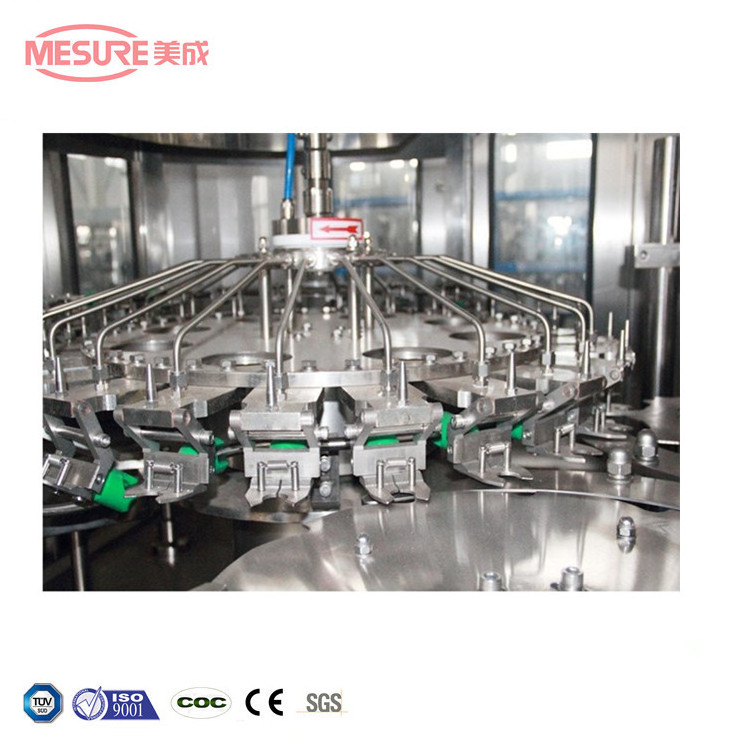

The bottle is blown into the bottle shifting wheel, when the flushing clamp reaches the bottle neck, the jaw will clamp the bottleneck, under the guidance of the rail, the clamp will turn the bottle 180° into an upright position, through second bottle pusher into the filling position.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

0.5%

-

Voltage:

-

220/380V 50Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Mesure

-

Dimension(L*W*H):

-

2200x2100x2200mm

-

Weight:

-

3~12T

-

Machine Material:

-

Stainless Steel 304/316

-

Control:

-

PLC+Touch Screen

-

Feature:

-

High Effective

-

Capacity:

-

2000-30000bph

-

Filling Valve:

-

High Speed Valve

-

Workshop Layout:

-

Free design

-

Bottle size:

-

200-2500ml (Customized)

-

Advantage:

-

20 years experiences factory

-

Filling Type:

-

Equal Pressure

-

Filling temperature:

-

3~5degree

-

Certification:

-

CE,ISO,SGS

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Beer, Water, Carbonated drink

-

Filling Accuracy:

-

0.5%

-

Voltage:

-

220/380V 50Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Mesure

-

Dimension(L*W*H):

-

2200x2100x2200mm

-

Weight:

-

3~12T

-

Machine Material:

-

Stainless Steel 304/316

-

Control:

-

PLC+Touch Screen

-

Feature:

-

High Effective

-

Capacity:

-

2000-30000bph

-

Filling Valve:

-

High Speed Valve

-

Workshop Layout:

-

Free design

-

Bottle size:

-

200-2500ml (Customized)

-

Advantage:

-

20 years experiences factory

-

Filling Type:

-

Equal Pressure

-

Filling temperature:

-

3~5degree

-

Certification:

-

CE,ISO,SGS

Product Application

1. The sparkling beverage filling equipment adopts bottle neck holding transmission technology to realize fully automatic rinsing, filling and capping. This 3-in-1 sparkling beverage filling machine is mainly used for PET bottled gas contained drinks such as soda drinks.

2. This carbonated-drinks filling machine adopts advanced PLC control technology. The main electric elements adopt Mitsubishi, Omron, Siemens, etc international famous products. Each machine element that contacts with the liquid is made of high-quality stainless steel.

|

Model

|

DCGN

18-18-6 |

DCGN

24-24-8 |

DCGN

32-32-10 |

DCGN

40-40-12 |

DCGN

50-50-15 |

DCGN

60-60-15 |

|||||

|

Production

Capacity

(500ml)

|

5000BPH

|

8000~

10000BPH

|

10000~

12000BPH

|

12000~

15000BPH

|

15000~

18000BPH

|

18000~

22000BPH

|

|||||

|

Suitable bottle height

|

H=170-320 Φ=50-100 |

|

|

|

|

|

|||||

|

Spraying pressure

|

0.25-0.3 |

|

|

|

|

|

|||||

|

Total Power

|

2.3

|

3.0

|

5.5

|

7.5

|

9.0

|

15

|

|||||

|

Overall dimension(L×W×H)

|

2500×

1760× 2650mm |

3100×

2100× 2650mm |

3800×

2800× 2650mm |

4000×

3300× 3400mm |

4850×

3650× 3300mm |

6500×

5400× 3500mm |

|||||

|

Weight

<kg> |

3500

|

4650

|

6800

|

8500

|

10000

|

12500

|

|||||

Main Features

1. This series of filling machines are used in production of PET bottled carbonated beverage, such as carbonated water, sprite and so on.

2. This series of products are the integrated rinsing, filling and capping machine, suitable for producing various PET bottled carbonated beverage.

3. The main machine adopts advanced PLC control technology.

4. The key electric elements adopt international famous products.

5. We will give you the highest quality and the best service.

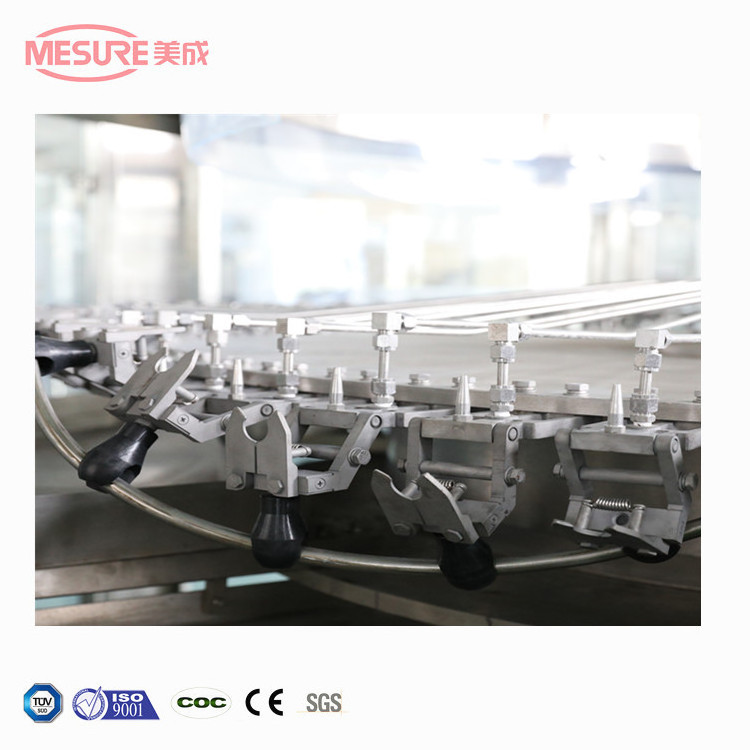

Washing Parts.

Filling Parts.

The filling part is manly composed of a filling valve and filling transmission parts. The washed bottle reaches the filling position via the bottle shifting wheel. In the meantime, the bottle clamping plate of the filling machine will clamp the bottle and move up to seal the bottle, filling valve will open, send the liquid into the bottle.

Sealing Parts.

Three capping heads are applied in model CGN18-18-6. The capping part consists of screw heads, capping transmission part, a sorting part and an undercover tube part. The bottle which has finished filling will enter the capping position via the driving wheel.

Main Features

World-Famous Brands:

Frequency inverter: MITSUBISHI (Japan).

PLC: MITSUBISHI (Japan), SIMENS (Germany)

Contactor: SIEMENS (Germany).

Breaker: SIEMENS (Germany).

Air switch: SCHNEIDER (France).

Blending System

Single layer, closed type, tapered bottom with dustproof breathing hole, high-speed blender, CIP ball sprayer, liquid level inspection, food-grade standard welding and polishing

Provide 24 hours Information Service

We will reply you at first time. And we have professional engineers can help you.

Pick you up to our factory

Welcome to our factory to have a visit, and we can pick you up from the airport or railway station.

Installation and commissioning

After the equipments arrived buyer's workshop, the buyer should take it's place for each equipment according to the supplied layout; the seller will send the experienced technician to guide the installation and debugging and trail production, and fulfil the designed capability within the designed time.

Training

The seller will supply technical training to the buyer. The training is includes: equipment structure and maintenance, control and operation. After training, the technicians of the buyer will grasp relevant operation and maintenance skills, and could adjust the technologies more skilled, and can deal with all kinds of malfunction in time.

After-sales service

1) After qualified of the equipment, the seller will supply one year guarantee, control system one year guarantee, free charge for wearing parts, and other spare parts with cost price. Within guarantee period, the technicians who accepted training should strictly obey the requirements asked by the seller to operate the equipments and maintenance, to find the common malfunctions and fault clearing in time; if the technicians of the buyer couldn't solve the problems themselves, the after-sales department will supply long range guide service by phone; if relevant measurements couldn't solve the problems, the seller will send the technicians to the buyer factory, clear the fault or relevant technical problems on site, the charges will reference to the installation and debugging charges.

2) After guaranteed, the seller will supply widely favorable technical support, after-sales service for the lifetime: favorable price for the wearing parts and other spare parts.

Company Instruction:

Located in Zhangjiagang City of Suzhou, the Yangtze River Delta, our company is covers an area of 6,000 square meters, with a more than 80 professionals team to design and develop, is a key professional enterprise, which integrates development, research, design, manufacture, technology service and marketing, to manufacture complete sets of wine, beverage and sticky filling equipments.

We are adhering to the principle of "market-oriented, quality as the main line, service as the guarantee and repute as the basis". MESURE follows international quality management system, it has established and improved the quality assurance system to ensure the quality and performance of the company's products. The Development department of MESURE, with advanced technologies, has more than 30 full-time design and development engineers. MESURE's technologies mainly sources from Italy, France, Germany, Switzerland and Japan; furthermore, a set of liquid filling production line with advanced technology and high starting-point has been developed combined with China's basic conditions, its high automation level achieved the one in late nineties. Department of After-sale Service of MESURE adheres to service goal of "Customers' needs are urgent, customers' requirements are important, customers' satisfaction is the aim", provides the services of equipment installation guidance, products testing, maintenance and spare-parts supplying, consultation, complaints, regular visit every 24 hours.

MESURE has a network for the complete set of beverage bottling lines for all over the world's end user, such as USA, Britain, Japan, the Middle East, Southeast Asia, Africa, Russia, CIS, South Africa etc. Besides the production and sale of equipments, MESURE provides various technical services to help users design equipment layout, answer users' consultation, train users' staff and provide practical operation guidance.