- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Stay Wires

-

Brand Name:

-

HUADONG CABLE

-

Popular Code Name::

-

Galvanized Steel Wire Strands Stay Wires

-

Certificate:

-

CE, CCC, ISO

-

MOQ:

-

1000m

-

Packing:

-

Wooden Drum, Iron Drum, with your request

-

Conductor Type:

-

Stranded

-

Production Experience:

-

Over 20 years

-

ACSR Cable Price:

-

Get the quotation within 12 hours

-

Material:

-

galvanized steel wire

-

Package:

-

Wooden Roll

Quick Details

-

Steel Grade:

-

galvanized steel wire

-

Type:

-

galvanized

-

Grade:

-

galvanized steel wire

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Stay Wires

-

Brand Name:

-

HUADONG CABLE

-

Popular Code Name::

-

Galvanized Steel Wire Strands Stay Wires

-

Certificate:

-

CE, CCC, ISO

-

MOQ:

-

1000m

-

Packing:

-

Wooden Drum, Iron Drum, with your request

-

Conductor Type:

-

Stranded

-

Production Experience:

-

Over 20 years

-

ACSR Cable Price:

-

Get the quotation within 12 hours

-

Material:

-

galvanized steel wire

-

Package:

-

Wooden Roll

Product Description

Stay Wires

are galvanized steel wire strands that are used for sustaining mechanical load. Generally they are made up of 6 wires stranded around 1 wire, twisting 7 wires together. A common use for stay wires is in the electricity industry, using the wire to stay power poles and tower structures. Stay wire is made in compliance with BS 183 or other customer specified specifications.

Material: The wire is cold drawn from steel and coated with zinc, the finish strand and the individual wires having uniform

quality and have the properties and product characteristics as specified in technical specification.

Construction: 7 Strand (6+1)

Specification: BS:183

Size: 7/1.60 to 7.40mm

Material: The wire is cold drawn from steel and coated with zinc, the finish strand and the individual wires having uniform

quality and have the properties and product characteristics as specified in technical specification.

Construction: 7 Strand (6+1)

Specification: BS:183

Size: 7/1.60 to 7.40mm

COIL SPECIFICATIONS:

|

Grade

|

Tensile Grade

|

Min. Tensile Strength

(N/mm2) |

|

1

|

1770

|

1770

|

|

2

|

1570

|

1570

|

|

3

|

1100

|

1100

|

|

4

|

700

|

700

|

|

5

|

450

|

450

|

|

Construction Number

of wires/wire diameter |

Approximate strand

diameter |

Minimum breaking load of strand

|

|

|

|

|

|

|

Approx.

mass |

||||||

|

|

|

Grade 350

|

Grade 480

|

Grade 700

|

Grade 850

|

Grade 1000

|

Grade 1150

|

Grade 1300

|

|

||||||

|

|

mm

|

KN

|

KN

|

KN

|

KN

|

KN

|

KN

|

KN

|

Kg/1000m

|

||||||

|

3/1.80

3/2.65 3/3.25 3/4.00 |

3.9

5.7 7.0 8.6 |

2.65

5.80 8.70 13.20 |

3.66

7.95 11.95 18.10 |

–

– – – |

–

– – – |

–

– – |

–

– – – |

–

– – |

60

130 195 295 |

||||||

|

4/1.80

4/2.65 4/3.25 4/4.00 |

4.4

6.4 7.9 9.7 |

3.55

7.70 11.60 17.60 |

4.90

10.60 15.90 24.10 |

–

– – 35.20 |

–

– – – |

–

– – – |

–

– – – |

–

– – – |

80

172 260 390 |

||||||

|

5/1.50

5/1.80 5/2.65 5/3.25 5/4.00 |

4.1

4.9 7.2 8.8 10.8 |

3.10

4.45 9.65 14.50 22.00 |

4.24

6.10 13.25 19.90 30.15 |

6.18

8.90 19.30 29.00 43.95 |

–

– – – – |

–

– – – – |

–

– – – – |

–

– – – – |

69

95 220 320 490 |

||||||

|

7/0.56

7/0.71 7/0.85 7/0.90 7/1.00 7/1.25 7/1.40 7/RS+ |

1.7

2.1 2.6 2.7 3.0 3.8 4.2 4.3 |

0.6

0.97 1.39 1.55 1.92 3.01 3.75 3.85 |

0.83

1.33 1.90 2.14 2.64 4.10 5.17 5.28 |

1.20

1.94 2.80 3.10 3.85 6.00 7.54 7.70 |

–

– – – – – 9.16 9.35 |

1.70

2.75 3.95 4.45 5.50 8.55 10.75 11.00 |

1.98

3.19 4.57 5.12 6.32 9.88 12.35 12.65 |

2.24

3.60 5.15 5.80 7.15 11.15 14.00 14.30 |

14

28 31 35 43 67 84 86 |

||||||

|

7/1.6

7/1.8 7/2.00 7/2.36 7/2.65 7/3.00 7/3.15 7/3.25 7/3.65 7/4.00 7/4.25 7/4.75 |

4.8

5.4 6.0 7.1 8.0 9.0 9.5 9.8 11.0 12.0 12.8 14.0 |

4.90

6.23 7.70 10.70 13.50 17.30 19.10 20.30 25.60 30.90 34.75 43.40 |

6.75

8.55 10.55 14.70 18.50 23.75 26.20 27.85 35.15 42.20 47.65 59.45 |

9.85

12.45 15.40 21.40 27.00 34.65 38.20 40.65 51.25 61.60 69.50 86.80 |

11.95

– – – – – – – – – – – |

14.10

17.80 22.00 30.60 38.60 49.50 54.55 58.05 73.25 88.00 99.30 124.0 |

16.20

20.50 25.30 35.20 44.40 56.90 62.75 66.80 84.20 101.0 114.0 142.7 |

18.30

23.20 38.60 39.80 50.20 64.30 70.90 75.50 95.20 114.0 129.0 161.3 |

110

140 170 240 300 392 430 460 570 690 780 970 |

||||||

|

19/1.00

19/1.25 19/1.40 19/1.60 19/2.00 19/2.50 19/3.00 19/3.55 19/4.00 19/4.75 |

5.0

6.3 7.0 8.0 10.0 12.5 15.0 17.8 20.0 23.8 |

5.22

8.16 10.24 13.37 20.90 32.65 47.00 65.80 83.55 117.85 |

7.16

11.19 14.04 18.34 28.65 44.80 64.50 90.27 114.6 161.6 |

10.45

16.32 20.47 26.75 41.78 65.29 94.00 131.6 167.1 235.7 |

–

– – – 50.74 79.28 114.1 159.9 203.0 286.0 |

14.92

23.32 29.25 38.20 59.69 93.27 134.3 188.0 283.7 336.7 |

17.16

26.81 33.64 43.93 68.64 107.3 154.5 216.3 274.6 387.2 |

19.40

30.31 38.02 49.66 77.60 121.3 174.6 244.5 310.4 437.7 |

120

180 230 300 470 730 1050 1470 1870 2630 |

||||||

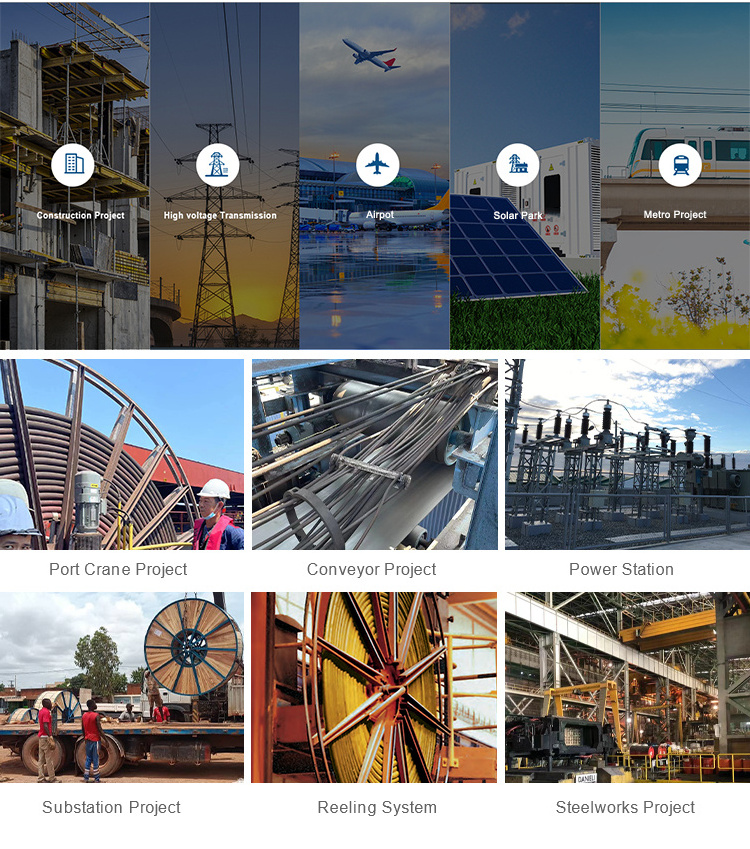

Customer Project

Certifications

Hot Searches