- Product Details

- {{item.text}}

Quick Details

-

Materials:

-

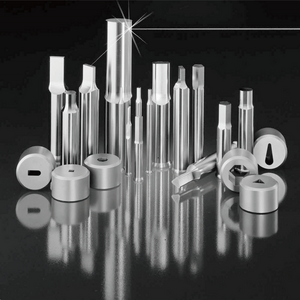

Tungsten Carbide for PUNCH PIN

-

Shape:

-

Customized PUNCH PIN / according to drawings

-

Grinding Precision:

-

0.02mm

-

Hardness:

-

According to the Material of PUNCH PIN

-

Standard:

-

DIN, ANSI, GB, ISO etc.

-

Surface:

-

Machined or Blank PUNCH PIN

-

Certification:

-

ISO9001:2008 PUNCH PIN

-

Use for:

-

Some special productions like hexagonal,square,flange nuts,tyre nuts

-

Grade:

-

YG3,YG6,YG6X.YG8.YG11.YG15.YG20.YG16C.YG18C. YG20C.YG22C. YG25C

Quick Details

-

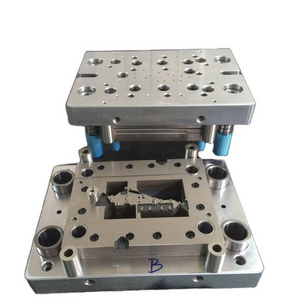

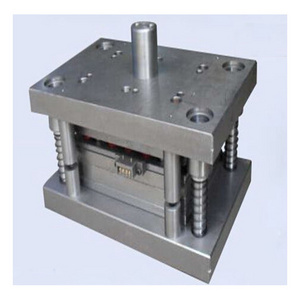

Shaping Mode:

-

Punching Mold

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

//

-

Materials:

-

Tungsten Carbide for PUNCH PIN

-

Shape:

-

Customized PUNCH PIN / according to drawings

-

Grinding Precision:

-

0.02mm

-

Hardness:

-

According to the Material of PUNCH PIN

-

Standard:

-

DIN, ANSI, GB, ISO etc.

-

Surface:

-

Machined or Blank PUNCH PIN

-

Certification:

-

ISO9001:2008 PUNCH PIN

-

Use for:

-

Some special productions like hexagonal,square,flange nuts,tyre nuts

-

Grade:

-

YG3,YG6,YG6X.YG8.YG11.YG15.YG20.YG16C.YG18C. YG20C.YG22C. YG25C

Products Description

HSS Punch

The material selection of the punch pin is mainly high-speed steel. The commonly used materials are SKH9, SKH55, SKH59 in Japan, M2, M35 and M42 in the United States. The main feature of the material is that the high-speed punching material can maintain good red hardness and wear resistance. There are also some powder high speed steel materials, commonly used are ASP23, ASP30, ASP60. The performance of the material is superior to that of high-speed steel, but the price is high and the range of use is relatively small. Tungsten carbide punch pins are new products that can be produced by a few companies this year. They are mainly made of tungsten carbide. They have high toughness requirements for materials, and the technical requirements and production costs during production are also high. They are commonly used in the stainless steel cold heading industry.

Material:

Carbide>M42(H59)>M35(H55)>M2(H9)

|

H9(M2)

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Chemical Composition

|

C

|

Si

|

Mn

|

P

|

S

|

Cr

|

Mo

|

V

|

W

|

|||||||||

|

Content (%)

|

0.85

|

0.33

|

0.34

|

0.027

|

0.005

|

4.12

|

4.73

|

1.78

|

5.74

|

|||||||||

|

|

Cu

|

Ni

|

|

|

|

|

|

|

|

|||||||||

|

|

0.12

|

0.24

|

|

|

|

|

|

|

|

|||||||||

|

M42(SKH59)

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Chemical Composition

|

C

|

Si

|

Mn

|

P

|

S

|

Cr

|

Mo

|

V

|

W

|

|||||||||

|

Content (%)

|

1.06

|

0.3

|

0.31

|

0.018

|

0.002

|

3.74

|

9.29

|

1.1

|

1.34

|

|||||||||

|

|

Cu

|

Ni

|

Co

|

|

|

|

|

|

|

|||||||||

|

|

0.07

|

0.29

|

7.97

|

|

|

|

|

|

|

|||||||||

Surface Treatment:

TILAN

|

Product Name:

|

HSS Pin Punch

|

|

Material:

|

M2/M42/M35/Carbide

|

|

Profile tolerance:

|

+/-0.006MM~ +/-0.008MM.

|

|

surface treatment:

|

Polishing,coating Treatment,Nitriding treatment,measuring,ETC..

|

|

Hardness

|

HRA60-68

|

|

Measuring instruments:

|

VMS,profile projector,pressure gauge,hardness tester,magnifying glass.etc...

|

|

Usage

|

For making bolts or nuts

|

|

Design:

|

Standard or un-standard parts,according to customer's requirement.

|

|

Processing machinery:

|

Wire EDM, CNC milling and turning, laser cutting, drilling, grinding, bending, stamping, welding, etc.

|

|

Drawing software:

|

AUTOCAD,pro-engineer,UG,moldflow,etc..

|

|

Application:

|

machinery equipment,Heavy industries parts&tools,medicine,chemical,etc...

|

|

Quality control:

|

100% inspection before shipping.

|

|

Customization:

|

OEM ODM service

|

Hot Searches