- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

LS3T-D, LS3T-D

-

Usage:

-

Multifunctional

-

Wire size:

-

Cu 1.00-3.25MM, Al 1.00-5.00MM

-

Material:

-

nodular cast iron

Quick Details

-

Use:

-

COLD WELDING

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SWAN, SWAN

-

Model Number:

-

LS3T-D, LS3T-D

-

Usage:

-

Multifunctional

-

Wire size:

-

Cu 1.00-3.25MM, Al 1.00-5.00MM

-

Material:

-

nodular cast iron

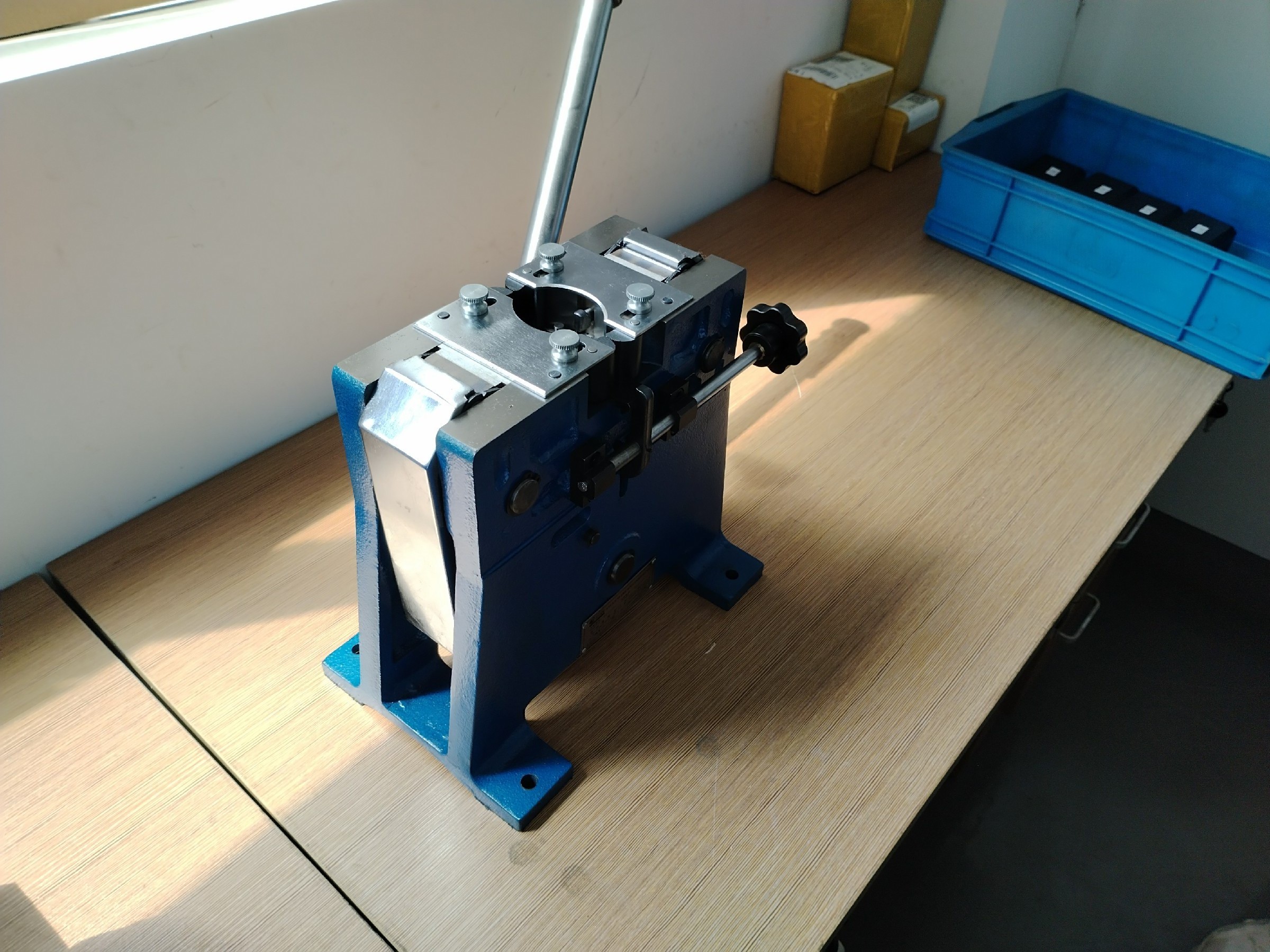

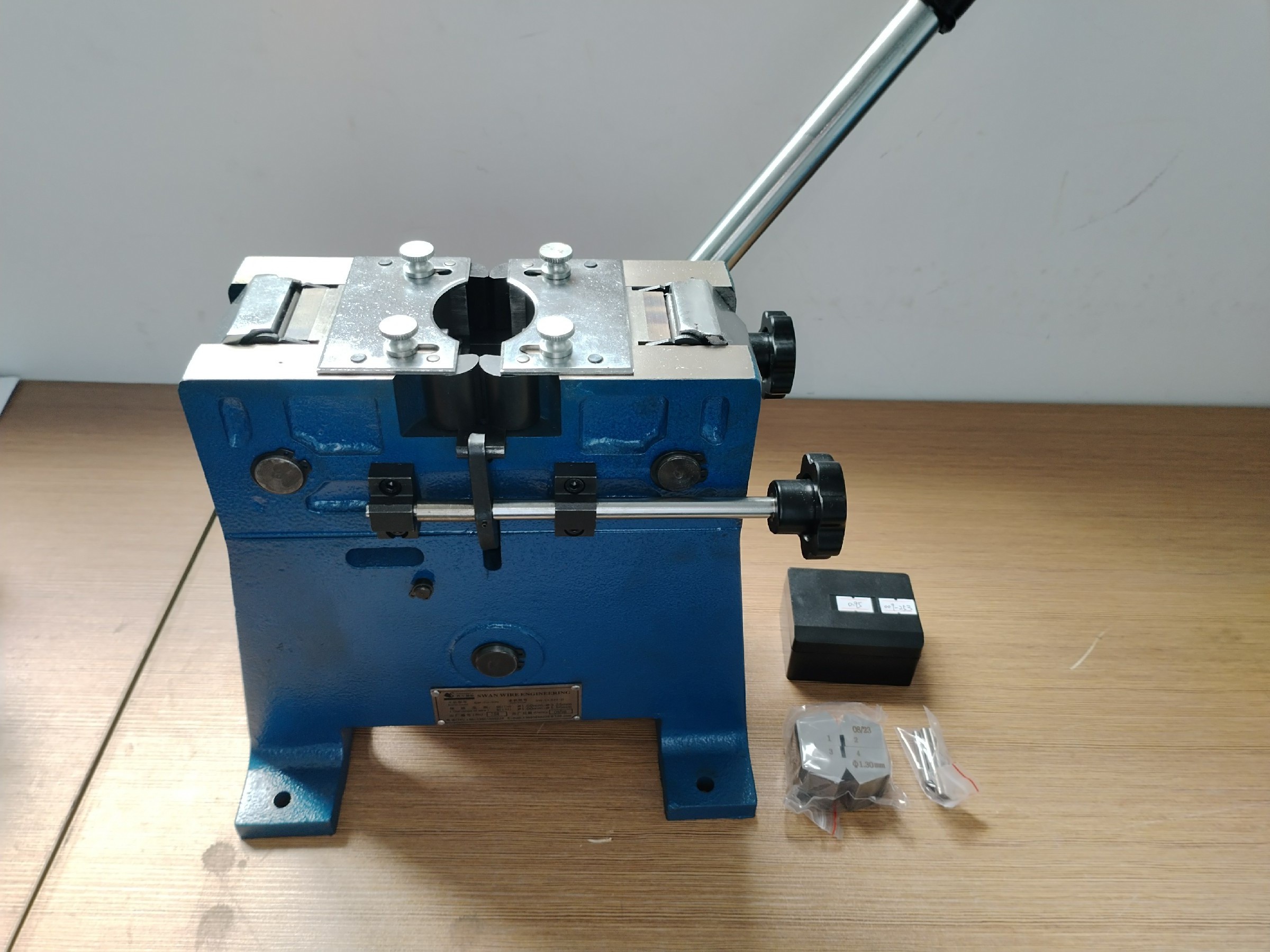

J3 Desktop Cold Welding Machine

Application

For Cu 1.00-3.25 mm Al 1.00-5.00 mm wire welding

Details Images

Product Description

J3 Desktop Cold Welding Machine

J3 cold welding machine

is one of our special products, the frame is made of 45# cast steel, the inner groove and plane on the second side of the upper body are finely ground by grinding machine, the main hole and rocker hole are machined by boring machine with high precision, the machine is mainly used for export or domestic large enterprises.

Finished Product

Related Product

|

Model

|

J0

|

J1

|

J2

|

J3

|

J5

(with 5.5KW)

|

|

Wire range for Cu(mm)

|

0.045-0.15

|

0.10-0.50

|

0.30-1.20

|

1.00-3.25

|

4.00-8.00

|

|

wire range for Al(mm)

|

0.07-0.15

|

0.10-0.50

|

0.30-1.40

|

1.00-5.00

|

4.00-15.00

|

|

Size(mm)

|

150*40*155

|

160*50*160

|

220*160*230

|

280*180*300

|

1190*570*1100

|

|

Weight(g)

|

500

|

650

|

1100

|

3300

|

650k

|

About cold welder(cold welding machine)

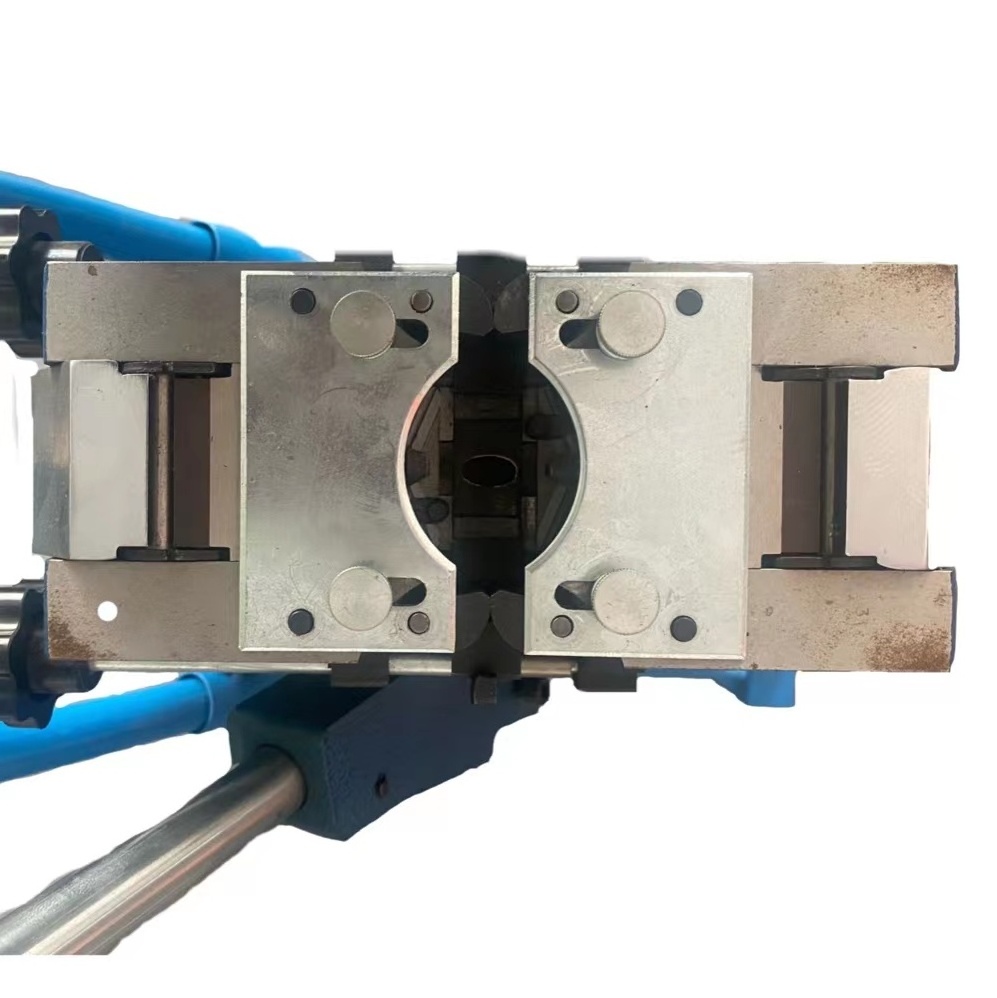

The cold welder is a tool to joint nonferrous wires with the method of cold butt weld,There is no need to use electricity,heat,flux and electrode,thus saving such troublesome preteating works of metal wire as cutting and cleaning the wire.

It only needs to thread two wire ends into a welding die,to match a suitable die depending upon the size of the wire,and then to press a handle of the welding machine several times,and the two wire ends get jointed.The result of such a welding is the same as the wire before welding,its tensile strength at the joint of the welded wire is good(equal to or even bigger than other wire)and is not broken at th joint.lts resistivity is not bigger than that of original wire ,therefore such welding is not to be compared with other welding method.

The merit of cold welding means simplicity in operation,with no need of extraordinary skill.With the method it is possible to ensure the reliability of welding,it is the most reliable and the most economic method to joint nonferrous wires and their allbys.

The merit of cold welding means simplicity in operation,with no need of extraordinary skill.With the method it is possible to ensure the reliability of welding,it is the most reliable and the most economic method to joint nonferrous wires and their allbys.

Hot Searches