- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

-

-

CrO Content (%):

-

-

-

SiC Content (%):

-

-

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Magnesia aluminum spinel brick

-

Brand Name:

-

Kerui Refractory

-

Product Name:

-

Magnesia Aluminum Spinel Brick

-

Raw Material:

-

Magnesia

-

Size:

-

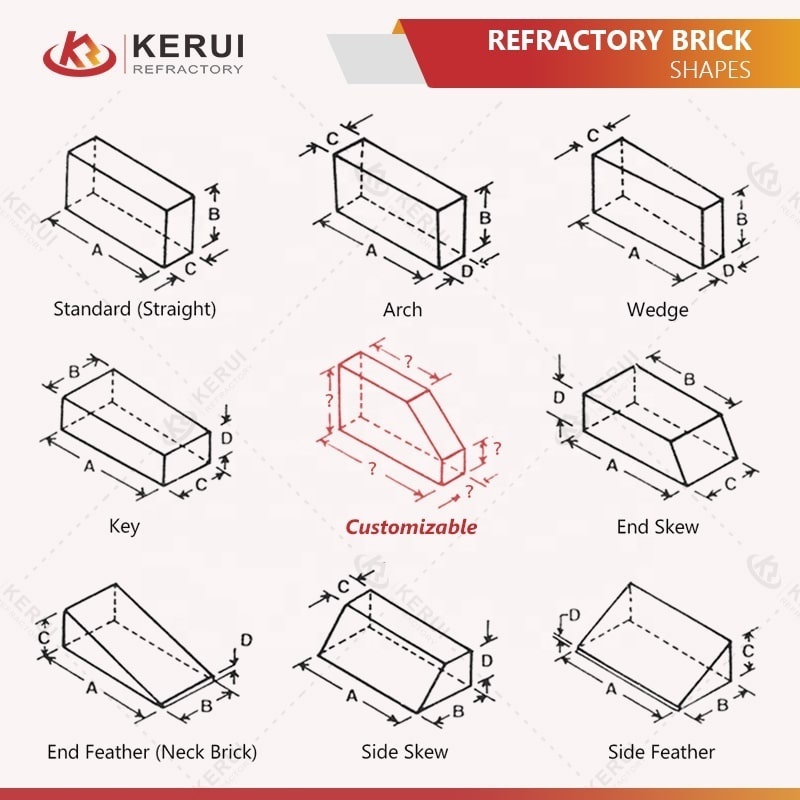

230x114x65mm or Customized

-

Certificate:

-

ISO9001;ISO14001;OHSAS18001

-

Application:

-

Cement Kiln

-

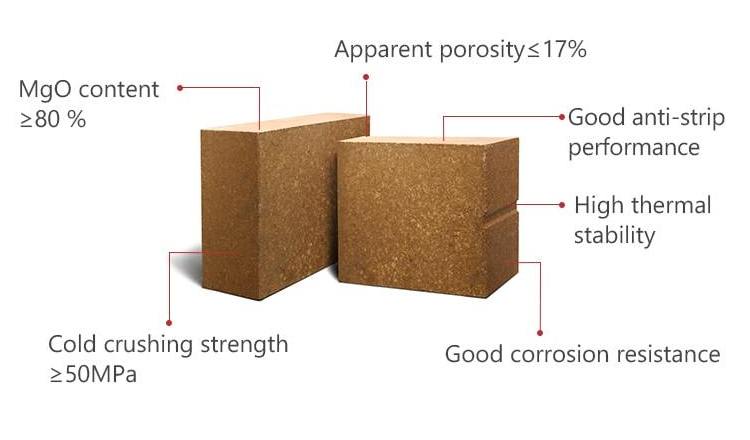

Apparent Porosity:

-

≤17%

-

Bulk Density:

-

≥2.9g/cm³

-

Cold Crushing Strength:

-

≥50MPa

Quick Details

-

SiO2 Content (%):

-

-

-

Al2O3 Content (%):

-

≥10%

-

MgO Content (%):

-

≥80%

-

CaO Content (%):

-

-

-

CrO Content (%):

-

-

-

SiC Content (%):

-

-

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Magnesia aluminum spinel brick

-

Brand Name:

-

Kerui Refractory

-

Product Name:

-

Magnesia Aluminum Spinel Brick

-

Raw Material:

-

Magnesia

-

Size:

-

230x114x65mm or Customized

-

Certificate:

-

ISO9001;ISO14001;OHSAS18001

-

Application:

-

Cement Kiln

-

Apparent Porosity:

-

≤17%

-

Bulk Density:

-

≥2.9g/cm³

-

Cold Crushing Strength:

-

≥50MPa

Product Description

Magnesia spinel brick is a kind of alkaline refractory product with periclase as main phase magnesite-alumina spinel clinker as basic material. The product has such characteristics as good temperature vibration, good strength and volume stablity in high temperature. Magnesia alumina spinel bricks typically consists of 80% of magnesia, which provides excellent resistance to basic environments. As the amount of spinel increases, the thermal shock resistance of the brick becomes better. To avoid the hardness of brick, Kerui also adds some Al

2

O

3

to make up this property.

Specification

|

Item

|

|

Index

|

|

|

MgO, %

|

≥

|

80

|

|

|

Al2O3, %

|

≥

|

10

|

|

|

Apparent Porosity, %

|

≤

|

17

|

|

|

Bulk Density, g/cm³

|

≥

|

2.9

|

|

|

Cold Crushing Strength, MPa

|

≥

|

50

|

|

|

High-temperature Bending Strength (1350℃*0.5h), MPa

|

≥

|

3.5

|

|

|

Thermal Shock Resistances (1100℃, Water Cooling), Cycle

|

≥

|

12

|

|

Key Features

Refractory bricks are characterized by their ease of installation, thermal insulation, heat resistance, wear resistance, and chemical erosion resistance. They protect the

furnace

shell and are ideal for use in various industrial high-temperature kilns.

Strong adhesion of kiln skin

Magnesia-alumina spinel brick

formed a protective layer on the surface of the cement kiln with the substances generated during its operation.

Thermal shock stability

Magnesia-alumina spinel bricks with higher thermal shock stability can exhibit a longer service life, helping to improve the overall efficiency of the kiln.

Environmental friendly

The brick avoid chromium pollution and do not produce harmful substances to the environment during preparation and use.

Processing customization

We can provide customized one-stop production and processing services according to customer requirements.

Good slag resistance

The

brick is

alkaline refractory materials with periclase as the main crystal phase and high melting point second solid phase as the main bonding phase, and less glass phase.

Applicable to multiple ranges

The brick is

mainly used in constructing open-hearth furnace tops, electric furnace tops, external refining furnaces and various alkali-resistant non-ferrous metal smelting furnaces.

Applications

Cement Industry

Magnesia alumina spinel

brick

is

used in cement kilns and other cement production equipment.

Power Station Industry

Refractory bricks

are used in boilers, incinerators, and other high-temperature equipment in power plants.

Glass Industry

Refractory bricks are

used in glass melting furnaces and regenerators.

Petrochemical Industry

Refractory bricks are

utilized in kilns and furnaces for ceramic production.

Steel Industry

Refractory bricks are

extensively used to line the steel ladles, blast furnaces, and other high-temperature equipment.

Ceramic Industry

Refractory bricks are

used in petrochemical processes, such as the construction of cracking furnaces and reformers.

Production Process

KERUI Refractory

Zhengzhou Kerui (Group) Refractory Co., Ltd.

is located in China’s largest refractory industry zone: Chaohua Town, Xinmi City, Henan Province.

KERUI Refractory strives to provide top-notch solutions and services for high-temperature industries worldwide, including iron steel, aluminum, power, glass, boiler, non-ferrous, cement industry, etc.

KERUI has a diverse and extensive global customer base, with clients located in various regions around the world. our high-quality products and services have earned us a reputation for excellence, making us a preferred choice for many industries.

Our commitment to quality and customer satisfaction has allowed us to build strong relationships with clients in North America, South America, Europe, Asia, Africa, and beyond. We continually strive to exceed our customers' expectations, delivering reliable products and exceptional service at all times.

We work closely with our customers to understand their unique needs, providing tailored solutions that meet their specific requirements.

KERUI Refractory strives to provide top-notch solutions and services for high-temperature industries worldwide, including iron steel, aluminum, power, glass, boiler, non-ferrous, cement industry, etc.

KERUI has a diverse and extensive global customer base, with clients located in various regions around the world. our high-quality products and services have earned us a reputation for excellence, making us a preferred choice for many industries.

Our commitment to quality and customer satisfaction has allowed us to build strong relationships with clients in North America, South America, Europe, Asia, Africa, and beyond. We continually strive to exceed our customers' expectations, delivering reliable products and exceptional service at all times.

We work closely with our customers to understand their unique needs, providing tailored solutions that meet their specific requirements.

With feasible solutions and considerate service, Kerui has dece loped stable cooperation relationships with global customers.

Our cooperation is based on a common win-win goal. Together with Kerui, we can create innovative solutions and realize your success in high temperature industries.

Our cooperation is based on a common win-win goal. Together with Kerui, we can create innovative solutions and realize your success in high temperature industries.

FAQ

1. Are we a manufacturer or supplier?

We have surely been a reliable manufacturer since 2004.

2. OEM, ODM?

Most certainly, we can also customizable to meet unique requirements, for instance, indicators, sizes, etc.

3. Project questions, such as kiln maintenance, available for consultation?

Yes, PLEASE, We have experienced product technical consultants to communicate online.

4. How do you conduct quality testing on your products?

We strictly follow the quality management system, and we have a logistics chemistry laboratory. Here are some of the ways we conduct quality testing:

1) Raw material inspection

2) In-process inspection

3) Finished product inspection

4) Performance testing

5) Stability testing

5. How can I get a sample?

Sure, before your first purchase order, you can get a free test sample.

We have surely been a reliable manufacturer since 2004.

2. OEM, ODM?

Most certainly, we can also customizable to meet unique requirements, for instance, indicators, sizes, etc.

3. Project questions, such as kiln maintenance, available for consultation?

Yes, PLEASE, We have experienced product technical consultants to communicate online.

4. How do you conduct quality testing on your products?

We strictly follow the quality management system, and we have a logistics chemistry laboratory. Here are some of the ways we conduct quality testing:

1) Raw material inspection

2) In-process inspection

3) Finished product inspection

4) Performance testing

5) Stability testing

5. How can I get a sample?

Sure, before your first purchase order, you can get a free test sample.

Hot Searches