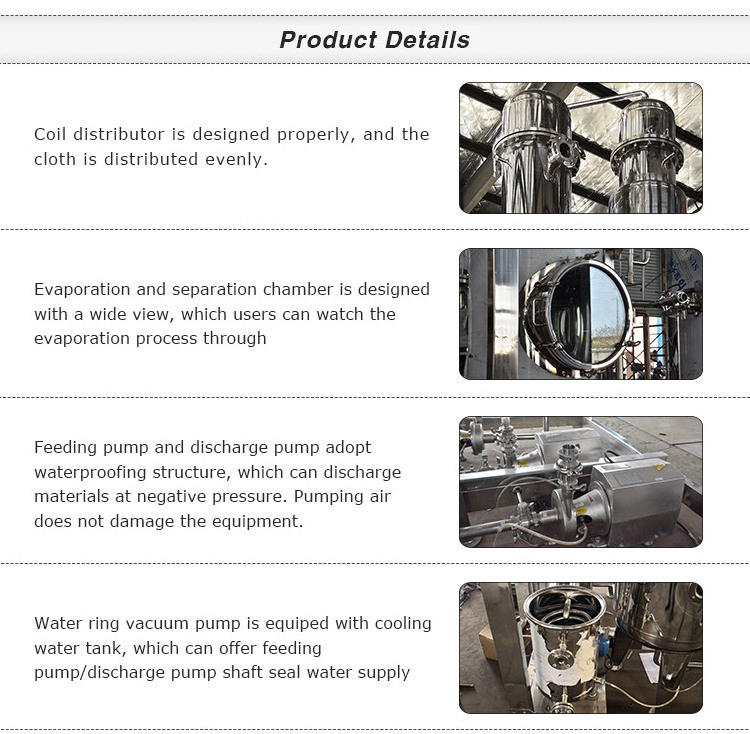

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

5.6kw

-

Dimension(L*W*H):

-

2100*1900*5000 mm

-

Weight:

-

2800 KG

-

Name:

-

single effect falling film

-

Evaporation speed:

-

200 L/H

-

Heating area:

-

12 Square meter

-

Condensing area:

-

16 Square meter

-

Style:

-

falling film evaporator stainless steel

-

Feeding pump:

-

1.5 kw

-

After Warranty Service:

-

Video technical support

-

Marketing Type:

-

Hot Product 2022

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Lanphan

-

Voltage:

-

380V/220V

-

Power:

-

5.6kw

-

Dimension(L*W*H):

-

2100*1900*5000 mm

-

Weight:

-

2800 KG

-

Name:

-

single effect falling film

-

Evaporation speed:

-

200 L/H

-

Heating area:

-

12 Square meter

-

Condensing area:

-

16 Square meter

-

Style:

-

falling film evaporator stainless steel

-

Feeding pump:

-

1.5 kw

-

After Warranty Service:

-

Video technical support

-

Marketing Type:

-

Hot Product 2022

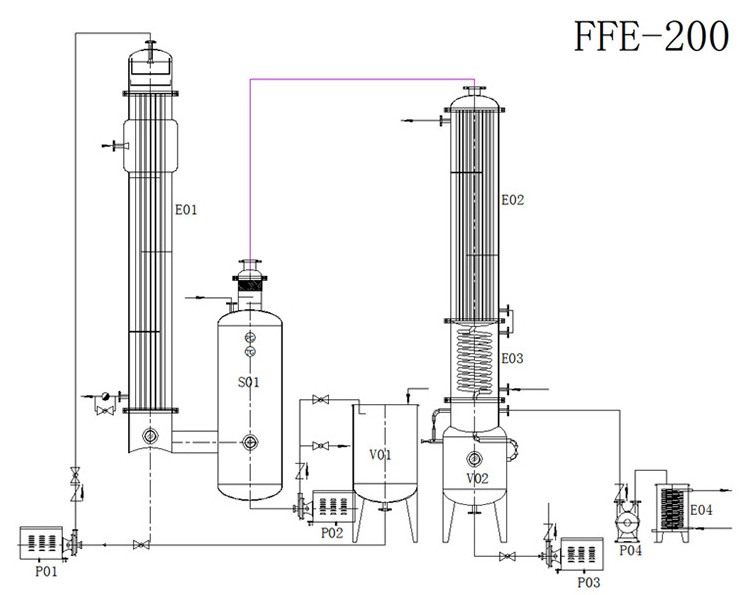

The function of single-effect falling film evaporator is to separate the ethanol from material and condense and recover it through reduced pressure vacuum and evaporation. The single-effect falling film evaporator used for ethanol solution production is different from the general single-effect falling film evaporator used for aqueous solution production. Ethanol has a low boiling point and is volatile. Ethanol can be evaporated easily under vacuum and reduced pressure, so it has a small evaporation area. It is difficult to condense and recover ethanol vapor, so the heat exchange area of the condenser is relatively large. In order to obtain a good cooling effect, two or more stages are often used for cooling recovery, which is also different from the general aqueous solution evaporation.

Theory of falling film evaporation

The materials are evenly distributed into each falling film pipe through the distributor, and flow down the wall of the pipe in the state of a liquid film. Under the action of gravity and the secondary steam flow, the materials get evaporated while flowing down. At the bottom of the falling film tube, the materials and secondary steam are basically separated, and they reach the separation chamber to achieve complete separation.

S01——Evaporation and separation chamber

E01——Tube heater E02——Tube condenser

E03——Coil condenser E04——Vacuum pump cooler

V01——Middle tank V02——Ethanol collection tank

P01——Feeding pump P02——Concentrate discharge pump

P03——Discharge pump of ethanol P04——Water ring vacuum pump

Working process of falling film evaporator

Feeding(V01) - evaporation(E01) - separation(S01) - condensation(E02) - cooling (E03) - storage tank (V02)

Features of falling film evaporator

1. Low heating temperature

2. High evaporation speed

3. Short liquid residence time

4. Continuously feeding and discharging

5. Suitable for heat sensitive materials

6. Energy-saving

| Model | FFE-20 | FFE-50 | FFE-100 | FFE-200 | FFE-500 | FFE-1000 |

| Evaporation speed | 20 | 50 | 100 | 200 | 500 | 1000 |

| Heating area | 1.2 | 3 | 5 | 12 | 25 | 50 |

| Condensing area | 1.5 | 5 | 7.5 | 16 | 30 | 60 |

| Feeding pump | 0.55 | 0.55 | 1.1 | 1.5 | 1.5 | 1.5 |

| Discharge pump 1 | 0.55 | 0.55 | 1.1 | 1.5 | 1.5 | 1.5 |

| Discharge pump 2 | 0.55 | 0.55 | 1.1 | 1.1 | 1.5 | 1.5 |

| Water ring vacuum pump | 0.75 | 0.81 | 0.81 | 1.5 | 2.2 | 3.85 |

| Power | 2.4 | 2.46 | 4.11 | 5.6 | 6.7 | 8.35 |

| Power supply | 220V/60Hz Three-phase power,Other component could be customized | |||||

single effect falling film applications

Single-effect falling film evaporator is widely used in food, dairy, chemical, biological engineering, environmental protection engineering and corn deep processing, such as for aqueous solutions, organic solvent solutions, fruit and vegetable juices, milk, eggs, vitamin C, collagen , Tea immersion liquid, sodium glutamate and other evaporative concentration. It is especially suitable for evaporative concentration of heat-sensitive materials, and the beneficial elements of the material can be protected to the greatest extent during the heating and evaporation process.