- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

0.5%

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LIENM

-

Dimension(L*W*H):

-

contact us

-

Weight:

-

500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Inner Heating Type Tube Filling Sealing Machine

-

Capacity:

-

30-80 tubes/min

-

Tube diameter:

-

10-55mm

-

Filling volume:

-

2-250ml

-

Tube lenth:

-

50-220mm

-

Usage:

-

Ointment, cream, gel and viscosity fluid,etc.

-

Heating mode:

-

Inner Heating

-

Market:

-

Africa, Asia, Australia, Europe,USA,etc

-

Marketing Type:

-

Hot Product

Quick Details

-

Machinery Capacity:

-

4000BPH, 6000BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Wood

-

Filling Material:

-

Other, Cosmetic creams

-

Filling Accuracy:

-

0.5%

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LIENM

-

Dimension(L*W*H):

-

contact us

-

Weight:

-

500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Inner Heating Type Tube Filling Sealing Machine

-

Capacity:

-

30-80 tubes/min

-

Tube diameter:

-

10-55mm

-

Filling volume:

-

2-250ml

-

Tube lenth:

-

50-220mm

-

Usage:

-

Ointment, cream, gel and viscosity fluid,etc.

-

Heating mode:

-

Inner Heating

-

Market:

-

Africa, Asia, Australia, Europe,USA,etc

-

Marketing Type:

-

Hot Product

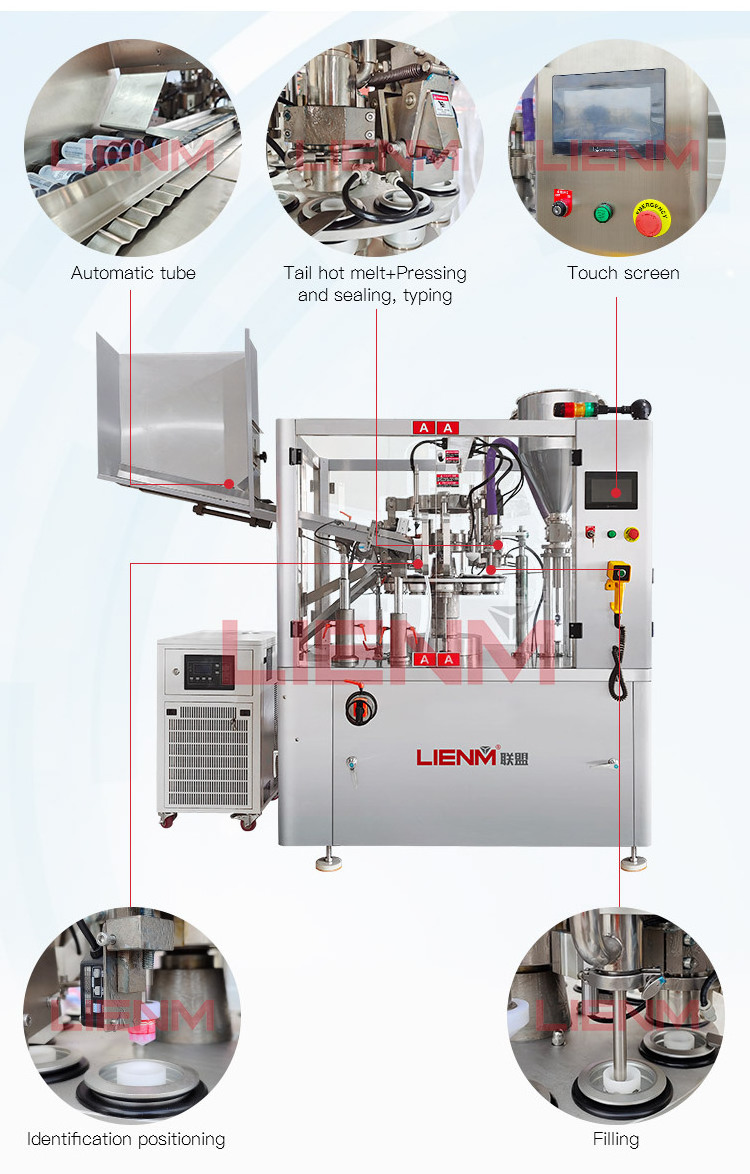

Product Description

Equipment scope:

Cosmetics, light industry (daily chemical), food and other industries, used for enterprise products to choose the hose as the packaging container, the equipment can fill the ointment, cream, gel or viscosity fluid and other materials inside the hose, and then the hose tail of the hot melt press combined printing code, while trimming and shaping, to produce the finished product.

Cosmetics, light industry (daily chemical), food and other industries, used for enterprise products to choose the hose as the packaging container, the equipment can fill the ointment, cream, gel or viscosity fluid and other materials inside the hose, and then the hose tail of the hot melt press combined printing code, while trimming and shaping, to produce the finished product.

Packaging and filling materials applicable scope:

1) Plastic pipe, plastic composite pipe, aluminum-plastic composite pipe.

2) Ointments, creams, gels and viscosity fluids

Work flow:

Work flow:

Pipe silo (hose container) → automatic loading → Calibration → internal cleaning of hose (option) → filling → hot melt

of tail → pressing and sealing, coding → hose positioning → cutting → finished product discharge

of tail → pressing and sealing, coding → hose positioning → cutting → finished product discharge

How it works:

PLC program control. Automatic tube loading, color calibration, air cleaning of the inner tube space, filling of the injector into the tube, heating of the inner wall of the tube tail, cooling of the outer wall of the tube tail (drainage cycle of the refrigeration machine), hot melt pressing and typing, tail shear, finished product discharge. Parameter digital display.

Features:

Features:

◆The host adopts frequency conversion speed regulation.

◆ On the same machine, two-tailed, three-folded or saddle-shaped tails can be realized by different adjustments.

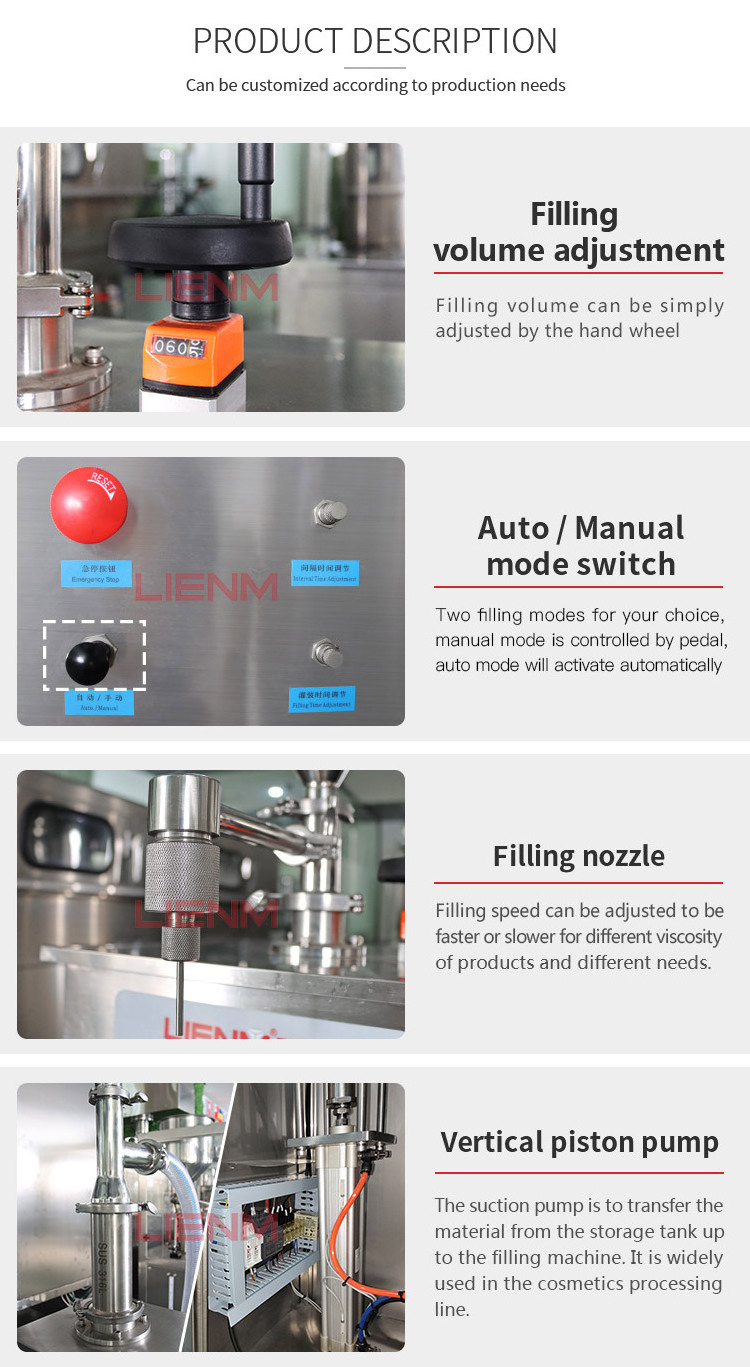

◆The manipulator seal is flexible and stable. The filling and sealing parts are designed to be open, which is very convenient for cleaning and maintenance.

◆Color mark positioning, select German photoelectric identification device, and equipped with high-precision driver and stepper motor (very high benchmarking requirements to configure the feeding motor) to ensure the correct position of the graphic.

◆The injection nozzle is filled into the inner part of the hose, and there is a filling process from bottom to top to complete the filling and sealing, no leakage or overflow. The machine is suitable for filling requirements of various physical and chemical properties. The fine-tuning handwheel is placed outside the body, and the adjustment and tightening are very convenient, ensuring the filling accuracy ≤±0.5%, real cost saving and accurate measurement.

◆The internal mixing of the material barrel is designed as a lower power stirring device, which is safe, reliable and has a wide application range. The barrel insulation system is completed by a controllable water temperature device and a sandwich hopper having a weld-free flux. (option)

◆The terminal compressed air adopts multi-stage filtration (oil and gas filter device to ensure clean air and no pollution). ◆The lubrication system formulates uniform oil supply standards to ensure effective lubrication of the equipment and prevent work environment pollution.

|

Main technical parameters

|

|

|

|

hose material

|

metal tube

|

|

|

Filling range

|

5ml-200ml/piece (adjustable)

|

|

|

Filling accuracy

|

≤±1%

|

|

|

operating speed

|

30-40 / min

|

|

|

hose diameter

|

Φ13-Φ35mm

|

|

|

hose length

|

200mm

|

|

|

200mm

|

380V (optional)

|

|

|

working pressure

|

0.55-0.65Mpa

|

|

|

matching motor

|

1.5kw

|

|

|

Dimensions

|

1500 × 1000 × 2000mm

|

|

|

Machine weight

|

800kg

|

|

Other Types

Recommend Products

Hot Searches