- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99.9%

-

Voltage:

-

220V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

DEVELOP-MC

-

Dimension(L*W*H):

-

2500mm* 2000mm* 1700mm

-

Weight:

-

700 KG

Quick Details

-

Machinery Capacity:

-

30bottoles/min

-

Packaging Material:

-

Glass

-

Filling Material:

-

Other

-

Filling Accuracy:

-

99.9%

-

Voltage:

-

220V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

DEVELOP-MC

-

Dimension(L*W*H):

-

2500mm* 2000mm* 1700mm

-

Weight:

-

700 KG

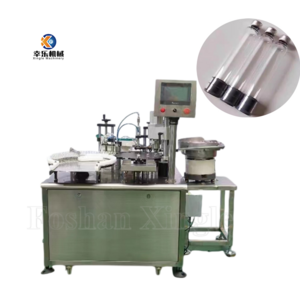

KS-2 Cartridge Plugging (Plungering) & Stoppering Filling And Capping Machine

Introduction

This machine is suitable for the packaging process of liquid filling , oral liquid, beverage, health care products, food, and other industries. The machine adopts screw feeding bottle, disc positioning filling, capping and capping, and the design is reasonable; quantitative filling, accurate measurement, especially suitable for filling of 1ml-5ml bottle; using peristaltic pump filling, 316L stainless steel Material; work surface is protected by stainless steel material, and the whole machine meets GMP requirements. The transmission of the machine adopts mechanical transmission, the transmission is accurate and stable, and there is no air source pollution and errors in the cooperation of various mechanisms. When working, the noise is small, the loss is low, the work is stable, and the output is stable. It is especially suitable for the production of small and medium-sized batches.

Work steps

1. Because the bottle is thin, the tray is placed, and the screw is bottled into the bottle.

2. The station turntable rotates automatically, and the bottle is sent to the production station. The rotation speed of the turntable matches the screw feed bottle.

3, the plug is automatically arranged by the vibrating plate, from the bottom of the plug, no bottle is not stuffed

4. Filling is filled by ceramic pump, no bottle is not filled

5, the cover is automatically sorted and supplied by the vibrating plate, no bottle is not covered

6. After the capping is completed, the cap is automatically rolled out.

Main technical parameters of filling and capping machine

2.1 Production capacity: 30~35 bottles/min

(2 heads filling with 1 head plugging and 1 head roll capping)

2.2 Production pass rate: not less than 98%

2.3 Power supply: 220V, 50Hz

2.4 total power: 2.0KW

2.5 Dimensions: 2500mm* 2000mm* 1700mm

2.6 weight: 700kg

Main component configuration list

|

|

name |

Specification model |

supplier |

|

machine Machinery unit Minut e |

Rack structure |

High quality carbon steel |

Shanghai Baosteel |

|

Equipment exterior material |

304 |

Shanghai Baosteel |

|

|

Filling needle |

316L |

Shanghai Baosteel |

|

|

Peristaltic pump |

|

Changzhou Kejian |

|

|

Conveyor chain |

Japan POM Engineering Plastics |

Shanghai Lisheng |

|

|

Linear Bearings |

Fully imported oil-free bearings |

Igus |

|

|

Capping head |

304 |

Shanghai Baosteel |

|

|

Main motor |

|

Shanghai Lichao |

|

|

Reducer |

|

Hangzhou Jiacheng |

|

|

Cam indexer |

|

Shandong Zhucheng |

|

|

Transmission component |

|

self made |

|

|

Electricity Device unit Minute |

breaker |

|

Schneider |

|

Contactor |

|

Schneider |

|

|

Relay |

|

Omron |

|

|

PLC |

|

Mitsubishi |

|

|

Screw cap motor |

|

Taiwanese Taisaki |