- Product Details

- {{item.text}}

Quick Details

-

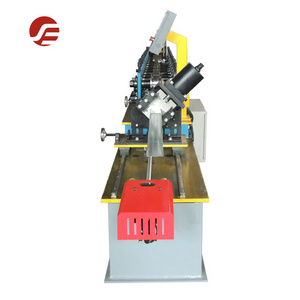

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SUHANG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Working speed:

-

15-20m/min

-

Basic frame:

-

H350 steel

-

Color:

-

Blue or customized

-

Certification:

-

CE ISO

-

Feature:

-

Easy operation

-

Advantage:

-

Long working life

-

Type:

-

Automatic

-

Spare parts:

-

Imported brands

-

Roller material:

-

GCr15

Quick Details

-

Weight (KG):

-

6.5

-

Marketing Type:

-

Hot Product 2021

-

Core Components:

-

PLC

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SUHANG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Working speed:

-

15-20m/min

-

Basic frame:

-

H350 steel

-

Color:

-

Blue or customized

-

Certification:

-

CE ISO

-

Feature:

-

Easy operation

-

Advantage:

-

Long working life

-

Type:

-

Automatic

-

Spare parts:

-

Imported brands

-

Roller material:

-

GCr15

|

No.

|

Item

|

Parameter

|

|

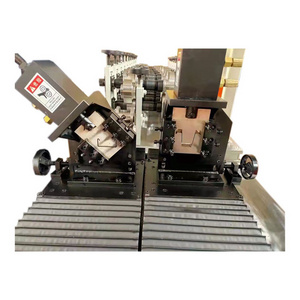

1

|

Coil material

|

0.6-0.8 mm steel(according to customer's request)

|

|

2

|

Rollers material

|

Gcr15 bearing steel, quenching (HRC55-58)

|

|

3

|

Shaft material

|

45#forge steel, thermal fining

|

|

4

|

Cutting blade

|

Cr12Mov, heat treatment(HRC58-62°)

|

|

5

|

Driving method

|

by chain

|

|

6

|

Working speed

|

8-15 m/min

|

|

7

|

Dimension

|

about 10*1.0*1.5 m (length*width*height)

|

|

8

|

Weight/ Container

|

about 6.5T/ one 40'GP

|

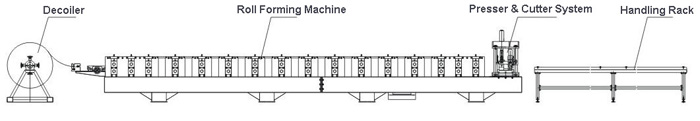

Working process

Decoiler--guiding--roll forming--hydraulic cutting--out table

|

No.

|

Component

|

Quantity

|

|

1

|

Decoiler

|

1 set

|

|

2

|

Guiding

|

1 set

|

|

3

|

Roll forming

|

1 set

|

|

4

|

Hydraulic cutting

|

1 set

|

|

5

|

Out table

|

2 sets

|

|

6

|

Hydraulic station

|

1 set

|

|

7

|

PLC controller

|

1 set

|

|

8

|

Spare part&tools

|

1 box

|

Q1.

Are you trading company or factory?

A1. We’re manufacturer, not just foreign trade company. We have a factory.

A1. We’re manufacturer, not just foreign trade company. We have a factory.

Q2.

Why is your price higher than other suppliers’?

A2. Our machines use imported brands and domestic first-tier brands with fine workmanship, reasonable design. The price also varies according to different speed and structure.

A2. Our machines use imported brands and domestic first-tier brands with fine workmanship, reasonable design. The price also varies according to different speed and structure.

Q3.

Do your machines have good quality?

A3. Definitely yes. We pay high attention to quality. We have many regular customers domestic and abroad. We think only high quality machines will gain long-term cooperation with customers.

A3. Definitely yes. We pay high attention to quality. We have many regular customers domestic and abroad. We think only high quality machines will gain long-term cooperation with customers.

Q4.

What information customers need to provide if they want to get the quotation?

A4. Customers need to provide us with profile drawing with exact specifications, material, material’s thickness and punching holes.

A4. Customers need to provide us with profile drawing with exact specifications, material, material’s thickness and punching holes.

Q5.

Can you make customized profile machines?

A5. Yes, we can design the machines according to customers’ needs

A5. Yes, we can design the machines according to customers’ needs

Q6.

Do you have after-sales service?

A6. Definitely yes. We’ll provide one year free after-sales service. Even after one year, we can also support you when the machines have problems. We’ll charge only when some spare parts need to be changed.

A6. Definitely yes. We’ll provide one year free after-sales service. Even after one year, we can also support you when the machines have problems. We’ll charge only when some spare parts need to be changed.

Q7.

How can we trust you can make the machine?

A7. First, we won’t accept the order if we can’t make the machine. We’ll lose than customers if we fail. Second, all our machines need to be checked before delivery. Customers can arrange their friend or the inspection service to come to our factory to inspect the machine.

A7. First, we won’t accept the order if we can’t make the machine. We’ll lose than customers if we fail. Second, all our machines need to be checked before delivery. Customers can arrange their friend or the inspection service to come to our factory to inspect the machine.

Hot Searches