- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SHARE

-

Voltage:

-

220v/380v

-

Dimension(L*W*H):

-

1100*800*1150mm

-

Marketing Type:

-

New Product 2022

-

Weight (KG):

-

200 kg

-

Name:

-

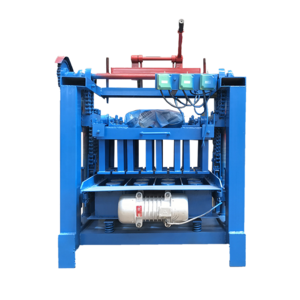

Concrete hollow blocks Building Block machine Brick making machine

-

Keywords:

-

Cement brick making machine

-

Key Words:

-

Brick machine

-

Color:

-

Blue/Yellow

-

Brick shape:

-

Customized

-

Brick Type:

-

Hollow Concrete Brick Machine

-

Weight:

-

200kg

-

Key word:

-

Hollow block machine

-

KW:

-

Paving block making machine

-

Product Name:

-

Block making machine

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Autoclaved aerated concrete block (AAC)

-

Brick Raw Material:

-

CONCRETE

-

Production Capacity (Pieces/8 hours):

-

1000~1200pcs/8hr

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SHARE

-

Voltage:

-

220v/380v

-

Dimension(L*W*H):

-

1100*800*1150mm

-

Marketing Type:

-

New Product 2022

-

Weight (KG):

-

200 kg

-

Name:

-

Concrete hollow blocks Building Block machine Brick making machine

-

Keywords:

-

Cement brick making machine

-

Key Words:

-

Brick machine

-

Color:

-

Blue/Yellow

-

Brick shape:

-

Customized

-

Brick Type:

-

Hollow Concrete Brick Machine

-

Weight:

-

200kg

-

Key word:

-

Hollow block machine

-

KW:

-

Paving block making machine

-

Product Name:

-

Block making machine

Product Description

Concrete Hollow Blocks Building Block Machine Price in the Philippines Brick Making Machine

This small mobile manual Soil cement hollow brick block machine is drived by electric. But manual operate. It's save cost, high efficiency,

flexible and portable

. 1-2 person can operate this machine. Saves labor.Easy learning and easy operate.

Details Images

|

Model

|

SRZJ-XQK

|

Voltage

|

220v or customize as your need

|

||

|

Operation

|

1-2 person

|

Power

|

2.2kw

|

||

|

Moulding Pressure

|

1.5t

|

Capacity

|

1000~1200pcs/8hr

|

||

|

Weight

|

200kg

|

Demension

|

1100*880*1150mm

|

||

|

Normal Brick Size

|

400*200*200mm 3pcs/time

390*390*190mm 3pcs/time 390*150*190mm 3pcs/time 390*150*190mm 3pcs/time 390*120*190mm 4pcs/time 240*115*53mm 12pcs/time

The mold can be widened or raised according to customer's requirement.

|

|

|

||

For the machine. It can work with motors. Also can work with the diesel engine.

This is the machine with motors.

These two machines are the machine with desiel engine, which is more powerful and high efficiency.

For the brick block shape and size. We can customize as your request. The following normal moulds after made for your reference. If you only order one machine, can also add extra moulds, then change the moulds when use.

Machines are in Mass Production. Please feel free to contact with me if you are interested the block machines. We also have other big models brick making machines.

Machines Packing

Features

1.Forming machine frame: using high strength steel and special welding process, extremely strong.

2.Guide column: made of super special steel, the surface of chrome plating with torsion and wear resistance.

3.Brick machine mould head: mechanical and electrical hydraulic synchronous drive, the same plate products height error is very small.

4.Distributing Device: the use of sensing and hydraulic proportional drive technology, in the swing under the action of the cloth cart forced centrifugal discharge, cloth quickly uniform, especially beneficial to multi-row hole products.

5.Cement brick machine vibrator: driven by electro-hydraulic technology, multi-source vibration system, in the computer control by hydraulic drive vertical synchronous vibration, frequency auxiliary adjustable, to achieve the low frequency feeding, hig frequency molding working principle, for different raw materials can obtain the vibration effect.

6.Through the replacement of different molds, the production of different specifications of porous bricks, standard bricks, hollow block, the secondary cloth device can be produced along the stone, color pavement brick, grass brick, slope brick and other products.

2.Guide column: made of super special steel, the surface of chrome plating with torsion and wear resistance.

3.Brick machine mould head: mechanical and electrical hydraulic synchronous drive, the same plate products height error is very small.

4.Distributing Device: the use of sensing and hydraulic proportional drive technology, in the swing under the action of the cloth cart forced centrifugal discharge, cloth quickly uniform, especially beneficial to multi-row hole products.

5.Cement brick machine vibrator: driven by electro-hydraulic technology, multi-source vibration system, in the computer control by hydraulic drive vertical synchronous vibration, frequency auxiliary adjustable, to achieve the low frequency feeding, hig frequency molding working principle, for different raw materials can obtain the vibration effect.

6.Through the replacement of different molds, the production of different specifications of porous bricks, standard bricks, hollow block, the secondary cloth device can be produced along the stone, color pavement brick, grass brick, slope brick and other products.

Packing & Delivery

Our Company

FAQ

My Contact

Sales Manager:Chris

Whatsapp/Wechat/Phone:+86

13223018559

.

Hot Searches