- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Siman

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

8 KG

-

Product name:

-

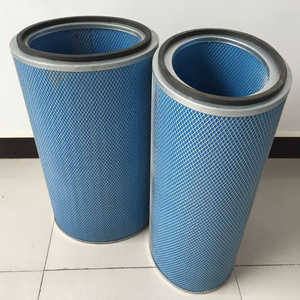

Drill Rig Engine Dust Collector Air Filter Cartridge

-

Name:

-

Air Filter Cartridge

-

Filtration Grade:

-

Hepa Filter

-

Certification:

-

EN779:2012,ISO/TS 16949:2009

-

Part Number:

-

P783648 A-8734 AF25772 86891509 88021199

-

material:

-

Cellulose

-

use in:

-

windy sand,moist climate environment

Quick Details

-

Efficiency:

-

99%, 99.99%

-

Porosity:

-

0.2

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Siman

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

8 KG

-

Product name:

-

Drill Rig Engine Dust Collector Air Filter Cartridge

-

Name:

-

Air Filter Cartridge

-

Filtration Grade:

-

Hepa Filter

-

Certification:

-

EN779:2012,ISO/TS 16949:2009

-

Part Number:

-

P783648 A-8734 AF25772 86891509 88021199

-

material:

-

Cellulose

-

use in:

-

windy sand,moist climate environment

Air Filter Cartridge

| Quick Details : | |

| Condition: | New |

| Efficiency: | 99.99% |

| Construction: | Cartridge Filter |

| Filtration Grade: | Hepa Filter |

| Medium Material: | Synthetic Fiber |

| Porosity: | Customized |

| Place of Origin: | Gu'an, China (Mainland) |

| Brand Name: | KL Filter |

| Model Number: | Customized |

| Dimension(L*W*H): | normal |

| Weight: | normal |

| Certification: | EN779:2012,ISO/TS 16949:2009 |

| Warranty: | one year |

| After-sales Service Provided: | No engineers available to service machinery overseas |

| description: | Air Intake Filter cartridge P954379 Dust Collector Air Filter P191177 |

| Service: | OEM/ODMDrill Rig Engine Dust Collector Air Filter Cartridge P500149 A-8734 AF25772 86891509 88021199 |

| material: | Cellulose |

| use in: | windy sand,moist climate environment |

| filtration efficiency: | High |

| Excellent ability: | moisture proof, water proof, Antiflaming |

| configuration: | Galvanized stainless metal,E-coating, Seepage zinc plate |

| seal: | Rubber seal |

| business type: | manufacturer,factory |

| Sam |

available

|

Filteration Classify:

Construction of gas turbine air filter:

Filter media – fully synthetic composite .

End caps – Electrostatic-Coating, Seepage zinc plate, Galvanized (ASTM A653, 60G TST, both sides) or stainless steel .

In / Outside Liner – Electrostatic-Coating, Seepage zinc plate, Galvanized (ASTM A653, 60G TST, both sides) or stainless steel .

Potting – Media shall be permanently and completely bonded to the end caps with Polyurethane or Plastisol or epoxy sealant.

Gasket – Seamless EPDM rubber (ethylene propylene diene monomer rubber - ASTM D1418) or molded in place urethane or polyisoprene sponge rubber .

Pleats are to be stabilized by hot-melt adhesive on both inner and outer cores.

Filters are to have polyester coalescing wrap (per-filter) pre-installed by the manufacturer .

Performance of gas turbine air filter:

Efficiency - F9. Minimum 99.9% (HEPA).

Hydrophobic (water proof), moisture proof, Antiflaming.

Salt Repellent – must remove 99.5% of all salt crystals from turbine inlet air.

Wet Burst Pressure – greater than 7500 Pa (30” wc).

Initial Pressure Drop – 180 Pa @ 2500 m3/h (.72” wc @ 1472 cfm).

Temperature Range - -40°C to +65°C (-40°F to +149°F).

Humidity Range – 0 to 100% relative humidity.

Flame Retardance – E d 2 according to EN 13501.

Must result in no (0%) Combustion Turbine Mega Watt power loss in 8000 hours of operation.

Must fit into air inlet systems without modification.

Manufacturing tolerances and joint details shall be such that no gaps or air/water leaks occur in the assembly after installation and during operation.

The performance of the filters is to match (or better) the below charts.

|

Operation Mode |

|

|

1 |

Pulse cleanable and static . |

|

2 |

Must last longer than one year of continuous service (8000 hours) . |

|

3 |

Operational environment – Marine, coastal, tropical and semi-tropical environments . |

Please click to learn more

Please click on the picture for more products