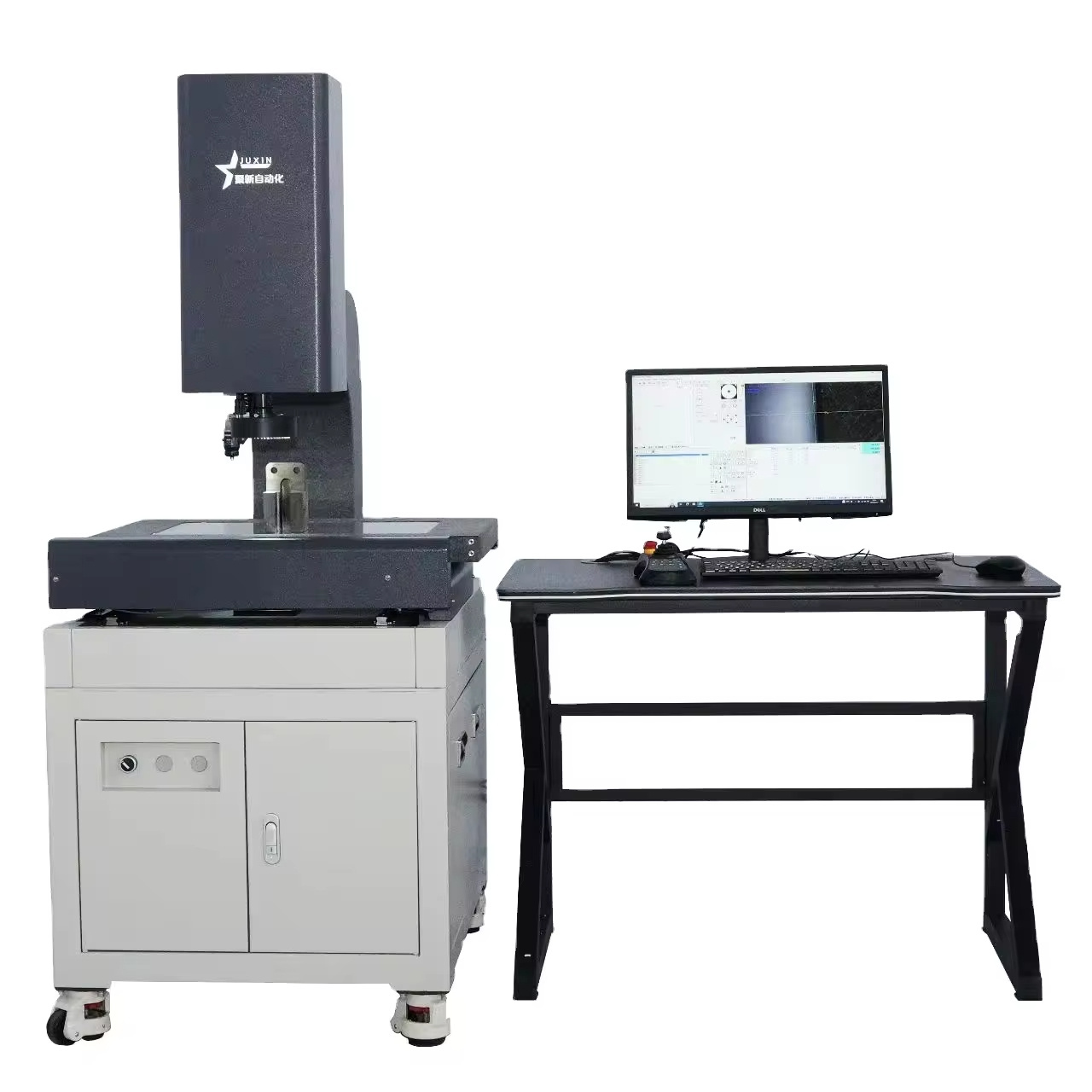

1.Granite base and column ,with strong rigidity ,small deformation,high accuracy,and good stability.

2.Adapting Taiwan precision guide screw,three-axis fully closed-loop servo control.

3.The three-axis adopts high-precision linear guide rails from Taiwan to ensure machine accuracy and service life.

4.High definition digital industrial camera ,achieving high-definition precision measurement of products and z-axis optical height measurement.

5.Can import and export DXF files,compare drawing with physical inspection results.

6.Measurement data can be quickly exported to Word,Excel Auto CAD,and can be quickly photographed.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

BES GEAR

-

Model Number:

-

AVS-3020 (G)

-

Material:

-

Granite base and columns, Marble base

-

Size:

-

1300*800*1700

-

Function:

-

3D automatic size detection

-

Raster scale resolution:

-

0.5

-

Measurement accuracy:

-

3.0+L/200

-

Detection type:

-

Full inspection and spot check

-

Model:

-

AVS-3020 (G)

-

Battery:

-

AC220±10% 50Hz

-

Power:

-

220V

Quick Details

-

Warranty:

-

1 year

-

Type:

-

3D automatic dimension measurement

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

BES GEAR

-

Model Number:

-

AVS-3020 (G)

-

Material:

-

Granite base and columns, Marble base

-

Size:

-

1300*800*1700

-

Function:

-

3D automatic size detection

-

Raster scale resolution:

-

0.5

-

Measurement accuracy:

-

3.0+L/200

-

Detection type:

-

Full inspection and spot check

-

Model:

-

AVS-3020 (G)

-

Battery:

-

AC220±10% 50Hz

-

Power:

-

220V

Product Overview

AVS-3020 (G)

This series is a manual optical image measuring instrument that combines traditional optical and imaging technologies and is equipped with corresponding measurement software. It is easy to operate and provides convenience for measuring products with small batches, diverse types, and complex shapes. It is widely used in industries such as

mechanical processing, precision electronics, mold manufacturing, rubber and plastic, and hardware parts.

mechanical processing, precision electronics, mold manufacturing, rubber and plastic, and hardware parts.

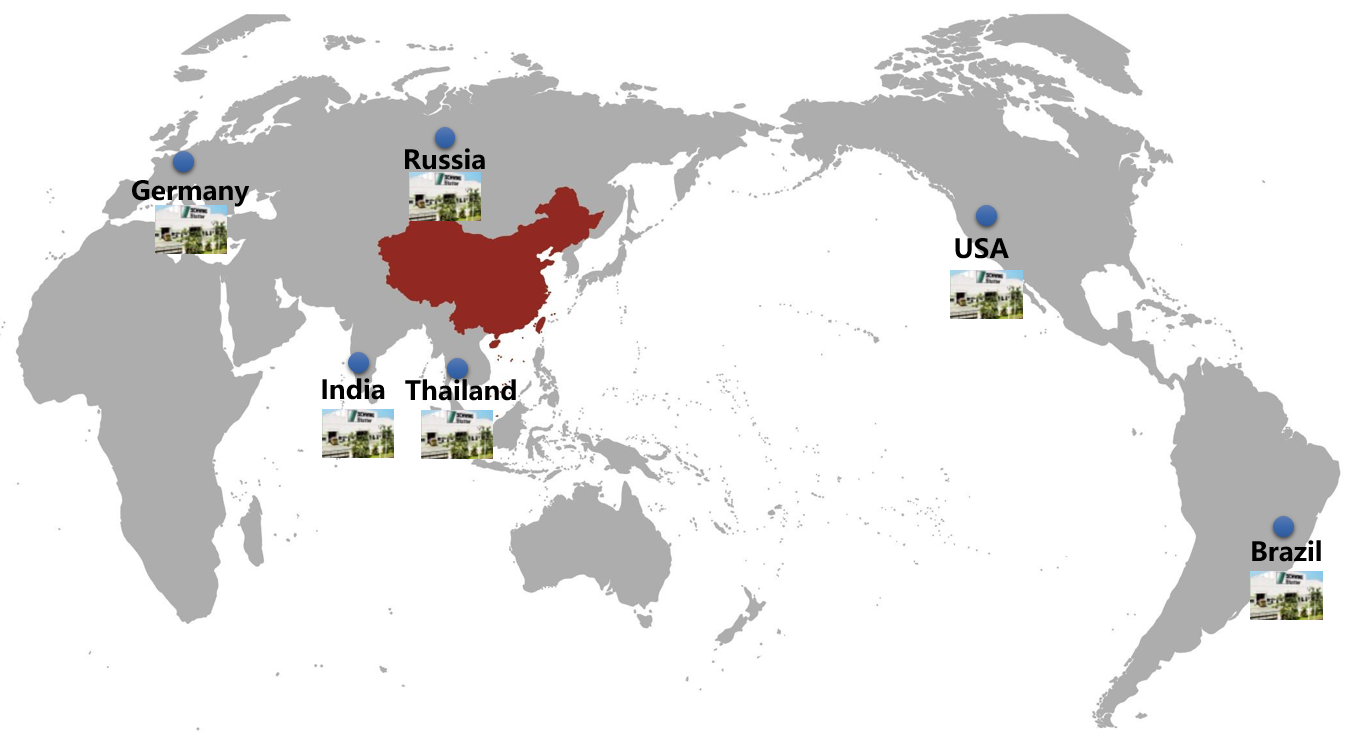

COMPANY PROFILE

Hangzhou Chenlong Intelligent Technology Co., Ltd. is a high-tech enterprise dedicated to the development of machine vision inspection, industrial robot application intelligent equipment, laser welding, sales, and services. The company has a doctoral innovation station and a Hangzhou R&D center, with over 40 scientific research personnel. It

is open to cooperation with domestic and foreign higher education institutions such as Xi'an University of Electronic Science and Technology and Zhejiang University of Science and Technology, jointly building an enterprise centered industry university research platform, connecting customer and supplier resources to form strategic alliances, and creating an open scientific and technological innovation ecosystem.

After years of dedicated research and development, the technical team has developed its own core technologies in areas such as dimensional measurement, automated production lines, and laser welding. The relevant technical performance indicators have reached the leading level in China, and more than 100 authorized patents have been obtained. The project has been selected multiple times as the "First Product in Zhejiang Equipment Manufacturing Industry" and the "Machine Replacement" promotion catalog product in Zhejiang Province. The product is currently widely used in industries such as precision manufacturing, semiconductors, integrated circuits, food and drug production, and has been successfully sold to Sany Heavy Industry, Zoomlion Heavy Industry, Yamaha, XCMG Group, etc.

is open to cooperation with domestic and foreign higher education institutions such as Xi'an University of Electronic Science and Technology and Zhejiang University of Science and Technology, jointly building an enterprise centered industry university research platform, connecting customer and supplier resources to form strategic alliances, and creating an open scientific and technological innovation ecosystem.

After years of dedicated research and development, the technical team has developed its own core technologies in areas such as dimensional measurement, automated production lines, and laser welding. The relevant technical performance indicators have reached the leading level in China, and more than 100 authorized patents have been obtained. The project has been selected multiple times as the "First Product in Zhejiang Equipment Manufacturing Industry" and the "Machine Replacement" promotion catalog product in Zhejiang Province. The product is currently widely used in industries such as precision manufacturing, semiconductors, integrated circuits, food and drug production, and has been successfully sold to Sany Heavy Industry, Zoomlion Heavy Industry, Yamaha, XCMG Group, etc.

FEATURES AT A GLANCE

PRODUCT SPECIFICATIONS

|

Model

|

|

AVS-3020 (G)

|

|

|

Range X*Y axis (mm)

|

|

300*200*200

|

|

|

Maximum load of workpiece (kg)

|

|

25

|

|

|

Raster scale resolution (μm)

|

|

0.5

|

|

|

Measurement accuracy (μm)

|

|

3.0+L/200

|

|

|

SENSOR

|

|

High definition digital industrial camera

|

|

|

LENS

|

|

High-definition manual 0.7X-4.5X zoom lens with detent

|

|

|

Magnification rate

|

|

28X-180X

|

|

|

Light source

|

Upper surface light

|

Annular LED cold light source with adjustable brightness

|

|

|

|

Lower wheel profile light

|

Circular LED cold light source with adjustable brightness

|

|

|

Measuring software

|

|

Customized manual measurement software

|

|

|

Overall dimensions (mm)

|

|

1300*800*1700

|

|

|

Instrument weight (kg)

|

|

280

|

|

|

Power supply

|

|

AC220±10% 50Hz

|

|

|

Suggested work enviroment

|

|

Temperature 20±2℃,humidity 45%-75%,vibration <0.002g,below 15Hz

|

|

SALES AND SERVICE NETWORK

Successful Project

Project in Thailand

Project in India

Project in Russia

EQUIPMENT DETAILS :

SIMILAR PRODUCTS

INTERNAL FACTORY DIAGRAM

PACKAGING &SHIPPING

Detachable wooden box

Sea and land transportation

Sea and land transportation

SERVICE

Pre sales:

We provide free consulting services, and customers provide product testing requirements. Our professional technical team conducts laboratory tests and evaluates them before recommending the most suitable testing plan to customers.

On sale:

On sale:

Provide solutions such as standard testing equipment, some non-standard micro customized equipment, and all non-standard private customized equipment according to different testing needs.

After sales:

After sales:

Provide professional technical training and provide targeted teaching based on product characteristics. Such as on-site teaching, offline video teaching, online one-on-one telephone teaching, and video teaching.

FAQ

INSTRUMENT CHARACTERISTICS

1.Granite base and column ,with strong rigidity ,small deformation,high accuracy,and good stability.

2. Adapting Taiwan precision guide screw,three-axis fully closed-loop servo control.

3.The three-axis adopts high-precision linear guide rails from Taiwan to ensure machine accuracy and service life.

4.High definition digital industrial camera ,achieving high-definition precision measurement of products and z-axis optical height measurement.

5.Can import and export DXF files,compare drawing with physical inspection results.

6.Measurement data can be quickly exported to Word,Excel Auto CAD,and can be quickly photographed.

SELLING POINTS:

Can achieve one click automatic detection.

Support customization, upgrade and add probes to measure 3D stereo features, and use probes of different shapes to achieve multi-directional detection.

The visual and probe structure functions complement each other's advantages and disadvantages. The probe compensates for three-dimensional features that cannot be detected by vision. Vision can detect small holes and thin parts that cannot be detected by the probe, improving the slow speed of point extraction when detecting the contour of open and closed curves.

FEATURES :

Low cost, high precision, high efficiency, and easy operation

FUNCTION:

With multiple functions such as one click automatic detection, automatic capture, automatic boundary judgment, intelligent filtering, and automatic export of detection results, it is suitable for measuring various batches, types, and complex shapes of products.

Probe size detection content:

After upgrading and adding probes, 3D three-dimensional features can be measured, and with probes of different shapes, multi-directional detection can be achieved. It is mainly used for detecting parts with thickness and inner space greater than 5mm.

1. Coordinate detection of points

2. Length, straightness, parallelism, inclination, and perpendicularity detection of lines.

3. Detection of diameter, radius, roundness, and center coordinates of circles and arcs

4. Size and angle detection of rectangles and polygons

5. Ring concentricity detection

6. Contour detection of open and closed curves

7. Surface flatness, surface to line (including axis, centerline, etc.), surface to surface distance, parallelism, verticality,

inclination, and symmetry detection

8. Diameter and cylindricity of cylinders, coaxiality between cylinders and circular holes

Visual size detection content:

7. Surface flatness, surface to line (including axis, centerline, etc.), surface to surface distance, parallelism, verticality,

inclination, and symmetry detection

8. Diameter and cylindricity of cylinders, coaxiality between cylinders and circular holes

Visual size detection content:

When the product is horizontally placed, the dimensions of the elements on the upper surface are detected using 2D planar features, which are often used for detecting parts with thinner thickness.

1. Coordinate detection of points

2. Detection of line length, straightness, parallelism, inclination, and verticality

3. Diameter, radius, roundness of circles and arcs, and coordinate detection of the center of the circle

4. Size and angle detection of rectangles and polygons

5. Ring concentricity detection

6. Contour detection of open and closed curves.

Application Scenarios :

Machinery, electronics, motors, mobile phones, cutting tools, hardware, fasteners, bearings, gears, molds, stamping parts, injection molding, rubber, low-voltage electrical appliances, connectors, terminals, automotive parts, power batteries, railway transportation, ships, aerospace, nuclear industry, medical equipment, instruments and meters, etc.

Hot Searches