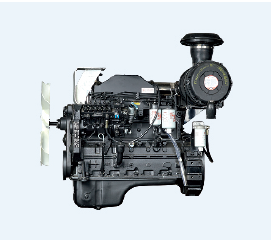

Cummins engine, designed for performance, durability and fuel economy, with G3 emission level. Widely environmental suitability: temperature from -42 to 55°C, humidity less than 90%.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

WINCOO

-

Product name:

-

Paywelder

-

Application:

-

welding station

-

After-sales Service Provided:

-

VIDEO SUPPORT

-

Keywords:

-

Welding tractor

Quick Details

-

Weight (KG):

-

13000

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

WINCOO

-

Product name:

-

Paywelder

-

Application:

-

welding station

-

After-sales Service Provided:

-

VIDEO SUPPORT

-

Keywords:

-

Welding tractor

WINCOO ENGINEERING CO.,LTD

Wincoo Engineering Co., Ltd (WINCOO) is engaged in bringing the most suitable solutions/equipment for client, fabricators, EPC/C companies on pipe fabrication, tank construction, pipeline construction, industrial production lines, clean energy project and other industrial field.

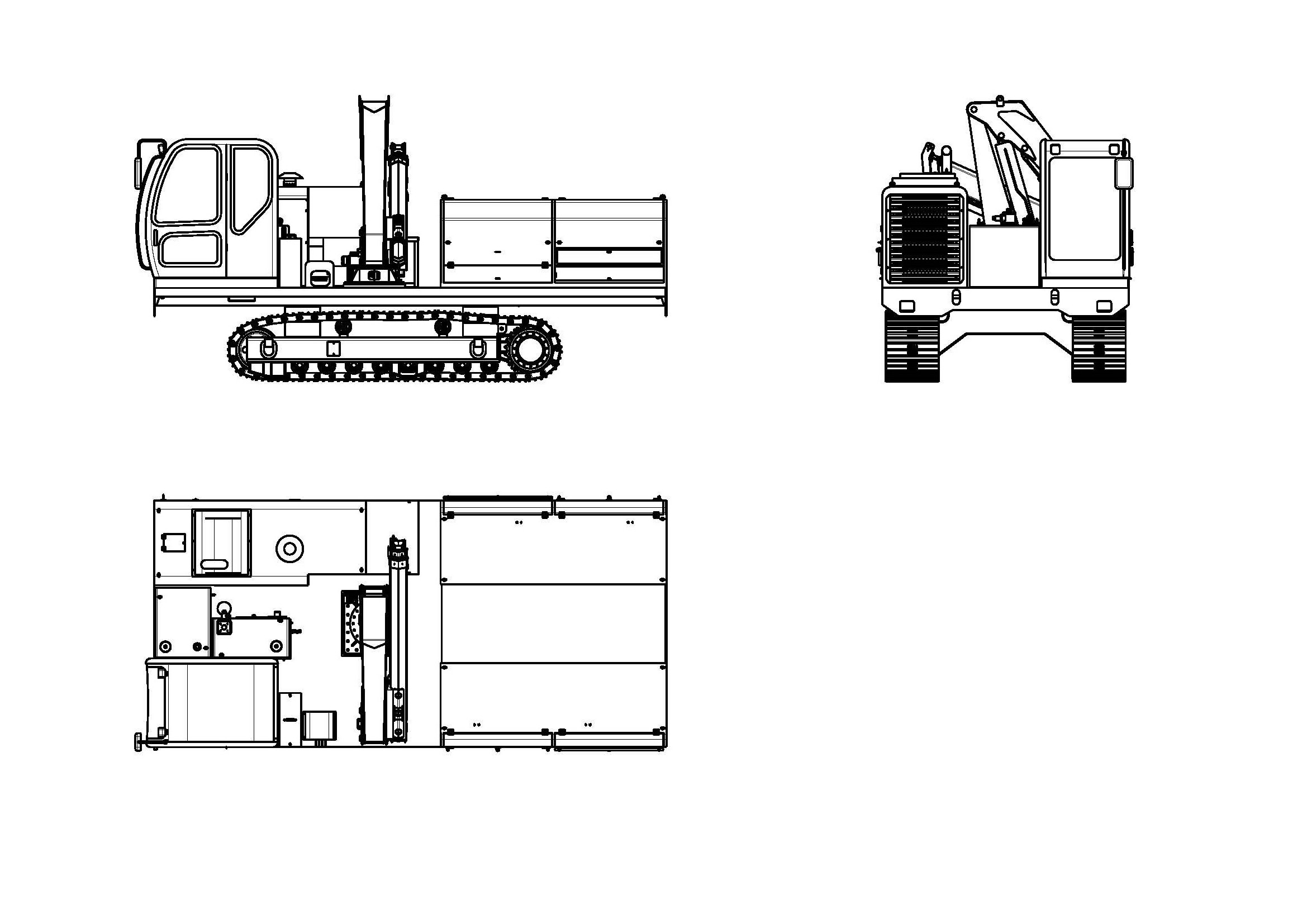

HG series welding tractor,also known as pay welder,is the perfect choice for pipeline welding.The strong power,efficient

transmission and robust undercarriage make it suitable for severe working condition. It is designed to be easily maintained at site: all its components such as engine, generator, crane, hydraulic pump and so on have selected from top suppliers with a global assistance network. What's more, to give maximum flexibility and value-for-money at site. HG series welding tractor can be customized as per your requirement.

transmission and robust undercarriage make it suitable for severe working condition. It is designed to be easily maintained at site: all its components such as engine, generator, crane, hydraulic pump and so on have selected from top suppliers with a global assistance network. What's more, to give maximum flexibility and value-for-money at site. HG series welding tractor can be customized as per your requirement.

Products Description

HG series welding workstation is a pipeline welding equipment developed by our company according to the technical development requirements of long-distance pipeline and the experience of similar products at home and abroad.The use of full hydraulic drive walking technology, the main components of the use of international famous hydraulic components, improve the technical performance and reliability of the vehicle, reach the level of similar products abroad. Can carry electric welding machine, air compressor and other equipment.

HG series welding workstation adopts internationally renowned brand diesel engine as power source, and the vehicle-mounted power generation system has external power supply capacity of 160kva.The power generation system adopts the form of direct transmission, which has the advantages of simple structure, less fault points, small volume, high efficiency, stable transmission, low noise and low energy consumption. This machine USES the full rigid chassis, according to the welding work station operation characteristic specially design the full hydraulic drive walking system, the off-road ability is strong, except may in the general area road driving, but also is suitable in the desert, the loose soil, the plateau and so on environment bad area carries on the large field engineering construction operation.

The cover parts of the machine adopt the design of left and right door, convenient for daily maintenance. The car is also equipped with a toolbox to facilitate the storage of small work tools.

Product Major Component

I. Engine

Cummins 6btaa-5.9-c202 (2200) four stroke, turbocharged, direct electric start, water cooled diesel engine.

The engine has high power reserve, strong power, stable power generation quality and convenient maintenance. The standard engine, with its improved engine cooling system and large water tank structure, has been able to withstand the high temperature environment of the pipeline bureau in India and the low temperature environment of the Russian engineering.

The standard equipment has been equipped with an air prefilter, which can remove 95% of the dust and impurities in the air intake system by adding an air prefilter, which can extend the cleaning and replacement time of air filter element by 6 to 10 times, reduce the early wear of the engine, extend the service life of the engine, and improve the adaptability of the equipment to the environment.

II. P ower generation system

The power part of the generator adopts cummins brand, and the generator adopts Stanford products of international famous brand.

Model: No. UCI274F

Rated output power: 160 KVA

Anti-corrosion measures: Three anti - paint treatment

Generator output: Three - phase four - wire system

Power generation system features:

1) Neutral suspension design, zero line is not grounded.

2) The main power generation switch has the functions of preventing missing phase, over current and electric shock.

3) The circuit breakers of each phase division are in case of missing phase, over current and electric shock.

4) All plugs shall be waterproof.

III. T ravel system

Chassis for imported hydraulic excavator chassis technology, combining with the working condition of hydraulic mobile power station demand, customized special chassis, firm structure, strong carrying capacity, good stability, excellent platform to expand, to avoid the excavator chassis transformation lead to the vehicle development, the carrying capacity and the poor, the poor poor damping and stiffness; The walking system adopts "four wheels and one belt" and tensioning mechanism, which has strong versatility, good interchangeability and reliable quality. The standard equipment is 600mm three-rib track plate. Different from the fully hydraulic mobile power station with excavator chassis transformation, the products provided by our company have one more set of supporting wheels, with 7 supporting wheels on each side, which increases the length of grounding, enhances the stability of the vehicle, especially ensures the climbing stability, improves the climbing ability, and makes driving smooth and safe.

The minimum clearance from the ground is 560mm, the approach Angle is 35°, and the departure Angle is 38°.Based on past product, the bottom of the form structure of engine and transmission system maintenance, maintenance is convenient, the bottom of the form to the palm result in wading ability is poor, easy to store in the bottom of a ship form sediment and other sundry cannot discharge affect defects such as service life of equipment, the products of our company cancelled the bottom of the form is fully closed structure, with eight beam frame structure, the engine and transmission, etc. Most of the parts above the platform, the equipment maintenance convenient, wading ability strong, depth of up to 1100 mm.

Adopting hydraulic transmission technology, the left and right tracks are controlled by the two handles respectively, which can realize both unilateral steering and in-situ steering. It has the characteristics of easy to learn, light and flexible, safe and reliable.

Braking system to mature to avoid braking system, vehicle braking and parking brake and walking motor and reducer integrated together, with functions of linkage, which is operating the handle of driving, braking system automatically lifted, to driving, the handle back to the median, automatic braking, brake system can parking brake, to ensure that the braking system operation is flexible, safe and reliable braking.

Fully hydraulic driven crawler undercarriage, with robust design, strong off-road capacity and reliable braking performance.

IV. H ydraulic system

The chassis hydraulic system adopts the load sensitive hydraulic system of American Danfoss and Doosan with mature excavator technology, which belongs to closed hydraulic system.

The crane system adopts the mature open valve control hydraulic system, which is composed of gear pump, hydraulic winch, hydraulic cylinder, multi-way valve and balance valve.

Our company adhering to the optimization, and vertical and horizontal pipeline, soft hard couple, orderly, reasonable and reliable fixed protection design concept of hydraulic pipeline design and installation, main hydraulic parts and pipe on the platform at a glance, the staggered, in the platform of the hydraulic components just remove the cover a little bolt can be convenient to maintenance, so the vehicle hydraulic system parts are easy to repair and maintenance, all the rated pressure on pipeline are higher than that of the hydraulic pressure of 1.5 times. Manuli hydraulic hoses and seals produced by Italian professional technology are suitable for normal operation of the equipment under the ambient temperature of -40 ℃ -- + 50 ℃.

V. Lifting system

Crane standard configuration adopts special crane for construction vehicle, 360° continuous rotation; The crane is a folding boom crane; Maximum working range 8.5m; Maximum lifting torque 132.3 kn.m; Rated hoisting load: 6.3t. Boom amplitude variation form: hydraulic cylinder amplitude variation.

PALFINGER crane, world famous brand, hydraulic driven telescopic boom,360° rotation. (Other brand are available)

VI. Man-Machine

Adopt excavator cab, it adopts streamline design, mold pressing molding process, the whole is beautiful and generous. The all-glass front windshield on the cab, wide sliding Windows on three sides, and Windows in the lower left corner ensure the driver's wide vision, convenient communication with the outside world, and easier driving. Airbag seals are installed in all moving parts of the cab to ensure good tightness of the cab.

The whole cab adopts hydraulic damping to reduce vibration, which effectively eliminates the damage of the whole machine vibration to the people and things in the cab, and greatly improves the comfort of the operators.

The driver's door lock is made of steel, which is mainly used for the driver's door lock of excavators such as Hitachi and Hyundai. The materials are mainly ST12 steel, 45 # and 10 # steel. Cab pin shaft is made of 35# cast steel.

VII. Carrying capacity

The carrying capacity of the platform is 9t; Platform size: 5740mm×2800mm.The DC400 / NL23P semi-automatic welder (including connecting power cables, wiring, etc.) and air compressor manufactured in the United States can be installed in a mobile power station to meet the service conditions.

The rear cabinet structure design is reasonable, adopts the modular split design concept, and effectively expands the installation space and heat dissipation space. The engine and generator are arranged on the right side of the cabinet, and the whole space on the left side is divided into two open areas. Adequate installation and operation space is provided for installation and maintenance of the welder.

In order to reduce the vibration of the whole machine, a special support and shock absorber are provided. The vibration of the machine to pick up equipment has both high and low frequency vibration, high frequency low-rising vibration in order to prevent carrying equipment damaged by vibration, vibration isolation, need to be based on the shock absorption belongs to passive vibration isolation, and some carry equipment installation foot strength low two factors, pipeline company random for carrying equipment such as electric control cabinet and electric welding machine special mounting bracket and a dedicated contact area larger rubber shock absorber, as shown in the figure below, ensure that meet the requirements of field construction.

VIII. Safety device

Safety locking device, the operator can pull up the operating lever after leaving the cab, and the equipment is in a stop state to prevent accidental driving; monitoring instrument of the supplied equipment has the display alarm function of engine water temperature, oil temperature too high, oil pressure too low and the protection function of automatic stop.

The equipment is equipped with necessary electrical short circuit protection device, complete insurance and two level leakage protection switch to ensure the safety of operators and equipment.

The equipment installation is convenient and quick, the operation time is shortened, the maintenance is simple.

1, Daily maintenance parts are arranged in the external, easy to operate.

2, Adopt maintenance-free power transmission parts, greatly reduce the maintenance workload.

3, The engine has a pre-filter which greatly extends the maintenance period and the service life of the equipment.

Product Parameters

|

Table of technical parameters

|

|

|

|

|

||||

|

Model No.

|

HG85

|

HG100

|

HG125

|

HG160

|

||||

|

Overall dimensions/L*D*H(mm)

|

4620*2300*2930

|

5150*2370*2955

|

5150*2370*2955

|

6310*3000*3300

|

||||

|

Operating weight without load

|

8.8T

|

10T

|

10T

|

13T

|

||||

|

Crawler contact ground specific pressure

|

28.5Kpa

|

28.5Kpa

|

28.5Kpa

|

28.5Kpa

|

||||

|

Gradeability

|

≤30 degrees

|

≤30 degrees

|

≤30 degrees

|

≤30 degrees

|

||||

|

Traction

|

≤91kn

|

≤91kn

|

≤91kn

|

≤91kn

|

||||

|

Driving speed-low speed

|

0~2.9km/h

|

0~2.9km/h

|

0~2.9km/h

|

0~3.7km/h

|

||||

|

Driving speed-high speed

|

0~4.6km/h

|

0~4.6km/h

|

0~4.6km/h

|

0~6.4km/h

|

||||

|

Min groud clearance

|

450mm

|

600mm

|

600mm

|

600mm

|

||||

|

Track grouding length

|

2800mm

|

2760mm

|

2760mm

|

3100mm

|

||||

|

Track spacing

|

1750mm

|

1770mm

|

1770mm

|

2150mm

|

||||

|

Track width

|

480mm

|

570mm

|

570mm

|

570m

|

||||

|

Basic machine data

|

|

|

|

|

||||

|

Model No.

|

HG85

|

HG100

|

HG125

|

HG160

|

||||

|

ENGINE

|

|

|

|

|

||||

|

Model No.

|

Cummins 6B5.9-C130

|

Cummins 6BTA5.9-C170

|

Cummins 6BTA5.9-C180

|

Cummins 6BTA5.9-C205

|

||||

|

Rated power

|

97kw

|

127kw

|

132kw

|

155kw

|

||||

|

Rated speed

|

2200rpm

|

2200rpm

|

2200rpm

|

2200rpm

|

||||

|

Electrical system

|

24v

|

24v

|

24v

|

24v

|

||||

|

Starter

|

6.6KW/8.25HP

|

6.6KW/8.25HP

|

6.6KW/8.25HP

|

6.6KW/8.25HP

|

||||

|

Displacement

|

5.9L

|

5.9L

|

5.9L

|

5.9L

|

||||

|

CENERATOR

|

|

|

|

|

||||

|

Model No.

|

Stamford UCI224G

|

Stamford UCI274C

|

Stamford UCI274E

|

Stamford UCI274F

|

||||

|

Rated capacity

|

85KVA

|

100KVA

|

125KVA

|

160KVA

|

||||

|

Rated voltage

|

220V/380V

|

220V/380V

|

220V/380V

|

220V/380V

|

||||

|

Rated frequency

|

50Hz

|

50Hz

|

50Hz

|

50Hz

|

||||

|

HYDRAULIC SYSTEM

|

|

|

|

|

||||

|

Pump output-max

|

220 l/min

|

220 l/min

|

220 l/min

|

220 l/min

|

||||

|

Working pressure

|

29Mpa

|

29Mpa

|

29Mpa

|

29Mpa

|

||||

|

Crane pump output

|

35 l/min

|

35 l/min

|

35 l/min

|

90 l/min

|

||||

|

Working pressure

|

20Mpa

|

20Mpa

|

20Mpa

|

30Mpa

|

||||

|

CRANE

|

|

|

|

|

||||

|

Make

|

PALFINGER

|

PALFINGER

|

PALFINGER

|

PALFINGER

|

||||

|

Hoisting capacity

|

≤3200kgs

|

≤3200kgs

|

≤3200kgs

|

≤5000kgs

|

||||

|

Reach distance

|

≤5.6m

|

≤7.8m

|

≤7.8m

|

≤8m

|

||||

|

Rotary form

|

360 degrees

|

360 degrees

|

360 degrees

|

360 degrees

|

||||

Product Photos

Wincoo Engineering Co., Ltd (WINCOO) is engaged in bringing the most suitable solutions/equipments for client, fabricators, EPC/C companies on pipe fabrication, tank construction, pipeline construction,industrial production lines, clean energy project and other industrial field.

Our Services & Strength

We have ability of providing workable solutions to support clients to be awarded with shorter project execution time, fewer man-hour cost and higher efficiency construction/fabrication method and better quality during phase of project bidding.

Based client’s facility/site space availability, we are able to study/design and present matched configurations on project schedule, quality, cost and productivity to guarantee production pace is accordance with project requirement.

To support project execution, we are always ready to work as fireman to give prompt supply on project materials from different consumables, tools, equipments/machines to special merchandise. With flexibility, we are also glad to perform as procurement agent in China to seek required supply resources.

Our Services & Strength

We have ability of providing workable solutions to support clients to be awarded with shorter project execution time, fewer man-hour cost and higher efficiency construction/fabrication method and better quality during phase of project bidding.

Based client’s facility/site space availability, we are able to study/design and present matched configurations on project schedule, quality, cost and productivity to guarantee production pace is accordance with project requirement.

To support project execution, we are always ready to work as fireman to give prompt supply on project materials from different consumables, tools, equipments/machines to special merchandise. With flexibility, we are also glad to perform as procurement agent in China to seek required supply resources.

Hot Searches