- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Power:

-

3kw

-

Weight:

-

7000 KG

-

Dimension(L*W*H):

-

9*0.8*1.85m

-

Product name:

-

Sugar Cone Making Machine Rolled Ice Cream Cone Production Line

-

Feature:

-

High Efficiency Easy Operation

Quick Details

-

Marketing Type:

-

Hot Product

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Gelgoog

-

Voltage:

-

380v

-

Power:

-

3kw

-

Weight:

-

7000 KG

-

Dimension(L*W*H):

-

9*0.8*1.85m

-

Product name:

-

Sugar Cone Making Machine Rolled Ice Cream Cone Production Line

-

Feature:

-

High Efficiency Easy Operation

Product Details

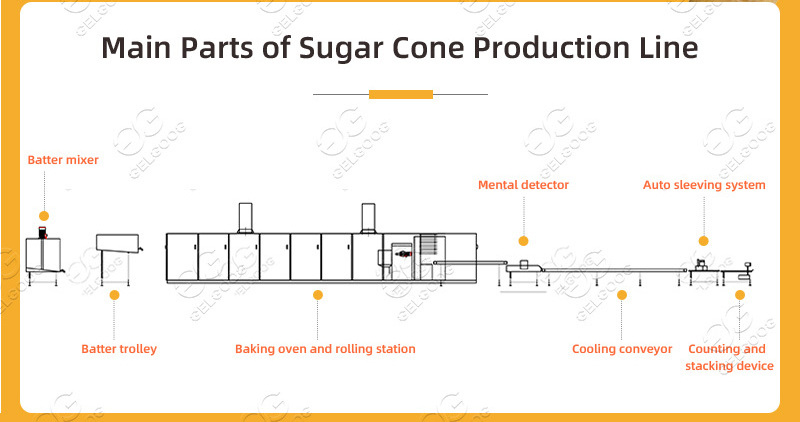

Ice Cream Cone Production Line

Full automatic ice cream cone production line to make ice cream sugar cone with high quality. This sugar cone production line can make sugar rolled cone, waffle cone and bowl-shaped waffle cup. We can design the different model of ice cream processing solution to make different types of sugar-rolled cones as required by clients.

Technical Data

|

Model

|

Voltage

|

Power

|

Capacity

|

Air consumption

|

Power consumption

|

Baking Pan Size

|

Size

|

Weight

|

|

GG-DCL35

|

380v 50hz

|

3kw

|

1500-2000pcs/h

|

6-8m³/h

|

3kw/h

|

260mm

|

6*0.8*1.85m

|

6T

|

|

GG-DCL37

|

380v 50hz

|

3kw

|

3500-4000pcs/h

|

6-8m³/h

|

3kw/h

|

260mm

|

7*0.8*1.85m

|

6T

|

|

GG-DCL45

|

380v 50hz

|

3kw

|

4000-5000pcs/h

|

6-8m³/h

|

3kw/h

|

260mm

|

8*0.8*1.85m

|

6T

|

|

GG-DCL55

|

380v 50hz

|

3kw

|

6000-7000pcs/h

|

6-8m³/h

|

3kw/h

|

260mm

|

9*0.8*1.85m

|

7T

|

|

GG-DCL65

|

380v 50hz

|

3kw

|

7000-8000pcs/h

|

6-8m³/h

|

3kw/h

|

260mm

|

12*0.8*1.85m

|

8T

|

|

GG-DCL75

|

380v 50hz

|

3kw

|

12000-15000pcs/h

|

8-10m³/h

|

3kw/h

|

260mm

|

11*1.9*1.85m

|

7T

|

Important reminder:

1,The technical parameters are for reference only.

2,The product quotation is for reference only, It is based on the actual purchased model and configuration.

3,For more information, please call or consult customer service.

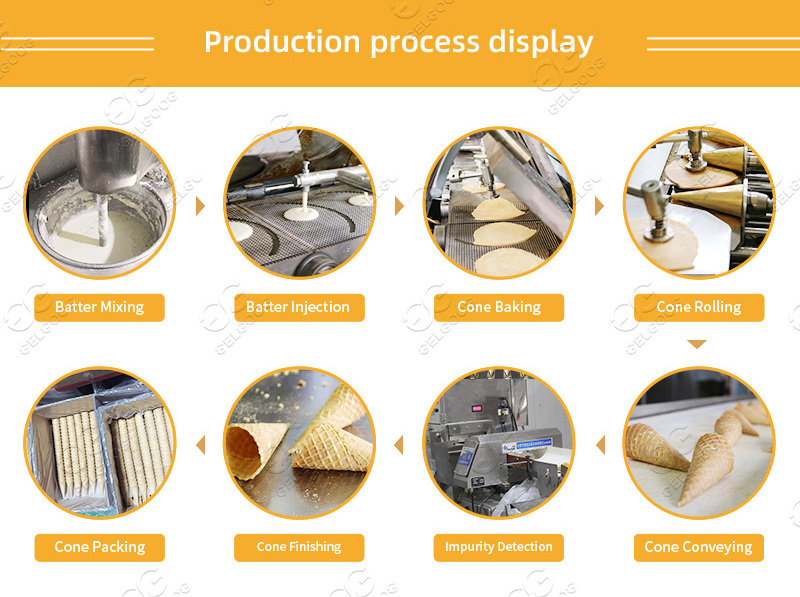

Processing Flow

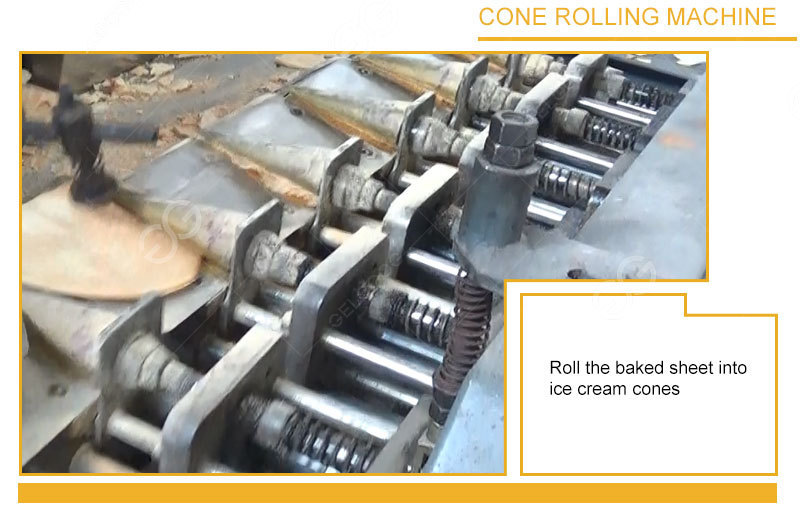

Working Principle of Sugar Cone Making Machine

The mixed flour paste is fed to the baking plant by feeding pump and close the plate,adjust the temperature, put it into the

oven.After baking, it is transported to the mould of rolling. Finally, the finished product falls from the discharge hole.

oven.After baking, it is transported to the mould of rolling. Finally, the finished product falls from the discharge hole.

Detailed Images

Related Product

Hot Searches