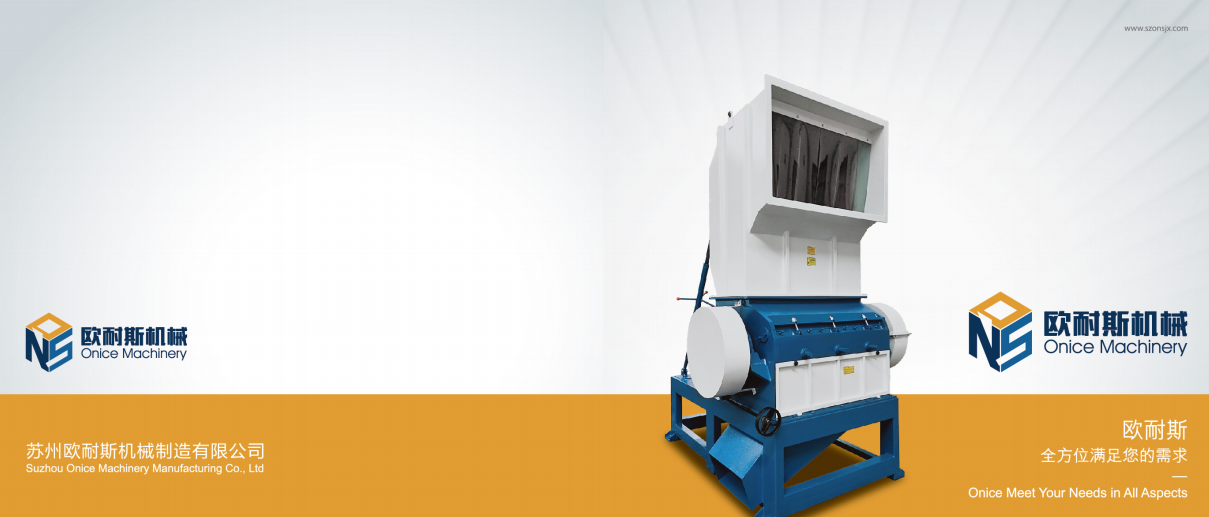

Plastic crusher is used for recycling waste materials in plastic industry. It is made up with hopper, cutting chamber, knife seat, cutting tool, motor, base and controlling cabinet. There is safety interlock between the feeding hopper and the chamber. The hopper is made of double-layer hollow steel board for reducing the noise. Protective curtain is also matched in with the feeding mouth to prevent the crushed materials out. The electrical system has grounding, voltage loss and overload protection with all the controlling device installed in the sealed box. Whole machine controlled by PLC, it will be set before delivery, non-professional man must not revise the PLC program.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

NS-D600

-

Voltage:

-

customize

-

Dimension(L*W*H):

-

2200X1200X2300

-

Year:

-

2022

-

Weight (KG):

-

2200 kg

-

Power (kW):

-

30

-

Color:

-

customize

-

Electrical appliance:

-

Electrical appliance

-

Feed port:

-

600mm*700mm

-

weight:

-

2200kg

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OUNAISI

-

Marketing Type:

-

Hot Product 2022

-

Model Number:

-

NS-D600

-

Voltage:

-

customize

-

Dimension(L*W*H):

-

2200X1200X2300

-

Year:

-

2022

-

Weight (KG):

-

2200 kg

-

Power (kW):

-

30

-

Color:

-

customize

-

Electrical appliance:

-

Electrical appliance

-

Feed port:

-

600mm*700mm

-

weight:

-

2200kg

Product Description

Parameter table

|

Model number

|

Motor power

|

Number of blades

|

Length, width and height

|

yield

|

|

NS-D600

|

30kw

|

29

|

2200X1200X2300

|

300-500kg/H

|

|

NS-D800

|

37kw

|

46

|

2700X1450X2300

|

500-800kg/H

|

|

NS-D1000

|

55kw

|

58

|

2700X1650X2500

|

800-1000KG/h

|

|

NS-D1200

|

75KW

|

82

|

3600X2200X2300

|

900-1100KG/h

|

|

NS-D1300

|

75KW

|

84

|

2700X1650X2500

|

1000-1200KG/h

|

Product Description

General introduction

Application

1. All kinds of hollow containers: plastic beverage cans, plastic barrels, drums, packing box, packing barrel

2. Waste appliances: TV, washing machine, refrigerator shell, printer, keyboard, waster Microwave oven,waster computer,waster

mouse,Circuit board.

3. Pipe: large pipe, pipe fittings, PE pipe,PVC tube.

4. Waste template: wooden pallets, plastic pallets, forklift pallets,Used furniture.

5. Scrap tires:car tires, truck tires, engineering tires.

6. Scrap metal: car shell, aluminum alloy, scrap aluminum castings, engine shell

7. Garbage:Food waste,animal carcass, medical waste, garden garbage,Fruit trash,Vegetable trash,glass.

8.Rubber head material, papper mill rope.

2. Waste appliances: TV, washing machine, refrigerator shell, printer, keyboard, waster Microwave oven,waster computer,waster

mouse,Circuit board.

3. Pipe: large pipe, pipe fittings, PE pipe,PVC tube.

4. Waste template: wooden pallets, plastic pallets, forklift pallets,Used furniture.

5. Scrap tires:car tires, truck tires, engineering tires.

6. Scrap metal: car shell, aluminum alloy, scrap aluminum castings, engine shell

7. Garbage:Food waste,animal carcass, medical waste, garden garbage,Fruit trash,Vegetable trash,glass.

8.Rubber head material, papper mill rope.

1.Heavy-duty construction and efficient performance are determined by the precisely processed combined frame made of extra-thick

plates

2. Wide angle, hexagon prism of power slewing axis; large hopper with big caliber for feeding large material

3. It adopts PLC control system, automatic overload protection and auto reverse switch

4. The low rotation speed results in a particularly quiet shredding process with low levels of dust generation

5. It can be adjusted according to customer specific requirements for throughput volume, material to be processed, etc

plates

2. Wide angle, hexagon prism of power slewing axis; large hopper with big caliber for feeding large material

3. It adopts PLC control system, automatic overload protection and auto reverse switch

4. The low rotation speed results in a particularly quiet shredding process with low levels of dust generation

5. It can be adjusted according to customer specific requirements for throughput volume, material to be processed, etc

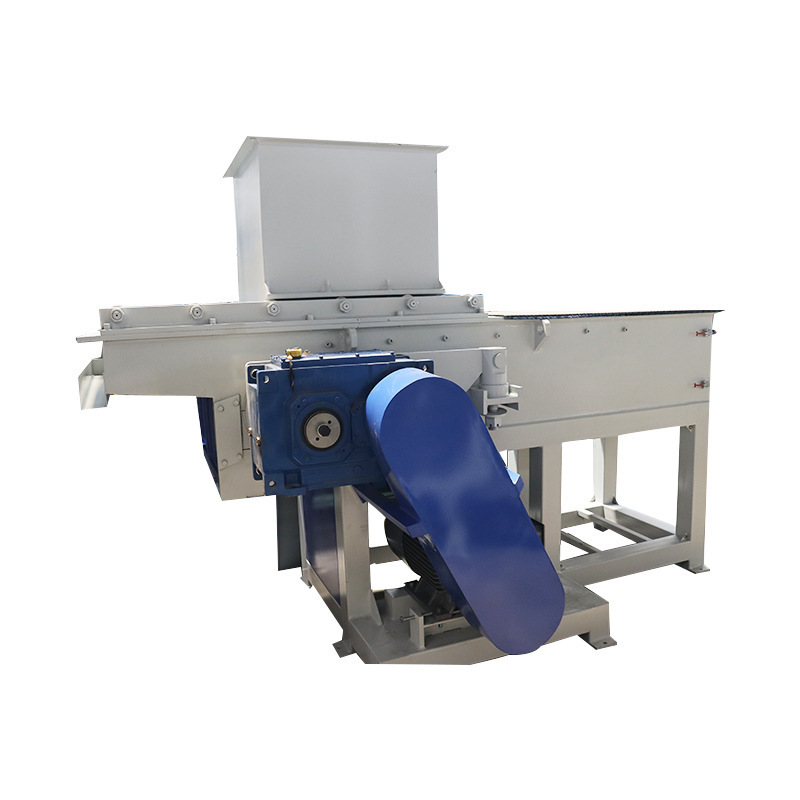

Product Detail

Belt Conveyor

● The plastic waste is conveyed into the shredder through the belt feeding device;

● The device adopts ABB/Schneider frequency

converter for frequency control.

● The conveying speed of the belt feeding device is linked with the fullness of the shredder, and

the speed of the conveyor belt is automatically adjusted according to the current of the shredder.

the speed of the conveyor belt is automatically adjusted according to the current of the shredder.

Metal Detector

● Optional Ferrous Metal Permanent Magnetic Belt or metal detector can prevent metal specials from entering the shredder and effectively protect the blades of the shredder.

Hopper

● Special designed hopper to avoid material flying out. The machine is fitted with a large filling hopper and can be loaded by

conveyor belt, fork lift, crane or wheel-loader. This funnel can be adapted to suit individual requirements and guarantees a

continuous and economical supply of material.

conveyor belt, fork lift, crane or wheel-loader. This funnel can be adapted to suit individual requirements and guarantees a

continuous and economical supply of material.

Hydraulic Ram

● The hydraulically operated pusher feeds the material towards the cutter automatically by load-related controls. The hydraulic

system is equipped with overflow valves and volumetric flow controls, which can be both set according to the demands of the input

materials.

system is equipped with overflow valves and volumetric flow controls, which can be both set according to the demands of the input

materials.

Rotor

● The rotor is made of seamless steel pips with the diameter of 560mm and operates at a speed of 72 rpm. The concave ground,

aggressive and 4-way rotating knives are mounted in the grooves of the rotor. This enables a reduction of the cutting gap between

the counter knives and the rotor and guarantees a high flow rate, low power consumption and maximum output of ground material.

aggressive and 4-way rotating knives are mounted in the grooves of the rotor. This enables a reduction of the cutting gap between

the counter knives and the rotor and guarantees a high flow rate, low power consumption and maximum output of ground material.

Knife Blades

● Knife Blades Material: DC53 Higher hardness (62-64 HRc) than D2/SKD11 after heat treatment.

● Twice the toughness of D2/SKD11

with superior wear resistance.

with superior wear resistance.

● Substantially higher fatigue strength compared to D2/SKD11.

Screen

● The screen mounted beneath the rotor determines the size of the required flakes. The screen is also easily accessible by a

separate flap and can be changed easily. The screen can be opened or closed hydraulically.

separate flap and can be changed easily. The screen can be opened or closed hydraulically.

Shredder Chamber

● The shredder chamber is welded with 30mm ultra-high hardness steel plate, which is wear-resistant, corrosion-resistant,

low-noise, and has a longer service life.

low-noise, and has a longer service life.

Motor

● Adopt imported brand motor WEG, low energy consumption, low noise, long service life.

Electronic Control

● The whole model adopts frequency conversion control and conforms to international standards such as CE/CSA.

Product Images

About Us

Hot Searches