- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Raintech

-

Voltage:

-

220V/380V

-

Weight (KG):

-

1500

-

Product name:

-

Shearing Bending Punching Busbar Machine for Transfer Industry

-

Application:

-

Steel Structure

-

Keywords:

-

Busbar Machine Punching Molds

-

Processing material:

-

Copper Aluminum Bus Bar

-

Machine Type:

-

CNC Control

-

Package:

-

Wooden Case

-

Bending type:

-

CNC Control Busbar Machine

-

Color:

-

Customer's Requirement

Quick Details

-

Max. Thickness (mm):

-

15 mm

-

Max. Width (mm):

-

160 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Raintech

-

Voltage:

-

220V/380V

-

Weight (KG):

-

1500

-

Product name:

-

Shearing Bending Punching Busbar Machine for Transfer Industry

-

Application:

-

Steel Structure

-

Keywords:

-

Busbar Machine Punching Molds

-

Processing material:

-

Copper Aluminum Bus Bar

-

Machine Type:

-

CNC Control

-

Package:

-

Wooden Case

-

Bending type:

-

CNC Control Busbar Machine

-

Color:

-

Customer's Requirement

Multi-Functional Combined Busbar Processing Machine Busbar Turret Punching Bending Cutting Machine

Product Description

ZTMX series Bus bar punching bending shearing cutting embossing machine copper busbar machine

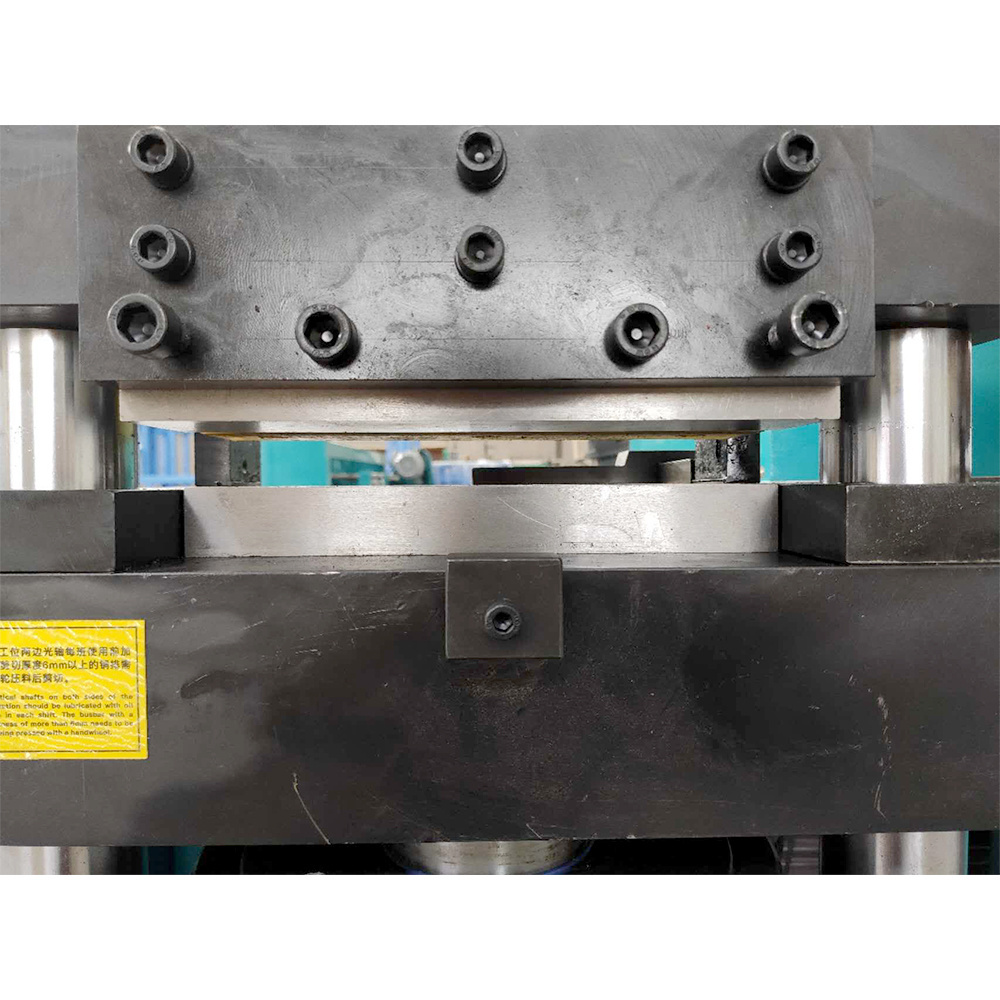

1. The shearing unit adopts the double column double knife shearing structure, the upper and lower knives are installed vertically and parallel to ensure a smooth cut, and no burr, no waste generation.

2.The punching unit adopts six die positions of integral turntable, (the turntable is an integrated processing parts, mold mounting holes for CNC machining center, high precision, mold and turntable with a clearance of 0.00-0.05mm), improve the concentricity of the mold, prolong the service life , in addition to the use of frequent replacement , improve efficiency.

3.The bending unit adopts closed bending, and the output point and the stress point are connected by a 50mm thick cross beam, which greatly enhances the mechanical strength compared with open bending.

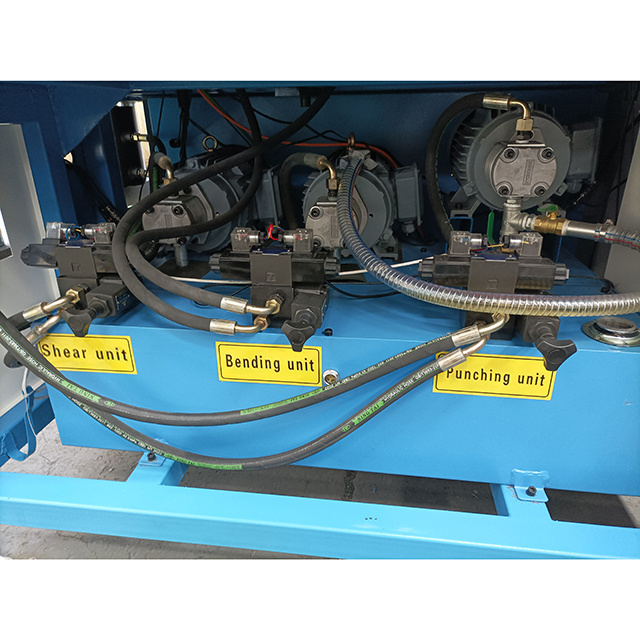

4.The three working stations of the machine can work simultaneously, which greatly improves the working efficiency.

5.The hydraulic oil tank is welded with thick steel plate and phosphate treatment, so that the hydraulic oil will not deteriorate in long-term use.

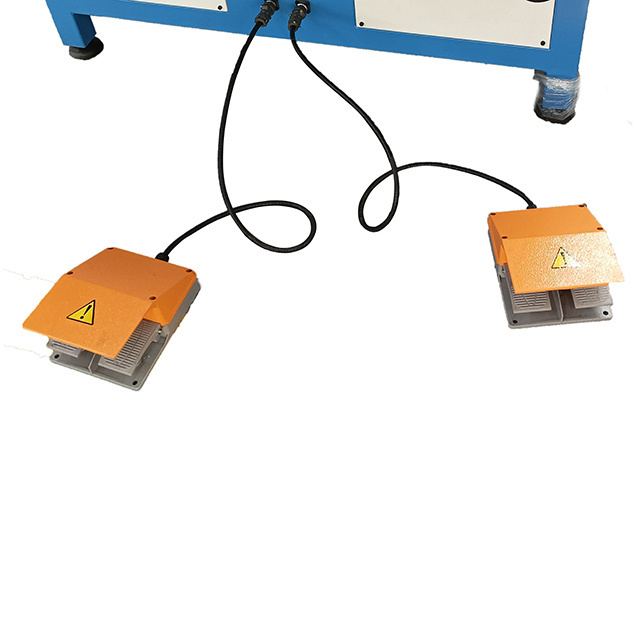

6.The three processing units of punching, shearing and bending are all controlled by a double foot pedal,In the case of automatic control mode, even if the upper and lower limits of each station are disconnected, it will never affect the user's production use, thus reducing the failure rate of the equipment and eliminating the safety hazards such as the rupture of the oil pipe of the pump that occurred in the past when the limit switch of the equipment failed. In the case of manual control mode, the operation of each station is simple and convenient, thus improving production efficiency.

7.This type of machine is divided into two models, ordinary type and CNC type, and the CNC system is a Taiwan product.

8.The equipment is equipped with a jacking and leveling device, easy to install.

DETAIL SHOW

Workpieces Show

Technical Parameter

|

Model

|

ZTMX-301

|

ZTMX-303

|

ZTMX-501

|

ZTMX-503

|

|

|

Max.punching force

|

350

|

350

|

500

|

500

|

|

|

Max.processing range

|

Φ4.3-φ35

|

Φ4.3-φ35

|

Φ4.3-φ36

|

Φ4.3-φ36

|

|

|

Max.punching thickness

|

12

|

12

|

18

|

18

|

|

|

Max. shearing thickness

|

12

|

12

|

18

|

18

|

|

|

Max.shearing width

|

160

|

160

|

260

|

260

|

|

|

Max. bending force

|

350

|

350

|

550

|

550

|

|

|

Max. bending width

|

160

|

160

|

260

|

260

|

|

|

Max.bending width into flat bend

|

16

|

16

|

20

|

20

|

|

|

Max.processing size of vertical bend

|

125*12

|

125*12

|

125*12

|

125*12

|

|

|

Main motor power

|

4

|

4(3 pcs)

|

5.5

|

5.5(3 pcs)

|

|

|

Machine weight approx.

|

1.2

|

1.4

|

1.8

|

2.2

|

|

|

Dimension

|

1800*1400*1300

|

1800*1400*1400

|

2000*1500*1400

|

2000*1500*1500

|

|

|

1 level worktable size

|

1770*1240

|

1770*1240

|

1840*1450

|

1840*1450

|

|

|

2 level worktable size

|

/

|

890*500

|

/

|

1000*500

|

|

|

Shearing,punching and bending work simultaneously

|

/

|

yes

|

/

|

yes

|

|

Packing&Shiping

Company Introducation

Exhibition

Feedback

FAQ

Hot Searches