- Product Details

- {{item.text}}

Quick Details

-

Depth of the Barrel:

-

2000mm

-

Effective volume:

-

5.46 cubic metre

-

Stirrer dia.:

-

550mm

-

Stirrer rotating speed:

-

230 r/min

-

Motor power:

-

5.5 kw

-

Weight:

-

1671 kg

-

Type:

-

Mixing Agitator Tank , Agitation Barrel

-

Function:

-

Mining mineral Agitator Mixing Barrel

Quick Details

-

Place of Origin:

-

Henan, China

-

Name:

-

China Mining Mixing Agitatortank Gold Leaching Barrel

-

Barrel inside dia.:

-

2000mm

-

Depth of the Barrel:

-

2000mm

-

Effective volume:

-

5.46 cubic metre

-

Stirrer dia.:

-

550mm

-

Stirrer rotating speed:

-

230 r/min

-

Motor power:

-

5.5 kw

-

Weight:

-

1671 kg

-

Type:

-

Mixing Agitator Tank , Agitation Barrel

-

Function:

-

Mining mineral Agitator Mixing Barrel

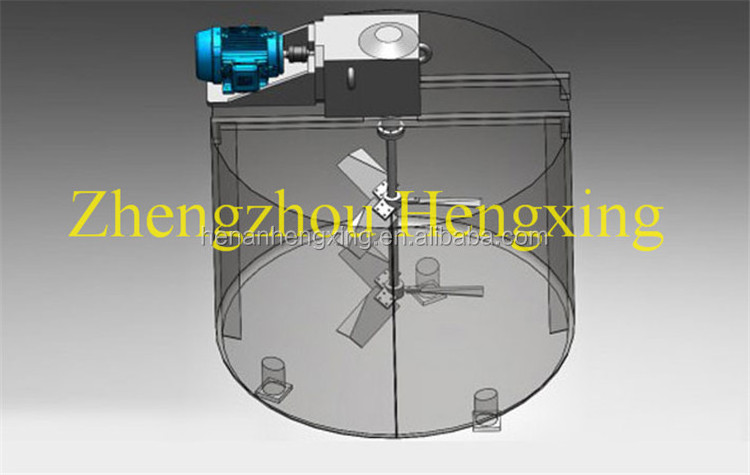

Stainless Steel Agitator Slurry Tank,

Mixing Machine, Agitation Tank Equipment For Mixing Mining

Introduction Of China Mining Mixing Agitatortank Gold Leaching Barrel

The stirring tank, also named stirring tub, is indispensable equipment in flotation process. According to utility, there are pulp mixing tank, elevating mixing tank and medicament stirring tank respectively.

The stirring tank is mainly used for pulp stirring before the flotation process. It makes ore grains suspend and fully contact and mix with medicament, creating conditions for flotation.

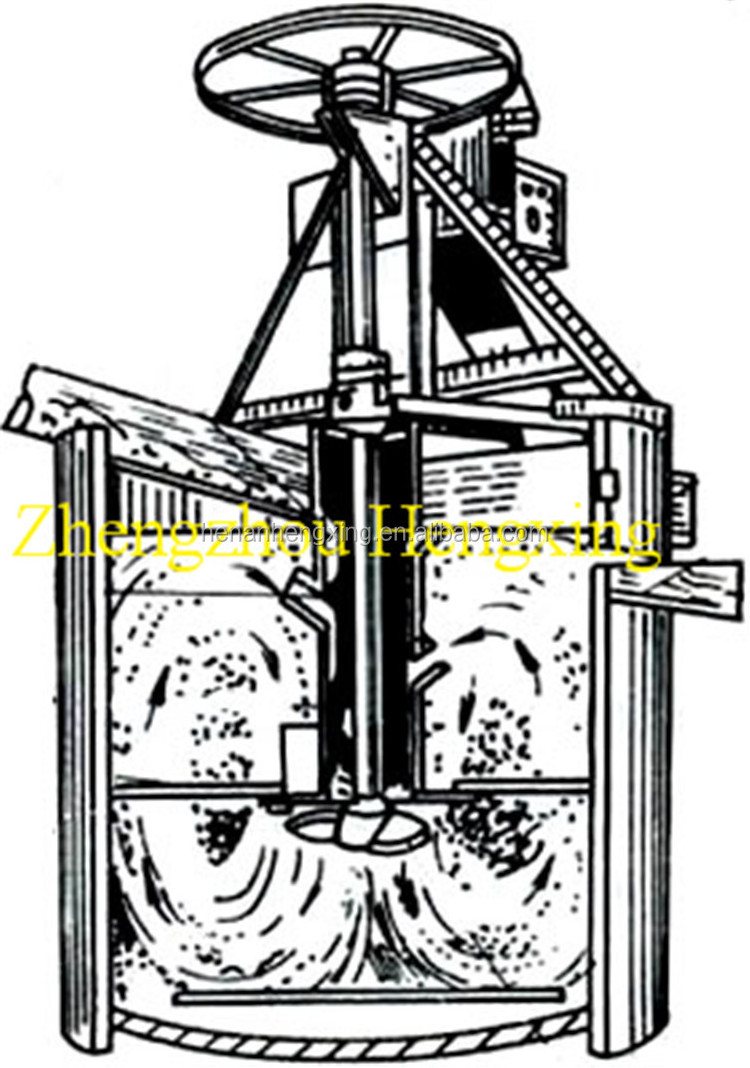

The main components: mixing trough, shaft, the motor, transmission device, support and baffle. The stirring tank rotates with the mixing wheel to realize material mixing in the slot.

Application of China Mining Mixing Agitatortank Gold Leaching Barrel

This kind of equipment is used in dissolution of the medication and the pretreatment of the mixing of the ore slurry. It can be also used in some industrial department such as the chemistry, slurry in the construction, cyanogens factory and waste-water factory and coal dressing factory.

Features of China Mining Mixing Agitatortank Gold Leaching Barrel

This kind of equipment is used in dissolution of the medication and the pretreatment of the mixing of the ore slurry. It can be also used in some industrial department such as the chemistry, slurry in the construction, cyanogens factory and waste-water factory and coal dressing factory. The leaching tank mainly uses charcoal immersing method and ore slurry resin method to produce gold. We can put active charcoal or resin into the mixer to get the immersed gold by mixing the whole materials.

This machine rotate by the V-belt drives the impeller; make medicine and mash mix even enough, increase the medicine effect time, strength the medicine effect quality, necessary set. It fits concentrating, and every chemical industry mixing.

Instruction Of China Mining Mixing Agitatortank Gold Leaching Barrel

1. Tighten the pump body bolts, check whether the rotating shaft is flexible and then start running mixer and flotation machine;

2. Wearing parts: impeller, the stator;

3. Mixer and automatic feeder must be clean, especially in winter, which can extend the service life.

Parameters Of China Mining Mixing Agitatortank Gold Leaching Barrel

|

Internal

|

Height

|

Volume

|

Impeller

|

Impeller

|

Weight

|

Power

|

Dimension

|

|

|

XB-500 |

500 |

500 |

0.098 |

600 |

200 |

0.15 |

1.1 |

600×566×954 |

|

XB-750 |

750 |

750 |

0.26 |

530 |

240 |

0.23 |

1.5 |

1131×880×1241 |

|

XB-1000 |

1000 |

1000 |

0.58 |

530 |

240 |

0.44 |

1.5 |

1131×1130×1492 |

|

XB-1200 |

1200 |

1200 |

1.14 |

320 |

400 |

0.76 |

3 |

1500×1480×1800 |

|

XB-1500 |

1500 |

1500 |

2.2 |

320 |

400 |

1.1 |

3 |

1750×1640×2190 |

|

XB-2000 |

2000 |

2000 |

5.46 |

230 |

550 |

1.67 |

5.5 |

2380×2162×2850 |

|

XB-2500 |

2500 |

2500 |

11.2 |

200 |

650 |

3.44 |

11 |

3036×2716×3543 |

|

XB-3000 |

3000 |

3000 |

19.1 |

210 |

700 |

4.61 |

18.5 |

3604×3216×4250 |

|

XB-3500 |

3500 |

3500 |

30 |

230 |

850 |

7.11 |

22 |

3940×3766×5386 |

Our mission is providing our clients timely, rapidly, and efficiently services.

√ Rapid Reply

To the issue you propose, or the feedback, we are sure to make reply soon.

√ Providing Solution Design:

According to the results of communication with you, we will provide a design solution for you speedly.

√ Inspection Our Factory and Machines:

If you have interests, welcome to visit our factory and inspect the machine.

√ Order execution:

Provide equipment layout draw, foundation draw and detailed equipment manauls. Timely report you the manufacturing schedule and related photos.

√ Delivery fast:

We can arrange fast, safe shippment on time.

√ After-sales service:

If you need, we will dispatch engineer to the site to guide installation, debugging and training operators. Installation and operation workers are offered if you need.