotor which guarantees a high flow rate,low power consumption and maximum output of shredded material.

Welcome To KiTech

Products Description

GENERALDESCRIPTION >>

>>

The hydraulically operated ram feeds the material automatically in the rotor's cutting chamber by load-related controls. The hydraulic system is equipped with high-pressure valves and volumetric flow controls which can be set according to the requirements of the input material.

>>

Extremely robust pedestal bearing housings are mounted outside the machine and separate to the cutting chamber to prevent dust and dirt penetrating into the oversized

bearings. This ensures a long service life and minimum service and maintenance.

>>

Power is transmitted from the motor by a drive belt via an oversized gearbox which is located on the shaft end on one end of the rotor.

>>A safety switch prevents machine startup when the front panel is open and the machine features emergency stop buttons on the machine body and control panel.

KEY FEATURES >>

>>

Large diameter flat rotor

>>

Machined pocket knife holders

>>

Optional hard facing

>>

Concave ground square knives

>>

Robust ram construction

>>

Heavy duty guide bearings

>>

Universal couplings

>>

Low speed, high torque geared drive

>>

Reduced footprint - (compared to

horizontal pusher designs)

>>

Powerful hydraulic swing type ram

>>

Bolt in drive shafts

>>

Oil coaling on ram and gearbox

>>

Two speed hydraulic system

>>

Multiple rotor designs

>>

Ram comb plate

>>

Amp meter control

OPTIONS >>

>>

ydraulic screen cradle

>>

Gearbox with shrink disc

>>

Rotor cooling

>>

Pipe spacer

>>

Touch screen PLC

>>

Hopper mounted viewing mirror

>>

Increased motor drive

>>

Hydraulic drive

Technology Data

|

ITEM

|

|

UNIT

|

AGS850

|

AGS1200

|

AGS1500

|

AGS2000

|

|

|

Cutting Chamber

|

|

mm

|

840X1570

|

1120X1570

|

1400X1570

|

1960X1570

|

|

|

Rotor Diameter

|

|

mm

|

457

|

457

|

457

|

457

|

|

|

Rotor Speed

|

|

rpm

|

74

|

74

|

74

|

74

|

|

|

Motor Power

|

|

kw

|

37/45/55

|

55

|

75

|

2X55/2X75

|

|

|

Rotor Knives

|

|

pcs

|

60

|

81

|

102

|

144

|

|

|

Stator Knives

|

|

pcs

|

2X3

|

2X4

|

2X5

|

2X7

|

|

|

Hydraulic Ram Power

|

|

kw

|

3.75

|

5.6

|

5.6

|

5.6

|

|

|

Screen Size

|

|

mm

|

40-100

|

40-100

|

40-100

|

40-100

|

|

|

Shredding Chamber Size

|

|

mm

|

800X730

|

800X1000

|

800X1290

|

800X1860

|

|

|

Dimensions

|

A

|

mm

|

2300

|

2300

|

2300

|

2300

|

|

|

|

B

|

mm

|

1650

|

1650

|

1650

|

1650

|

|

|

|

C

|

mm

|

540

|

540

|

540

|

540

|

|

|

|

D

|

mm

|

660

|

660

|

660

|

660

|

|

|

|

E

|

mm

|

2250

|

2250

|

2250

|

2250

|

|

|

|

F

|

mm

|

350

|

350

|

350

|

350

|

|

|

|

G

|

mm

|

2000

|

2280

|

2600

|

3720

|

|

Recommend Products

Successful Project

Our Company

Hot Searches