- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

500

-

Voltage:

-

380V 50Hz,3PH (Customized)

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Leadworld

-

Dimension(L*W*H):

-

2800*1500*1900mm/can be customized

-

Product name:

-

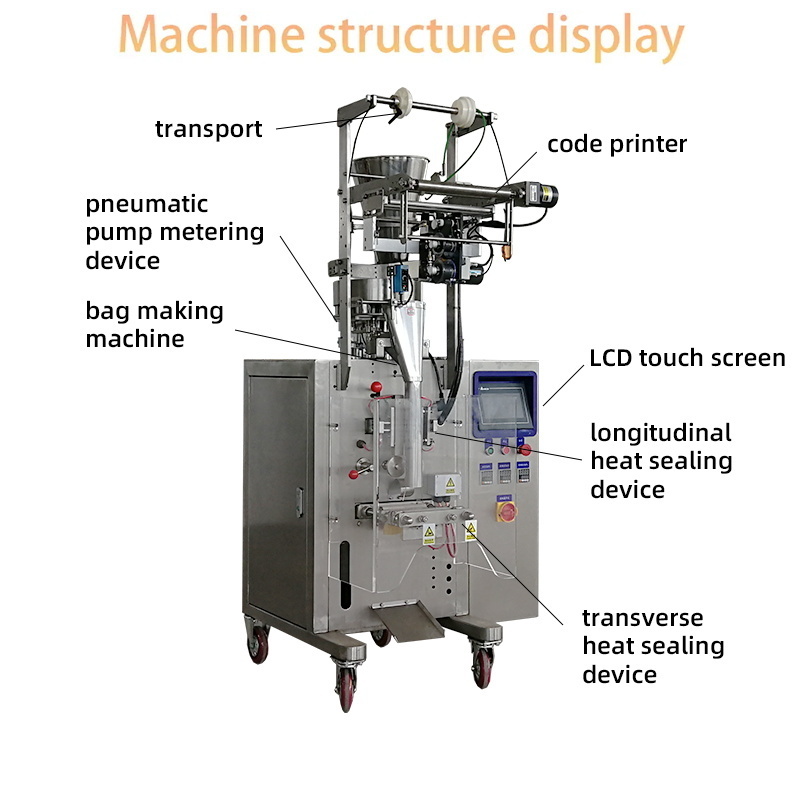

Automatic Packing Machine

-

Main Function:

-

Weighing Forming Filling Sealing

-

Packing speed:

-

30-80bags/min

-

Material:

-

Stainless Steel 304/316

-

Bag type:

-

3 Sides Seal/Back Seal

-

After-sales Service Provided:

-

Online Support

-

Usage:

-

Bag Making Filling Sealing

-

Keyword:

-

Packaging Machinery Equipment

Quick Details

-

Function:

-

FILLING, Wrapping, Capping, Sealing

-

Packaging Type:

-

Stand-up Pouch, Bags, Film, Pouch

-

Packaging Material:

-

Plastic, Paper, Metal

-

Weight (KG):

-

500

-

Voltage:

-

380V 50Hz,3PH (Customized)

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Leadworld

-

Dimension(L*W*H):

-

2800*1500*1900mm/can be customized

-

Product name:

-

Automatic Packing Machine

-

Main Function:

-

Weighing Forming Filling Sealing

-

Packing speed:

-

30-80bags/min

-

Material:

-

Stainless Steel 304/316

-

Bag type:

-

3 Sides Seal/Back Seal

-

After-sales Service Provided:

-

Online Support

-

Usage:

-

Bag Making Filling Sealing

-

Keyword:

-

Packaging Machinery Equipment

Product Show

Optional Products

|

Platform

|

|

|

Elevator

|

|

||

|

Model

|

LWT-2Platform

|

|

Model

|

LWT-300

|

||

|

Maximum Loading Weight

|

2T-3T

|

|

Convey speed

|

3750mm/min

|

||

|

Equipment Size

|

2000mm*2000mm*2000mm

|

|

Power

|

750W

|

||

|

Net Weight

|

350kg

|

|

Convey Measure

|

4T/H(Rice)

|

||

|

|

|

|

Overall size

|

3000(L)×650(W)×3750(H)mm

|

||

|

Collecting table

|

|

|

Bag former

|

|

||

|

Model

|

LWT-C

|

|

Packing machine has one bag forming tube. If the bag width is fixed, no need to buy extra tube. If you have different bag widths,

you have to buy extra tubes. For example, you have 3 bag widths, you have to buy extra two tubes. If only the bag length change, no need to buy extra bag forming tube. You can modify the parameter on the touch screen. |

|

||

|

Convey speed

|

Speed can be changed(fast or slow depends on your choice)

|

|

|

|

||

|

Diameter

|

1.2m

|

|

|

|

||

|

Surface

|

Concave

|

|

|

|

||

|

Power

|

220V/370W/50HZ

|

|

|

|

||

|

Weight of machine

|

100KG

|

|

|

|

||

|

Packaging size

|

1300mm(L)*380mm(W)*1300mm(H)

|

|

|

|

||

Detailed instruction:

1.Conveyor body part:

1.1 Main body side chain plate:Plate thickness:δ2.0mm Material:SUS304.

When produced according to the actual size.

1.2 Roller:Material SUS304,diameter is based one the actual

load,cooperate with the plus or minus tolerance.

1.3 Riding wheel:Material Nylon processing molding,diameter is based one the actual load,cooperate with the plus or minus tolerance.

1.4 Bun foot:Nylon injection molding,Cooperate with stainless steel adjusting screw M16.

1.5 Guardrail part adopts big Caluminum trackCooperate with wear-resisting sheath;

1.6 Connecting plate:plate wicknessδ3.0mm Material:Stainless steel bending forming;

1.7 Accessories:Mounted Bearings、kinds of SUS304 screws,etc.

2.Conveying carrier part

2.1 Belt length

Explanation of the design plan

⚫

According to the product information described by the customer, our company recommends the use of a stainless steel computerized automatic double-layer water bath/steam sterilizer.

⚫ The hot water is stored in the upper tank, which can be quickly filled during sterilization, the product heats up quickly, the product is completely immersed in the sterilization water, the temperature penetrates into the product in all directions, and the product matures quickly.

⚫ The design of this product is based on canned and flexible packaging sterilization, excluding glass bottles, the heating method is direct heating by a heating tube, the sterilization method is a circulating water bath, and the cooling method is

The formula is direct cooling.

⚫ The control method is fully automatic computer control, the operator is only responsible for entering and leaving the sterilization material, all sterilization processes are automatically controlled, and can also be manually controlled.

⚫ The quality of the equipment is stable, durable, and the optimally designed sealing structure is more durable and easy to maintain; easy to operate and easy to install, according to ergonomic

The design makes the machine safer and more convenient.

|

project

|

Content

|

|

Retort inner diameter/cylinder length/volume

|

1200mm /3600mm /about 4.5m3

|

|

Effective use size of sterilizer (length/width/volume)

|

3600mm /800mm /800mm

|

|

design pressure

|

0.35Mpa

|

|

maximum working pressure

|

0.3Mpa

|

|

Pressure test pressure

|

0.44Mpa

|

|

maximum operating temperature

|

143℃

|

|

total installed power

|

Water pump 7.5kw,cycle pump 5.5kw,exchange use

|

|

voltage

|

380V

|

|

Pot body material

|

SUS30408

|

|

pot body wall thickness

|

5mm

|

|

Footprint (L/W/H)

|

About 5500mm×2200mm×3100mm

|

Hot Searches