- Product Details

- {{item.text}}

Quick Details

-

Production Speed(Cycles/min):

-

20

-

Air Pressure(MPa):

-

1 MPa

-

Sheet Thickness(mm):

-

0.2 - 0.6 mm

-

Heating Power (kW):

-

10 kW

-

Air Comsumption(L/min):

-

1 L/min

-

Water Comsumption(L/min):

-

0.5 L/min

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Xinhua

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3800 x 920 x 1750

-

Weight (T):

-

2 T

-

Power(KW):

-

13

-

Weight:

-

1250

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Packaging Material:

-

PVC, PS or PET

-

Working Flows:

-

Forming-Cutting

-

Max Forming Area:

-

450 x 150

-

Control Type:

-

PLC and Touch screen

-

Name:

-

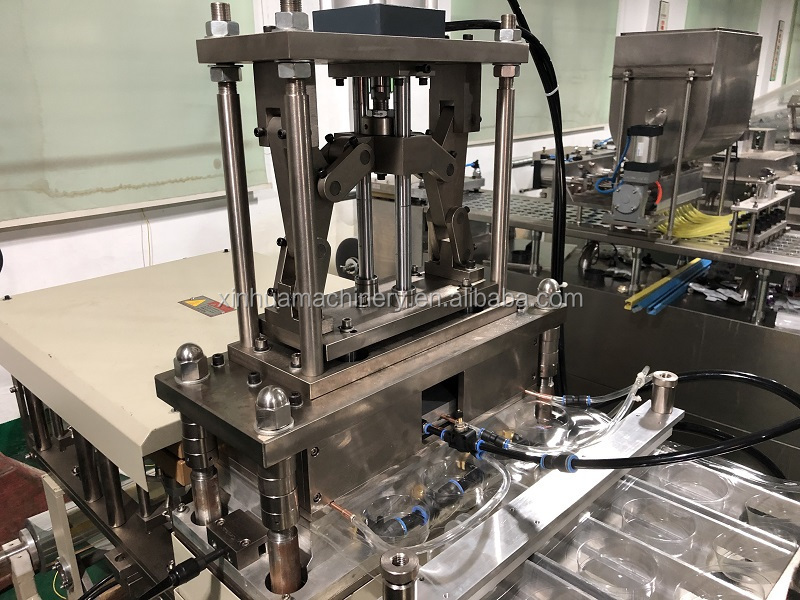

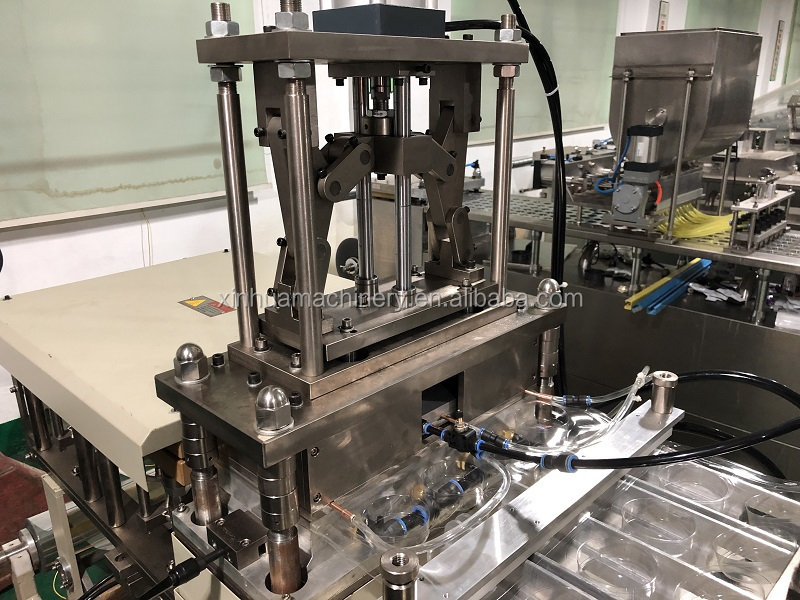

plastic cup lid thermo forming punching machine with low price

-

Power(W):

-

13K

Quick Details

-

Max.Forming Height(mm):

-

50 mm

-

Forming Width (mm):

-

450 mm

-

Forming Length (mm):

-

200 mm

-

Production Speed(Cycles/min):

-

20

-

Air Pressure(MPa):

-

1 MPa

-

Sheet Thickness(mm):

-

0.2 - 0.6 mm

-

Heating Power (kW):

-

10 kW

-

Air Comsumption(L/min):

-

1 L/min

-

Water Comsumption(L/min):

-

0.5 L/min

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Xinhua

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3800 x 920 x 1750

-

Weight (T):

-

2 T

-

Power(KW):

-

13

-

Weight:

-

1250

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Packaging Material:

-

PVC, PS or PET

-

Working Flows:

-

Forming-Cutting

-

Max Forming Area:

-

450 x 150

-

Control Type:

-

PLC and Touch screen

-

Name:

-

plastic cup lid thermo forming punching machine with low price

-

Power(W):

-

13K

Product Application

Best selling plastic cup lid thermo forming punching machine with low price assembles with thermo forming, punching and cutting for plastic cups, trays and other containers, which is very easy to operate and any other containers, which is very easy to operate and less power consumption. The fully automatic working processes are from temperature control-ling thermo forming, punching, cutting, counting and scrapes drawing back.

Sheet material: PVC, PS, PET

What is the Technical Parameter Details of this machine?

| Model |

CQ450 |

| Cutting time | 15-20 times/min |

| Power supply | 380v/220v 50Hz |

| Max forming area(mm x mm) |

450 x 150 |

| Max forming depth |

40mm |

| Heating power for upper forming mould |

5 Kw |

| Heating power for lower forming mould |

5 Kw |

| Motor Power | 3 Kw |

| Air pump pressure | 0.7 Mpa |

| Air supply |

≥0.7m³/min |

| Water Consumption |

0.4m3/h |

| Sheet (thickness X width) |

0.10-0.60mm x 450mm |

| Dimension of the machine (L x W x H) | 3800 x 920 x 1750 mm |

|

Weight |

1250 KG |

What is the main parts of this machine?

1. Plastic sheet placing device

2. Forming Device

3. Sheet Sending Device

4. Cutting Device

How this machine make products?

Plastic sheet heating---Forming---Automatic Cutting---En-products

Welcome to enquire Best selling plastic cup lid thermo forming punching machine with low price thank you!

Please click "Chat Now" at right column to send enquiry

FAQ:

Q1: With this machine, what materials we need to prepare so can start production?

Plastic sheet roll (PVC, PS or PET);

We can recommend our partners who can supply packing materials to you,

or we can coordinate good with your packing materials suppliers.

Q2: For running this machine, what other necessary equipment we need to prepare?

A: Air compressor(for supply air to machine) and tap water(for cooling mould)

Q3: What is the warranty, how you offer after service?

A: Machine warranty is 1 year.

In one year, any parts on machine have problem not due to wrong operating we can

send new parts to you by courier.

For installation or maitenance of machine, we send our engineer to your factory.

Q5: How to design machine products?

A: If you have products samples, pls send photos or samples to us, we make mould

drawing according to the sample and send you for confirmation.

If you only have idea, please share your idea with us, we make mould design according

to your idea, after discussion and correction, we can finalize the mould design.

All the mould will make according to your confirmed mould design.

Q6: In one machine we can make only one product or we can make different products?

A: In one machine, Sure you can make different products by change mould and filling device.

In this way you can make different new products according to market by low investment and risk.

For more questions please click "Chat Now" at right column

WHY CHOOSE US

Shantou Xinhua Packing Machinery Factory Co., Ltd was established on 1989, only by offered high quality machine and excellent after service made the company existed more than 25 years.

Purchasing machine is an investment,

Purchase machine from old factory will be a low-risk investment.

Punctual delivery time:

- We put your order into our tight production schedule, ensure your punctual delivery time.

- Production or inspection report before your order packed.

- Shipping notice/ insurance to you as soon as your order is shipped.

After sales service:

- We respect your feed back after receive the goods.

- We provide 12 months warranty after goods arrive.

- We promise all spare parts available in lifetime use.

- We have experienced engineer team and always ready to help you solve the problem in your factory.

Professional sales:

- We value every inquiry sent to us, ensure quick competitive offer.

- We not only can offer information of our machines but also can offer another information, such as: production line, packing materials, corollary equipment and ect.,

- We cooperate with customer to bid tenders. Provide all necessary documents.

- We are a sales team, with all technical support from engineer team.

- Customer is always welcome to visit our factory, we can picked you up from anywhere in our city