- Product Details

- {{item.text}}

Quick Details

-

Power:

-

5.5Kw-30Kw

-

Weight:

-

1000

-

Dimension(L*W*H):

-

Depends on the model

-

Application:

-

Sea salt, mineral salt

-

Sieve slot:

-

Customerized

-

MOC:

-

SS304,SS316,DUPLEX SS

-

Control:

-

PLC

-

Design:

-

Sulzer

-

Operation:

-

Continuous

-

Temperature allowed:

-

Below 105degree

-

Discharge:

-

Pushing type

-

Electrical elements:

-

Famous brand

-

Humidity in the cake:

-

Less than 4%

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Kingreat

-

Voltage:

-

220, 380, 440, 460V....

-

Power:

-

5.5Kw-30Kw

-

Weight:

-

1000

-

Dimension(L*W*H):

-

Depends on the model

-

Application:

-

Sea salt, mineral salt

-

Sieve slot:

-

Customerized

-

MOC:

-

SS304,SS316,DUPLEX SS

-

Control:

-

PLC

-

Design:

-

Sulzer

-

Operation:

-

Continuous

-

Temperature allowed:

-

Below 105degree

-

Discharge:

-

Pushing type

-

Electrical elements:

-

Famous brand

-

Humidity in the cake:

-

Less than 4%

PP Series horizontal pusher centrifuge is a kind of perforated basket centrifuge, both continuous and effective. The mixture to be separated is fed through the feeding pipe and the distributor continuously and evenly into the first stage basket. Most of the mother-liquor in the feed, acted on by centrifugal force, departs through the sieves into the liquor-collecting casing where it will be discharged out of the machine. The first stage basket rotates and reciprocate, pushing the formed product cake into the second stage basket .The cake can have sufficient retardation in the centrifuge with being acted on by more centrifugal force, and therefore, the desired humidity of the cake can be guaranteed. Afterwards, the cake is continuously discharged out of the basket. In case of high purity for the solid product, the effective washing can be carried out in the centrifuge. If necessary, the washing agent and the mother-liquor can be discharged separately.

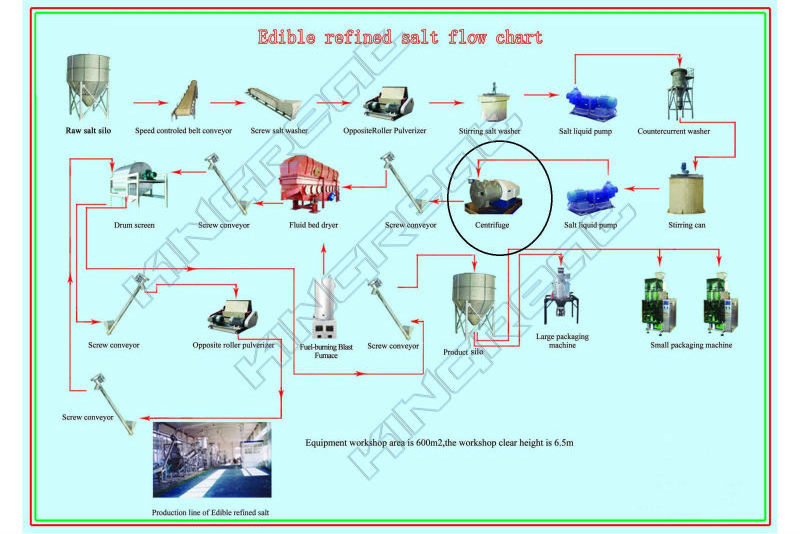

Process flow chart

Technical parameters

Salt production plant for salt crushing and washing is to produce salt with high quality. The equipment from raw salt to packing are all available.

The whole line includes the following equipments:

1. Salt feed hopper

2. Rationed screw conveyor

3. Pikcing belt machine

4. De-ironing separator

5. Screw washer

6. Roll crsher

7. Agitating salt wahser

8. Slurry pump

9. Agitating tank

10. Brine tank

11. Thickener

12. Centrifuge

13. Screw conveyor

etc.

14. Iodine adding machine

15. Vibration fluidized bed dryer

16. Cyclone dust extractor

17. Spray washer

1 8. Bucket elevator

19. Belt conveyor

20. Sewing sacks

21. LCD electronic scale

22. Chain grate coal-fired hot blast stove

23. Slag discharge machine

24. Coal conveyor

25. Electric control cabinet

26. Packing machine

1. 12 months guarantee period from machine arriving date.

2. Abundant spare parts in stock are available to provide.

3. Our technicians could be dispatched for overseas service.

4. 7*24 hours technical consultation.

5. Your workers could get trained both in our factory and yours.

6. Routine tracing till the machine work properly will be done timely.

7. We will remind you to do the normal maintenance.

8. Your suggestions or any comments & reflection would be treated in priority.

9. Marketing team will visit you during our visit in your country if you require.

Nanjing Kingreat Machinery Co., Ltd,

covering an area of 650000m2, there are 2300 staff and employee in our company, 281 of them are technicians and engineers. It has obtained the approvals and certifications of both ISO9001:2008 quality control system and the military product quality certificate, BV and CE certificates. Some of our machines gained the new technology invent patent.

We are one of the world's leading manufacturers of disc centrifuges, decanters, separation systems and marine equipment. We focus on food production, environmental protection, energy recycling, chemistry and marine. Now there are over 150 series of decanter centrifuges and disc separators used both home and abroad.