- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Z) (mm):

-

60 mm

-

Max. Table Load(kg):

-

OTHER

-

Travel (W-axis) (mm):

-

50 mm

-

Positioning Accuracy (X axis) mm:

-

1

-

Positioning Accuracy (Y axis) mm:

-

1

-

Positioning Accuracy (Z axis) mm:

-

1

-

Range of Spindle Speed(r.p.m):

-

200 r.p.m

-

Spindle Motor Power(kW):

-

2.5

-

Production Capacity:

-

OTHER

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

HG

-

Voltage:

-

220v, 220V

-

Dimension(L*W*H):

-

400*210*290mm

-

Weight (T):

-

0.09 T

-

Product name:

-

Portable Line Boring Machine Line Bore Welder

-

Model:

-

HG-45

-

Scope diameter:

-

40-250mm

-

Boring working stroke:

-

280mm

-

Boring bar specification:

-

50*1600mm

-

Working voltage:

-

AC220v/50hz

-

Welding scope:

-

45-250mm

-

Application:

-

Crawler excavator

-

Weight:

-

90kg

Quick Details

-

Table Size (mm):

-

260mm

-

Table Travel (X) (mm):

-

50 mm

-

Table Travel (Y) (mm):

-

40 mm

-

Table Travel (Z) (mm):

-

60 mm

-

Max. Table Load(kg):

-

OTHER

-

Travel (W-axis) (mm):

-

50 mm

-

Positioning Accuracy (X axis) mm:

-

1

-

Positioning Accuracy (Y axis) mm:

-

1

-

Positioning Accuracy (Z axis) mm:

-

1

-

Range of Spindle Speed(r.p.m):

-

200 r.p.m

-

Spindle Motor Power(kW):

-

2.5

-

Production Capacity:

-

OTHER

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

HG

-

Voltage:

-

220v, 220V

-

Dimension(L*W*H):

-

400*210*290mm

-

Weight (T):

-

0.09 T

-

Product name:

-

Portable Line Boring Machine Line Bore Welder

-

Model:

-

HG-45

-

Scope diameter:

-

40-250mm

-

Boring working stroke:

-

280mm

-

Boring bar specification:

-

50*1600mm

-

Working voltage:

-

AC220v/50hz

-

Welding scope:

-

45-250mm

-

Application:

-

Crawler excavator

-

Weight:

-

90kg

Product Description

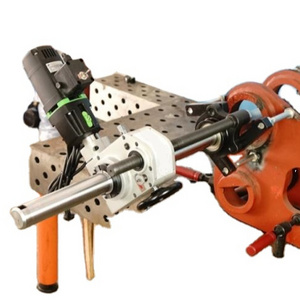

HG-45 Portable Line Boring Machine Line Bore Welder Repairing Excavator

Portable Line Boring Machine Line Bore Welder Repairing Excavator

is very convenient and specially designed for on-site machining, it is featured with small volume, light weight, easy bringing and high quality welding. It can be widely used to weld and repair the hole of large-sized machinery, pivot pin hole of earth moving equipment and bearing hole. It is ideal and necessary equipment for the industry and mining enterprise and on-site engineering repairing.

Technical parameters

|

Product name

|

Portable Line Boring Machine Line Bore Welder Repairing Excavator

|

|

Scope

|

Φ 40-200 - mm

|

|

Boring working stroke

|

260mm

|

|

Boring bar specification

|

50*1600mm

|

|

Working voltage

|

AC 220v/50hz

|

|

Maximum power

|

2.5kw (electrodeless speed regulation)

|

|

Spindle speed

|

0.1-200r/min

|

|

Welding scope

|

Φ 55-250mm

|

|

Wire diameter

|

Φ 1.0

|

|

Machine weight

|

80KG

|

Features

Portable Line Boring Machine Line Bore Welder Repairing Excavator

1,Main Driving Unit

This series adopts the servo motor driven with the feature of lower speed and higher torque. The gear unit of reduction equipped with machine ensures the more powerful cutting.

2, This new type of 2 in 1 borer and welder solves the problem of distortion of boring bar and vibration during cutting process which are caused by the longer cantilever. Also ensure there is no vibration during the process of axial moving and cutting process.

3, Feeding and spindle rotation adopts stepless speed adjustment, the travel of feeding can be set according to actual

requirement. The machine will stop automatically after reaching the limit stop.

4,The tool post can be fixed at any location within effective travel.

5,Just one equipment solves both boring and welding processing.

6, Separate electric cabinet equipped with the controller, convenient for remote operation, convenient and safe.

7, This machine can be equipped with end face milling attachment as request.

This series adopts the servo motor driven with the feature of lower speed and higher torque. The gear unit of reduction equipped with machine ensures the more powerful cutting.

2, This new type of 2 in 1 borer and welder solves the problem of distortion of boring bar and vibration during cutting process which are caused by the longer cantilever. Also ensure there is no vibration during the process of axial moving and cutting process.

3, Feeding and spindle rotation adopts stepless speed adjustment, the travel of feeding can be set according to actual

requirement. The machine will stop automatically after reaching the limit stop.

4,The tool post can be fixed at any location within effective travel.

5,Just one equipment solves both boring and welding processing.

6, Separate electric cabinet equipped with the controller, convenient for remote operation, convenient and safe.

7, This machine can be equipped with end face milling attachment as request.

Packing&Shipping

Packing: Standard export wooden case for

Portable Line Boring Machine Line Bore Welder Repairing Excavator

Leading time: according your order quantity

Hot Searches