- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ORME

-

Weight:

-

500 KG

-

Dimension(L*W*H):

-

1250*650*2150MM

-

Name:

-

Vertical hydraulic baler

-

Machine type:

-

Hydraulic packer

-

Usage:

-

Fully automatic and manual

-

Control system:

-

Easy to operate

-

Hay balers Application:

-

Completely maintain the physical characteristics of the material

-

Baling track:

-

Two bundles for easy operation

-

Platen:

-

The platen automatically returns to position

-

Compression effect:

-

Anti-rebound barb, keep compression effect

-

Compaction ratio:

-

The waste compaction ratio can reach 5:1

-

Dynamic:

-

High power

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

4KW

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ORME

-

Weight:

-

500 KG

-

Dimension(L*W*H):

-

1250*650*2150MM

-

Name:

-

Vertical hydraulic baler

-

Machine type:

-

Hydraulic packer

-

Usage:

-

Fully automatic and manual

-

Control system:

-

Easy to operate

-

Hay balers Application:

-

Completely maintain the physical characteristics of the material

-

Baling track:

-

Two bundles for easy operation

-

Platen:

-

The platen automatically returns to position

-

Compression effect:

-

Anti-rebound barb, keep compression effect

-

Compaction ratio:

-

The waste compaction ratio can reach 5:1

-

Dynamic:

-

High power

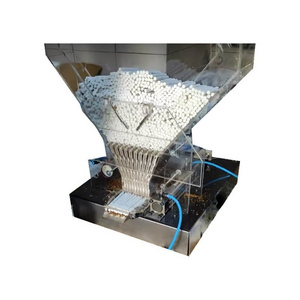

Product Description

Introduction

Vertical hydraulic baler is mainly used for recycling compressed cardboard, waste film,waste paper, foam, beverage cans and industrial scraps and other packaging materials and waste products. This vertical baler reduces waste storage space,saves up to 80% of stacking space, reduces transportation costs, and facilitates environmental protection and waste recycling.

Features

1. Hydraulic compaction, manual loading, manual button operation

2. Completely maintain the physical characteristics of the material

3. The waste compaction ratio can reach 5:1

4. Two bundles for easy operation

5. Anti-rebound barb, keep compression effect

6. The platen automatically returns to position

2. Completely maintain the physical characteristics of the material

3. The waste compaction ratio can reach 5:1

4. Two bundles for easy operation

5. Anti-rebound barb, keep compression effect

6. The platen automatically returns to position

Parameter

|

Model

|

Motor

(kw)

|

Package size

|

Overall

dimensions

|

oil pump

(mm)

|

Cylinder bore

|

Oil cylinder diameter

|

|

8T Single bar

|

4

|

600*400*600

|

1250*650*2150

|

306 Gear Pumps

|

80

|

90

|

|

10T Single bar

|

7.5

|

800*400*800

|

1450*650*2600

|

320 Gear Pumps

|

100

|

115

|

|

20T Single bar

|

7.5

|

800*400*800

|

1450*650*2700

|

325 Gear Pumps

|

125

|

140

|

|

30T Single bar

|

11

|

1000*600*800

|

1650*850*2750

|

532 Gear Pumps

|

140

|

160

|

|

30T Double bar

|

11

|

1000*600*800

|

1650*850*2700

|

532 Gear Pumps

|

100

|

115

|

|

40T Double bar

|

11

|

1000*600*800

|

1650*850*2750

|

550 Gear Pumps

|

125

|

140

|

|

60T Double bar

|

15

|

1200*800*1000

|

1600*2100*3100

|

563 Gear Pumps

|

140

|

160

|

|

80T Double bar

|

18.5

|

1200*800*1000

|

1700*2100*3300

|

563 Gear Pumps

|

160

|

180

|

|

100T Double bar

|

22

|

1200*800*1000

|

1700*2100*3900

|

563 Gear Pumps

|

160

|

180

|

|

120TFull steel plate

|

22

|

1100*700

|

1400*2000*4200

|

80YCY PZS

|

200

|

230

|

Product Photograph

Packing & Shipping

Install waterproof membrane to reduce dust and water pollution.

Standard wooden boxes are used as outer packaging to reduce bumps in international transportation.

Standard wooden boxes are used as outer packaging to reduce bumps in international transportation.

Hot Searches