- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110V 220V 380V 415V 440V

-

Power:

-

80- 120 Kw

-

Weight:

-

3800 KG

-

Dimension(L*W*H):

-

15000*2000*3000

-

Product name:

-

Pet Food Production Line Dog Food Making Machine

-

Raw material:

-

fish meal, Corn powder, protein powder

-

Main Motor:

-

Sienmens, ABB, OMRON

-

Advantages:

-

Full automatic, low cost, high efficiency and so on.

-

Key Selling Points:

-

110V 220V 380V 415V 440V

-

Usage:

-

fish , Pet feed production

-

Machine material:

-

National Standard Carbon Steel

-

Advantage:

-

Easy Operation High Efficiency

-

web:

-

www.fldmachine.com

-

Energy:

-

electricity gas dissel steam

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FLDMACHINE

-

Voltage:

-

110V 220V 380V 415V 440V

-

Power:

-

80- 120 Kw

-

Weight:

-

3800 KG

-

Dimension(L*W*H):

-

15000*2000*3000

-

Product name:

-

Pet Food Production Line Dog Food Making Machine

-

Raw material:

-

fish meal, Corn powder, protein powder

-

Main Motor:

-

Sienmens, ABB, OMRON

-

Advantages:

-

Full automatic, low cost, high efficiency and so on.

-

Key Selling Points:

-

110V 220V 380V 415V 440V

-

Usage:

-

fish , Pet feed production

-

Machine material:

-

National Standard Carbon Steel

-

Advantage:

-

Easy Operation High Efficiency

-

web:

-

www.fldmachine.com

-

Energy:

-

electricity gas dissel steam

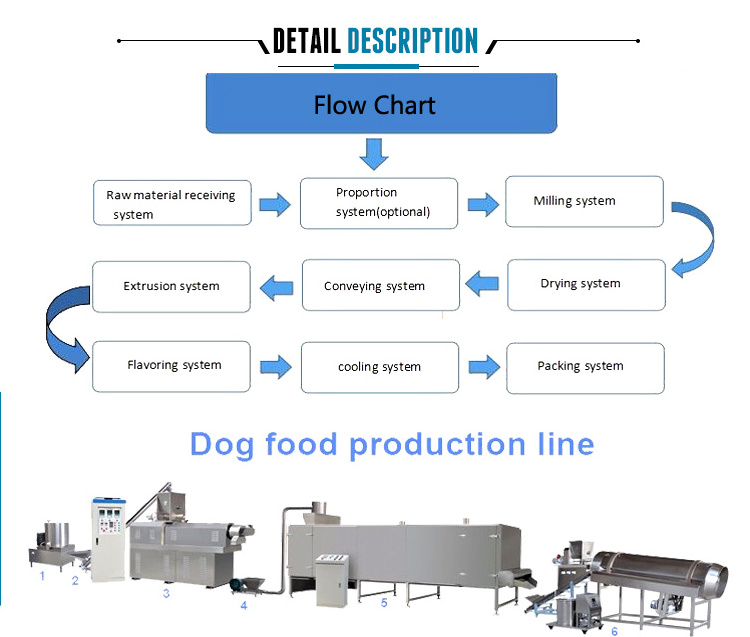

Product Description

Twin Screw Extruder Automatic Pet Food Production Line Dog Food Making Machine

1.Description of Pet Food Production Line:

1).Our dry dog food making machine adopt international advanced technology, the pellets size are very even.

2).we can adjust the cutter speed and the dies to get the different diameter and the length product

3).The Electric heating device system can control the temperature accurately

4).High temperature and high pressure can kill the salmonellosis andbacterial infections.

5).This Pet food making machine line can produce high-protein dog food.

6).This Dog food extruder machine line only need three workers

1.Raw Materials: Meat Meal, Fish Meal, Corn Powder, Soya Meal and Other Grain Powder

1).Our dry dog food making machine adopt international advanced technology, the pellets size are very even.

2).we can adjust the cutter speed and the dies to get the different diameter and the length product

3).The Electric heating device system can control the temperature accurately

4).High temperature and high pressure can kill the salmonellosis andbacterial infections.

5).This Pet food making machine line can produce high-protein dog food.

6).This Dog food extruder machine line only need three workers

1.Raw Materials: Meat Meal, Fish Meal, Corn Powder, Soya Meal and Other Grain Powder

2.Products: Pet Food, Like Dog, Cat, Fish, Bird Food etc. with Different Shapes and Tastes by

Changing the Dies and Formulations.

3.Dog food machine Capacity: 120-150 KG/H,200-250 KG/H,400-500 KG/H,800-1000 KG/H.

4.Voltage: Three phases: 380V/50HZ, Single phase: 220V/50HZ, we can make it according to

customers' local voltage according to different countries.

Changing the Dies and Formulations.

3.Dog food machine Capacity: 120-150 KG/H,200-250 KG/H,400-500 KG/H,800-1000 KG/H.

4.Voltage: Three phases: 380V/50HZ, Single phase: 220V/50HZ, we can make it according to

customers' local voltage according to different countries.

Specification

|

Model

|

FLD-SLG65

|

FLD-SLG70

|

FLD-SLG75

|

FLD-SLG85

|

FLD-SLG95

|

|

Install power

|

76KW

|

95kw

|

130kw

|

178kw

|

280kw

|

|

Production Catapacity

|

120-150kg/h

|

200-260kg/h

|

300-400KG/H

|

400-600kg/h

|

1000-1500kg/h

|

|

Size CM

|

1600*1800*2000

|

1800*2000*2200

|

2200*2000*2200

|

2500*2600*3000

|

3000*3200*3500

|

7.Pet food pellet processing making extruder machine making sample

This Pet food processing line can be used to produce fish pellets, the pellets size can be from 1.0 mm to 9.0 mm by adjusting the moulds from extruder; meanwhile it can produce dog food, cat food.....

8.Pet food extruder machine line Product Details:

Mixer→screw conveyor→twin screw extruder→air conveyor→dryer→hoister→flavoring drum and oil sprayer→cooling machine→packing machine

Packing & Delivery

Machines will be packed into wooden cases or wrapped by plastic film. Firstly, anti-rust oil is painted onto the machine, then wrap film and air bubble pad then to export non-fumigation wooden cases outside. Containers will be sent to our factory to load the machines and will be sealed before being sent out to make sure the safety of our machines.

Hot Searches