- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

4000 r.p.m

-

Spindle Bore(mm):

-

35

-

Width of bed (mm):

-

30 mm

-

Spindle Motor Power(kW):

-

3.7KW

-

Max. Turned Length (mm):

-

250

-

Travel (X Axis)(mm):

-

700 mm

-

Travel (Z Axis)(mm):

-

250 mm

-

Place of Origin:

-

Guangdong, China

-

Dimension(L*W*H):

-

1780mm*1400mm*1550mm

-

Brand Name:

-

WEIKONG

-

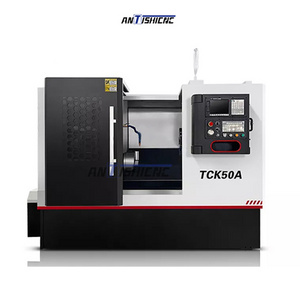

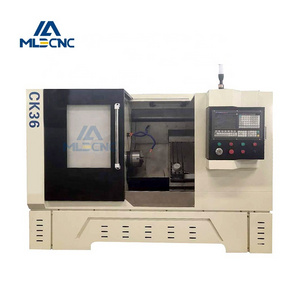

Model Number:

-

CL36B005

-

Voltage:

-

380V

-

Weight (KG):

-

1600

-

Marketing Type:

-

Hot Product 2023

-

CNC or Not:

-

CNC

-

Collet Type:

-

Hydraulic Collet

-

Spindle Nose Taper:

-

A2-4

-

Z/X Axis:

-

Up to 25m/min

-

Machine type:

-

CNC lathe

-

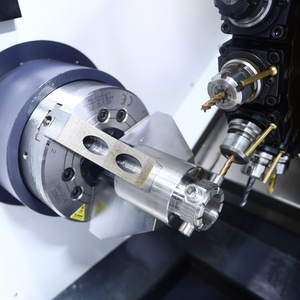

function:

-

Metal Turning

-

Safety:

-

Fully-guarded Machine

-

Outer diameter of cutting tool shank:

-

16mm*16mm

-

Keyword:

-

Automatic CNC Lathe Machine

-

Control system:

-

Similar Syntec Cnc Controller

Quick Details

-

Type:

-

Horizontal

-

Max. Length of Workpiece (mm):

-

200

-

Year:

-

2023

-

Max. Spindle Speed (r.p.m):

-

4000 r.p.m

-

Spindle Bore(mm):

-

35

-

Width of bed (mm):

-

30 mm

-

Spindle Motor Power(kW):

-

3.7KW

-

Max. Turned Length (mm):

-

250

-

Travel (X Axis)(mm):

-

700 mm

-

Travel (Z Axis)(mm):

-

250 mm

-

Place of Origin:

-

Guangdong, China

-

Dimension(L*W*H):

-

1780mm*1400mm*1550mm

-

Brand Name:

-

WEIKONG

-

Model Number:

-

CL36B005

-

Voltage:

-

380V

-

Weight (KG):

-

1600

-

Marketing Type:

-

Hot Product 2023

-

CNC or Not:

-

CNC

-

Collet Type:

-

Hydraulic Collet

-

Spindle Nose Taper:

-

A2-4

-

Z/X Axis:

-

Up to 25m/min

-

Machine type:

-

CNC lathe

-

function:

-

Metal Turning

-

Safety:

-

Fully-guarded Machine

-

Outer diameter of cutting tool shank:

-

16mm*16mm

-

Keyword:

-

Automatic CNC Lathe Machine

-

Control system:

-

Similar Syntec Cnc Controller

Standard Configuration

|

Fully protected integral casting base

|

3.7KW spindle servo motor

|

Telescopic guards for X/Z axes

|

|

|

||

|

Spindle speed 4000 rpm, A2-4

|

Automatic lubrication system

|

Coolant system

|

|

|

||

|

Lubrication system

|

Hydraulic system

|

Coolant tank

|

|

|

||

|

Oil separator

|

LED working lamp

|

Electronic handwheel (MPG)

|

|

|

||

|

Coolant gun

|

Toolbox and user manuals

|

The tool holder(5 Sets)

|

|

|

||

|

Collet (1 Set)

|

C axis

|

CNC Simulation

|

|

|

||

Features

WHY choose WKTEC Lathe

Brief Overview

1. We are a company specializing in the manufacture of CNC systems, turning and milling machine machines, and industrial robots.Since its establishment, we have more than 19 years of experience, and we have successfully exported our products to all countries in the world. Our company is committed to providing high-quality, high-performance machinery and equipment to meet the needs of customers.

2. As a technology company, our products cover the fields of CNC systems, mini CNC turning machines, turning and milling machines, and industrial robots. We use state-of-the-art technology and innovative design concepts to continuously push the industry forward. Our team consists of a group of experienced and skilled engineers and experts with in-depth knowledge and expertise in the field of mechanical engineering and automation.

Advantages of our company

1) High-quality products: We are committed to providing high-quality machinery and equipment, using advanced manufacturing technology and strict quality control to ensure the reliability and stability of products. Our products are rigorously tested and quality verified to ensure compliance with the highest industry standards.

2) Technological innovation: We continue to pursue technological innovation and research and development, leading the development trend of the industry. We work with research institutes and partners to research and develop new technology applications to provide customers with more efficient and intelligent solutions.

3) Customer customization: We fully understand the unique needs of each customer and provide customized solutions. Our team of engineers works closely with our customers to ensure that our products and services meet their specific requirements and provide the best solutions.

4) Global market expansion: We have successfully exported our products to all countries in the world, and established an extensive international sales network. We have an in-depth understanding of the needs and trends of each market and provide our customers with global support and services.

5) After-sales service: We attach importance to long-term cooperative relations with customers, and provide comprehensive after-sales service and technical support. Our after-sales team is always ready to answer customers' questions and provide training and maintenance support to ensure customer satisfaction and the normal operation of equipment.

FAQ

1:How can I choose machines?

A: for the model selection, please send us the drawing of the turning part and our engineer will evaluate it and provide the suitable configuration of the CNC lathe fit for your needs.

2:Our strengths?

WKTEC is a CNC system manufacturer with 19 years of experience, mastering core technologies. Currently producing CNC lathes to better serve customers

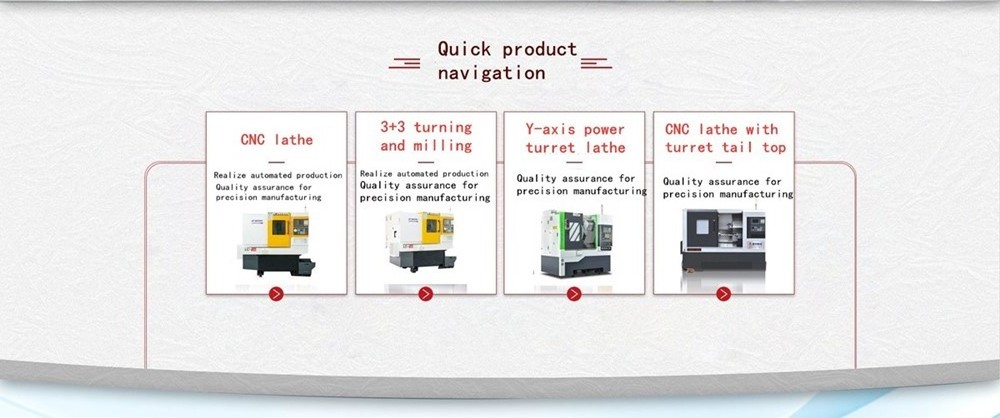

3: What's the main products of your company?

A: WKTEC Lathe concentrated all its resources to develop successfully theLC series of the CNC slant bed lathes ,Development of CNC controller,Development of CNC lathe systems, CNC milling machine systems, customized CNC systems, etc。including the LC-07, LC-25, LC-36, LC-46, and the CNC Turning-Milling machines to help our customers in the field of prototyping, entry-level business, and the craftsman with a bootstrap budget.

4: Where is our factory located? How can I visit there?

A: Our factory is located in Foshan City, Guangdong Province, 528300 China. You are warmly welcome to visit our factory.

5: What are the Trade & Payment Terms?

A: FOB, CFR, and CIF are all acceptable. T/T,30% initial payment when order,70% balance payment before shipment; Irrevocable LC at sight.

6: What's the MOQ?

A: 1 set. We will offer you’re a better price if you order more.

7. What is the delivery time?

A: The full series of standard models are in stock. For a customized one, it depends.

8. What is the warranty period?

A: The warranty period is generally 13 months after B/L date.

9. Machine installation

A: WKTEC LATHE could assign the technician to the place for the on-site installation if requested by the purchaser.

10. Technical Support

A: The technical response is available within 12 hours while the solution for the troubleshooting is provided within 48 hours.

11. Demo and Testing

A: WKTEC LATHE built a training center for the clients and employees to study the operation of the machine. You are welcome to visit our factory anytime for the machines’ demo. Furthermore, we could demo per your drawing of turning parts.

12. What is the form of after-sales service?

-a.Warranty is one year(Just for parts).There is no visiting reparing,We offer video support and send the parts for repairing.

-b.Sample making shall be conducted before order if required, i.e. the buyer shall pay the sample making fees first.

-c. Manufcturer shall do the testing and commisioning for the goods before shipment.

-d.After shipment, buyer can go to local maintenance if technical issues occured (Manufacturer will be responsible for sending spare parts if buyer need. )

-e.Spare parts such as belt, chuck, screw & nuts, hydraulic oil, working lighting, cutting tool, etc are not under warranty scope.

Hot Searches