- Product Details

- {{item.text}}

Quick Details

-

Product Name:

-

P80 Torch Plasma Cutter Cutting Consumables

-

Material:

-

Copper

-

Cutting Type:

-

Plasma Cuttting

-

Usage:

-

Plasma P80 Cutting Torch

-

Color:

-

Silvery

-

Welding type:

-

Plasma Cuting

-

Keyword:

-

Plasma Cutting Torch Consumables

-

Size:

-

Customized Size

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

XY

-

Model Number:

-

XYPLA-03

-

Product Name:

-

P80 Torch Plasma Cutter Cutting Consumables

-

Material:

-

Copper

-

Cutting Type:

-

Plasma Cuttting

-

Usage:

-

Plasma P80 Cutting Torch

-

Color:

-

Silvery

-

Welding type:

-

Plasma Cuting

-

Keyword:

-

Plasma Cutting Torch Consumables

-

Size:

-

Customized Size

Plasma cutter consumables are a set of components in your plasma cutter that gradually wear over time until they need to be replaced: they have a life cycle. The consumables are all found in the cutting torch itself, which is where most of the energy is focussed, and keeping track of wear and tear is a key part of maintaining an efficient machine that cuts well and lasts

SWIRL RING

This is a small component inside the torch that swirls the gas surrounding the plasma arc. This outer layer of gas helps to focus

a long time. Plasma cutting torch consumables include: a swirl ring, electrode, nozzle, retaining cap, and shield cap.

We can provide the Thand direct the arc for greater cutting precision, and swirling it helps to keep it cool. As it is this protective layer of gas surrounding the arc that makes contact with the nozzle, the lower temperatures prevent the nozzle from burning up, and slow down degradation.

ELECTRODE

The electrode is a narrow piece of copper containing hafnium (which is an excellent conductor of electricity). Its job is to receive the electrical current from a cathode block inside the torch to which it is connected, and to focus the charge through its tip, which causes it to arc onto the workpiece.

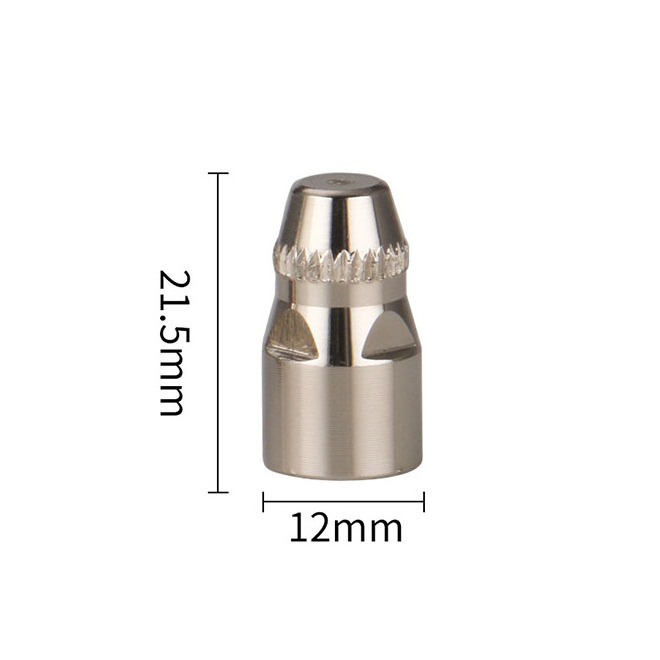

NOZZLE

The nozzle focuses the plasma arc and the gas that surrounds it to make a clean and precise cut. A nozzle with a larger opening is used for gouging, while a nozzle with a smaller opening is better able to direct the gas and so is used for fine, detailed work.

RETAINING CAP

The retaining cap essentially holds all of the consumable parts of the torch together. As temperatures at this end of the machine are extremely high, it’s not just the parts creating and focussing the arc that are worn down; the component holding them together also degrades over time.

SHIELD CAP

The shield is there to protect the torch and its other components from the sparks and molten metal that result from the plasma cutting process. It takes the brunt of the fallout so that wear to other components is minimised as much as possible.

| Hole Diameter | Available Current | Cutting Thickness |

| 1.1mm | 40A | 0-6MM |

| 1.3mm | 60A | 6-10MM |

|

1.5mm |

80A | 10-18MM |

| 1.7mm | 100A | 18-25MM |