- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V or 380 V or Customized

-

Dimension(L*W*H):

-

1150 x 850 x 850

-

Weight:

-

750 kg

-

Marketing Type:

-

New Product 2022

-

Application:

-

Fish Farm

-

Product name:

-

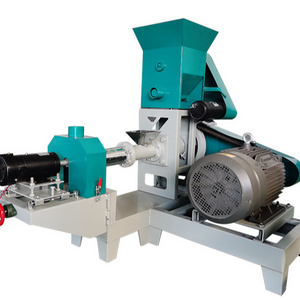

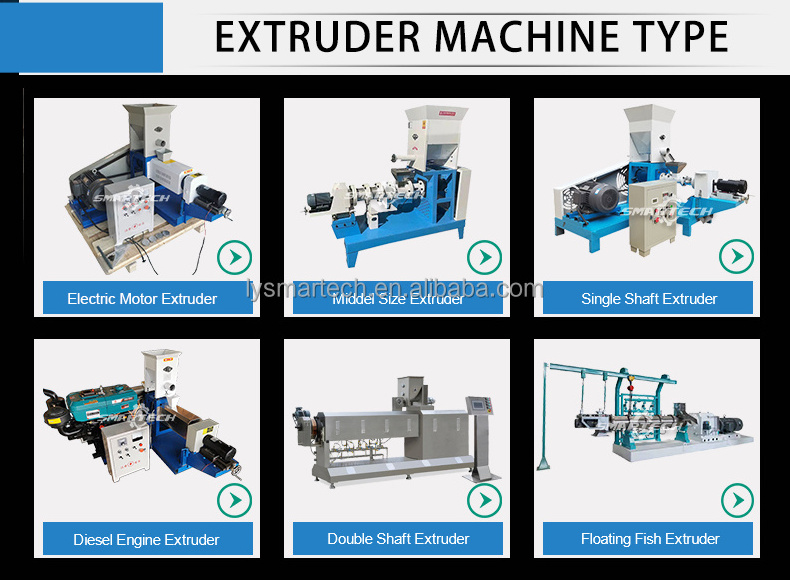

Fish Feed Extruder

-

Function:

-

Aniaml Feed Machine

-

Processing Types:

-

Screw Extrusion

-

Keywords:

-

Floating Fish Food Making Extruder Machine

-

Advantage:

-

Low Consumption

-

Suit for:

-

Fish.Dog.Cat

-

Material:

-

Durable Carbon Steel

-

Motor:

-

Siemens Brand

-

Driven Way:

-

Electric Motor Diesel Engine

Quick Details

-

Max. Capacity:

-

260-300 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Smartech

-

Voltage:

-

220V or 380 V or Customized

-

Dimension(L*W*H):

-

1150 x 850 x 850

-

Weight:

-

750 kg

-

Marketing Type:

-

New Product 2022

-

Application:

-

Fish Farm

-

Product name:

-

Fish Feed Extruder

-

Function:

-

Aniaml Feed Machine

-

Processing Types:

-

Screw Extrusion

-

Keywords:

-

Floating Fish Food Making Extruder Machine

-

Advantage:

-

Low Consumption

-

Suit for:

-

Fish.Dog.Cat

-

Material:

-

Durable Carbon Steel

-

Motor:

-

Siemens Brand

-

Driven Way:

-

Electric Motor Diesel Engine

300KGPH Floating Fish Extruder Food Processing Feed Plant for Animal Food

Products Details

1.

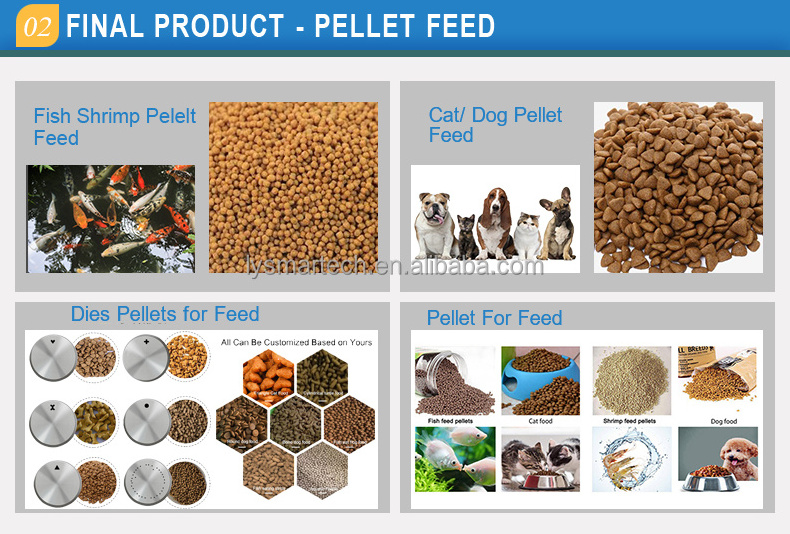

The floating fish feed pellet machine/fish food extruder can make kinds of feed for different fish, such as food fish, catfish, shrimps, crab, etc. the fish pellet made by the machine can float on water more than 24 hours.

2. The Floating-Feed Pellet Machine can make many kinds of fodder for different kinds of animal fodder. It can make poultry-fodder, pet-fodder, as well as aquaculture-fodder and fishery feed, which is also called floating –feed.

3. It is apply to the pretreatment of the animal fodder, so as to reduce loss of nutrition, advance the protein content so the fodder will be digested easier by animals.

4. The poultry-fodder can feed chicken, rabbit, sheep, pig, horse cattle and so on. The pet-fodder can feed dogs, cats, goldfish etc

2. The Floating-Feed Pellet Machine can make many kinds of fodder for different kinds of animal fodder. It can make poultry-fodder, pet-fodder, as well as aquaculture-fodder and fishery feed, which is also called floating –feed.

3. It is apply to the pretreatment of the animal fodder, so as to reduce loss of nutrition, advance the protein content so the fodder will be digested easier by animals.

4. The poultry-fodder can feed chicken, rabbit, sheep, pig, horse cattle and so on. The pet-fodder can feed dogs, cats, goldfish etc

5.

The Fishery-feed can feed the fish, shrimps, crab, eel , cat fish, and so on

Application of feed extruder for Fish or Pet Food

1. According to different requirements, variety shapes of high-grade feed pellets for fish, shrimps .etc

2. The finished pellets can keep floating for 12 hours without pollution to water.

3. The floating time can be controlled by the puffing degree adjustment

4. Floating feed extruder can make pellet from diameter 1mm-12mm through changing the mould.

5. Electric heating device is adopted which can improve the feed expansion rate and pellets floating time.

6. High temperature and high pressure cooking process can kill the salmonellosis and bacterial infections and also makes the pellets easily to digest.

7. The cutting device can be adjusted to make pellets of different length.

8. The wet type machine needs a boiler to make steam which can conduct steam to the conditioner and ripen the raw material in advance.

2. The finished pellets can keep floating for 12 hours without pollution to water.

3. The floating time can be controlled by the puffing degree adjustment

4. Floating feed extruder can make pellet from diameter 1mm-12mm through changing the mould.

5. Electric heating device is adopted which can improve the feed expansion rate and pellets floating time.

6. High temperature and high pressure cooking process can kill the salmonellosis and bacterial infections and also makes the pellets easily to digest.

7. The cutting device can be adjusted to make pellets of different length.

8. The wet type machine needs a boiler to make steam which can conduct steam to the conditioner and ripen the raw material in advance.

Technical Parameters

|

Model

|

Capacity

kg/h

|

Power

kw

|

Feeding Power

kw

|

Screw Diameter

mm

|

|

SPH-40

|

40-60

|

7.5

|

0.4

|

φ40

|

|

SPH-50

|

80-100

|

11

|

0.4

|

φ50

|

|

SPH-60

|

120-150

|

15

|

0.4

|

φ60

|

|

SPH-70

|

180-200

|

18.5

|

0.75

|

φ70

|

|

SPH-80

|

260-300

|

22

|

0.75

|

φ80

|

|

SPH-90

|

350-400

|

37

|

1.1

|

φ90

|

|

SPH-100

|

500-800

|

55

|

1.1

|

φ100

|

|

SPH-135

|

800-1000

|

75

|

1.1

|

φ135

|

|

SPH-160

|

1200-1500

|

90

|

1.5

|

φ160

|

|

SPH-200

|

1800-2000

|

132

|

1.5

|

φ200

|

Clients Reviews

Hot Searches