- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Width:

-

MAX:3000mm

-

Ti (Min):

-

99.6%

-

Brand Name:

-

MEIDE

-

Model Number:

-

TC1 TC2 TC3 R56540

-

Product Name:

-

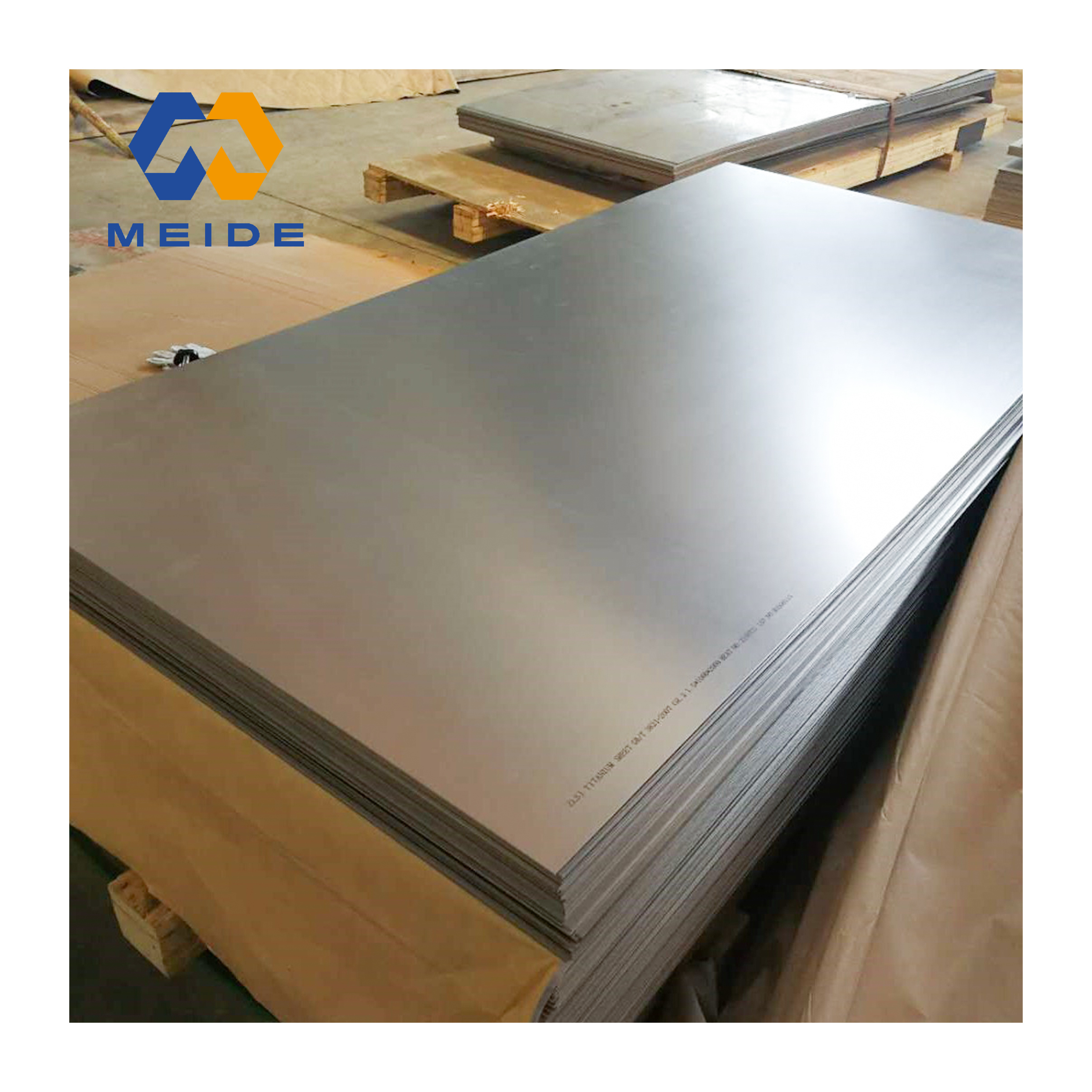

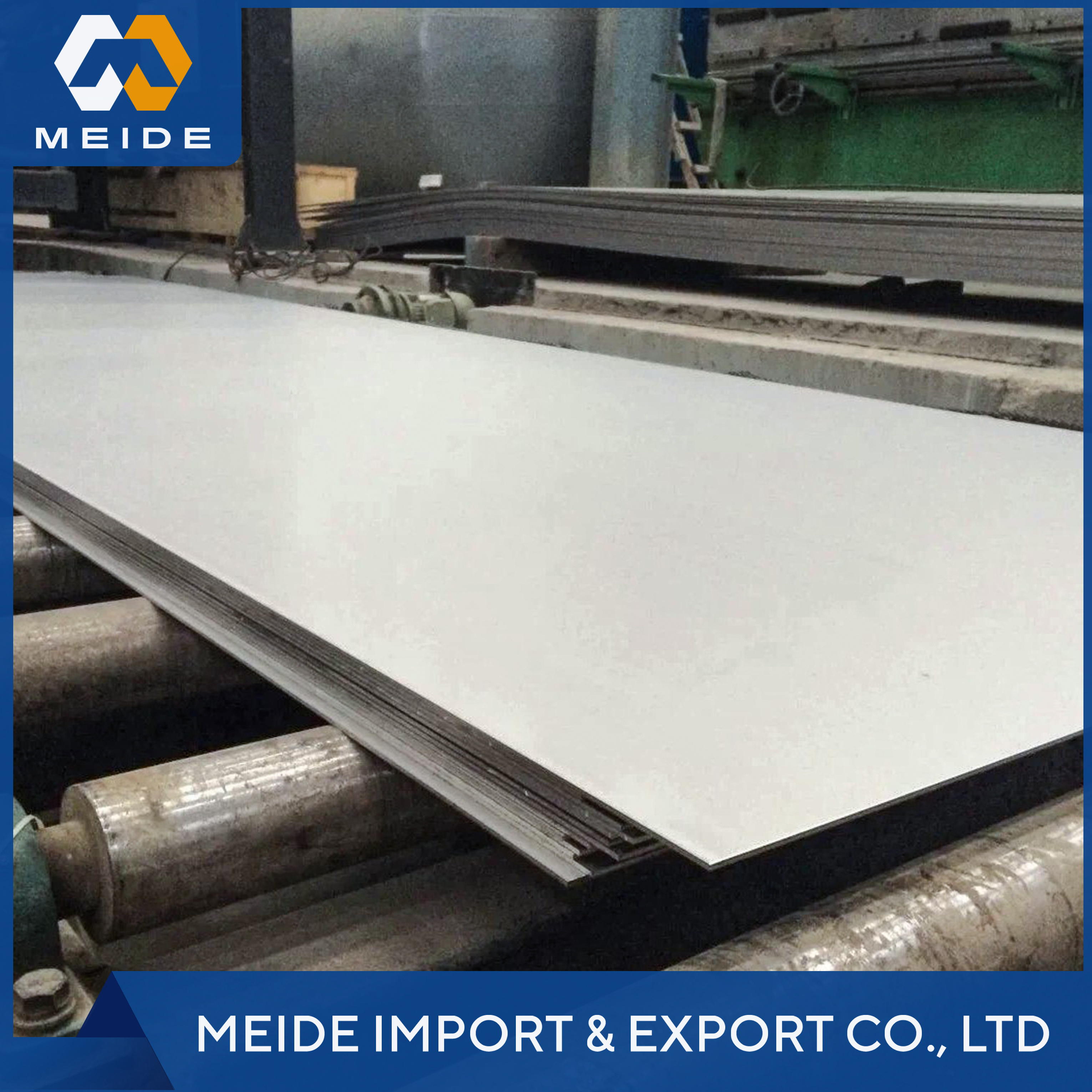

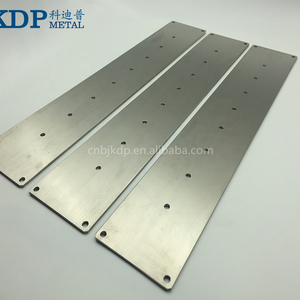

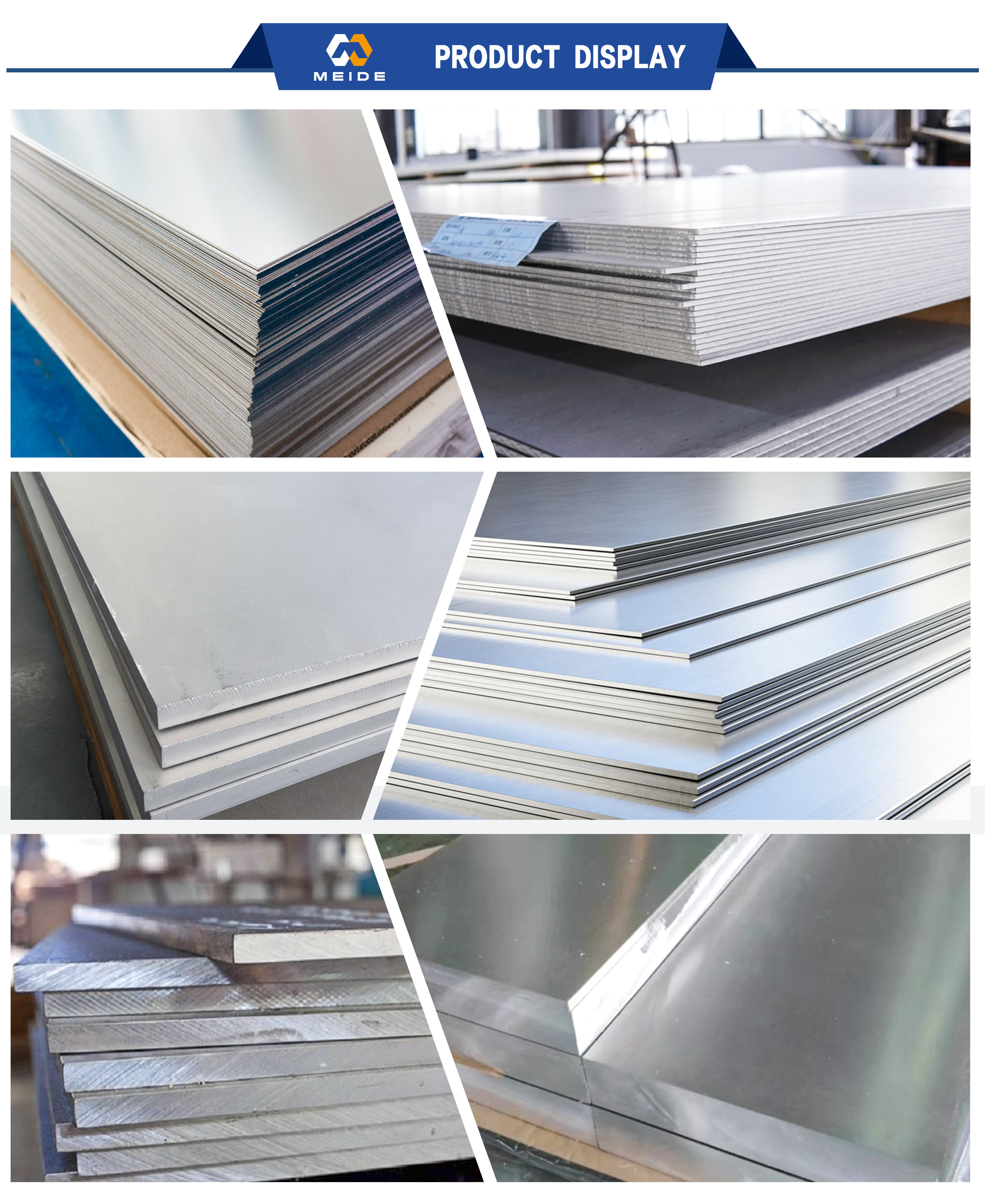

Titanium Alloy Plate sheet

-

Keyword:

-

Titanium Plate sheet

-

MOQ:

-

1kg

-

Material:

-

Titanium GR1/GR2/GR3/GR5/GR7/GR9/GR12/GR13/GR14

-

Shape:

-

Square Flat Sheet Plate Rectangular

-

Type:

-

Titanium Plate Titanium Prices

-

Standard:

-

ASTM B265 SB265 ASTM F67 F136

-

Surface:

-

Polished

-

Advantage:

-

High Strength

Quick Details

-

Application:

-

Industry,medical

-

Length:

-

≤6000mm

-

Technique:

-

Cold Rolled

-

Place of Origin:

-

Shandong, China

-

Width:

-

MAX:3000mm

-

Ti (Min):

-

99.6%

-

Brand Name:

-

MEIDE

-

Model Number:

-

TC1 TC2 TC3 R56540

-

Product Name:

-

Titanium Alloy Plate sheet

-

Keyword:

-

Titanium Plate sheet

-

MOQ:

-

1kg

-

Material:

-

Titanium GR1/GR2/GR3/GR5/GR7/GR9/GR12/GR13/GR14

-

Shape:

-

Square Flat Sheet Plate Rectangular

-

Type:

-

Titanium Plate Titanium Prices

-

Standard:

-

ASTM B265 SB265 ASTM F67 F136

-

Surface:

-

Polished

-

Advantage:

-

High Strength

Product Introduction

The density of titanium is 4.506-4.516g/cm^3, melting point is 1668, boiling point is 3535. Therefore Titanium have low weight, excellent high strength and nonmagnetic festures, low density, excellent corrosion resistance features, high specificate strength and high temperature resistance features, so it is widely used in chemical industry field, medical field, electronics manufacture, mechanical parts field, automobile industry, and aerospace field, etc.

|

Grade

|

TA1, TA2, TA3, TA4, TA10, TA15, TA17, GR1, GR2, GR3, GR4, GR5, GR7, GR9,

GR11, GR12 |

|

Size

|

T (0.6mm - 2.0mm) * W (1000mm) * L (3000mm max)T (3.0mm- 5.0mm)*W

(1250mm)* L (3500mm max) T (6.0mm - 60mm) * W (2500mm max)* L (7000mm max) |

|

Standard

|

ASTM B265, ASTM SB265, AMS 491 ,ASTM F136

|

|

Application

|

Chemical, industry, sports etc.

|

|

Feature

|

High corrosion resistance, low density, good thermal stability

|

|

Surface

|

Bright, Polished, Pickling, Acid cleaning, Sandblasting

|

|

Quality and test

|

Hardness test, Bending test, Hydrostatic etc.

|

|

Finish

|

Roll-up(Hard)

|

|

Surface

|

Polished

|

Grade and Chemical Composition (%) :

|

Grade

|

N(≤)

|

C(≤)

|

H(≤)

|

Fe(≤)

|

O(≤)

|

Al(≤)

|

V(≤)

|

Ni(≤)

|

Ti

|

|

GR1

|

0.03

|

0.08

|

0.015

|

0.2

|

0.18

|

/

|

/

|

/

|

bal

|

|

GR2

|

0.03

|

0.08

|

0.015

|

0.3

|

0.25

|

/

|

/

|

/

|

bal

|

|

GR3

|

0.05

|

0.08

|

0.015

|

0.3

|

0.35

|

/

|

/

|

/

|

bal

|

|

GR4

|

0.05

|

0.08

|

0.015

|

0.2

|

0.4

|

/

|

/

|

/

|

bal

|

|

GR5

|

0.05

|

0.08

|

0.015

|

0.4

|

0.2

|

5.5~6.75

|

3.5~4.5

|

/

|

bal

|

|

GR7

|

0.03

|

0.08

|

0.015

|

0.3

|

0.25

|

/

|

/

|

/

|

bal

|

|

GR9

|

0.03

|

0.08

|

0.015

|

0.25

|

0.15

|

2.5~3.5

|

2.0~3.0

|

/

|

bal

|

|

GR12

|

0.03

|

0.08

|

0.015

|

0.3

|

0.25

|

/

|

/

|

0.6~0.9

|

bal

|

|

GR23

|

0.05

|

0.08

|

0.012

|

0.25

|

0.13

|

5.5~6.5

|

3.5~4.5

|

|

bal

|

Mechanical property

|

Grade

|

Tensil strength(≥)

|

|

Yeild strength(≥))

|

|

Elongation(≥)%)

|

||

|

|

ksi

|

Mpa

|

ksi

|

Mpa

|

|

||

|

GR1

|

35

|

240

|

20

|

138

|

24

|

||

|

GR2

|

50

|

345

|

40

|

275

|

20

|

||

|

GR3

|

65

|

450

|

55

|

380

|

18

|

||

|

GR4

|

80

|

550

|

70

|

483

|

15

|

||

|

GR5

|

130

|

895

|

120

|

828

|

10

|

||

|

GR7

|

50

|

345

|

40

|

275

|

20

|

||

|

GR9

|

90

|

620

|

70

|

483

|

15

|

||

|

GR12

|

70

|

483

|

20

|

345

|

18

|

||

|

GR23

|

120

|

828

|

110

|

760

|

10

|

||

Our Advantages

We can produce all types of sheet piles,pipe piles and accessories,we can adjust our machines to produce in any width x height x thickness .

We can produce single length up to over 100m,and we can do all painting,cutting,welding etc fabrications in factory .

Fully internationally certified:ISO9001,ISO14001,ISO18001,CE,SGS,BV etc..

Product testing

According to globally recognized standards, such as ASTM, AMS, ASME and provide third-party inspection reports, DNV accredited IOS 9001:2008 quality management system

100% titanium sponge to produce titanium ingot and 3 times melting to ensure the uniformity of chemical composition. For chemical composition inspection, not only inspect the titanium ingot, but also the semi finished products and finished products, just to ensure 100% qualified products before shipping.

Mechanical property testing making sure all titanium products can satisfy mechanical features before delivery.

Strict inspection when producing and finished products. Visual inspection to check surface quality, ensuring without flaw, black dot and any other defects.

Ultrasonic Flaw Detection make sure they are no defect inside.

Chemical Composition detection make sure all chemical component can meet your demands.

Yield strength, tensile strength, elongation percentage reduction of area, Impact bending test, microstructure tests.

Hardness testing, Penetrant testing, Radiographic testing etc. as per your requirements.

Product application

Petroleum, Metallurgy, Chemical, Pharmacy, Marine Engineering, Racing Car, Motorcycle, Bicycle, Yacht, Outdoor Camping and Sports Equipment. Medical industry, aerospace, spaceflight, airplane, military,etc

FAQ

1.Are you a manufacturer or a trader?

We're a manufacturer with more than years of professional production experience.

2.Can you accept OEM?

Yes, OEM is acceptable. Just pls provide us with the drawing or sample, we will production totally according to your requirements.

3.Can you provide us with the design drawing?

Yeah, of course, we will provide you with the drawing after you paid or prepaid.

4.Can your factory produce products according to our drawings?

Yes, we can. Most products can be customized, including the Logo on products.

5.What kind of your packaging?

Neutral plywood or wooden box packaging or according to customer's requirements.

6.How long is your delivery time?

Normally 30days after payment, and we promise we will deliver as soon as we can.

7.How can we get your price ?

1. We need below information to quote for you:

1). Product Name

2). Standard

3). Material Grade (Chemical Composition)

4). Dimension

5). Quantity

6). The Drawing for Special Parts

We're a manufacturer with more than years of professional production experience.

2.Can you accept OEM?

Yes, OEM is acceptable. Just pls provide us with the drawing or sample, we will production totally according to your requirements.

3.Can you provide us with the design drawing?

Yeah, of course, we will provide you with the drawing after you paid or prepaid.

4.Can your factory produce products according to our drawings?

Yes, we can. Most products can be customized, including the Logo on products.

5.What kind of your packaging?

Neutral plywood or wooden box packaging or according to customer's requirements.

6.How long is your delivery time?

Normally 30days after payment, and we promise we will deliver as soon as we can.

7.How can we get your price ?

1. We need below information to quote for you:

1). Product Name

2). Standard

3). Material Grade (Chemical Composition)

4). Dimension

5). Quantity

6). The Drawing for Special Parts

Hot Searches