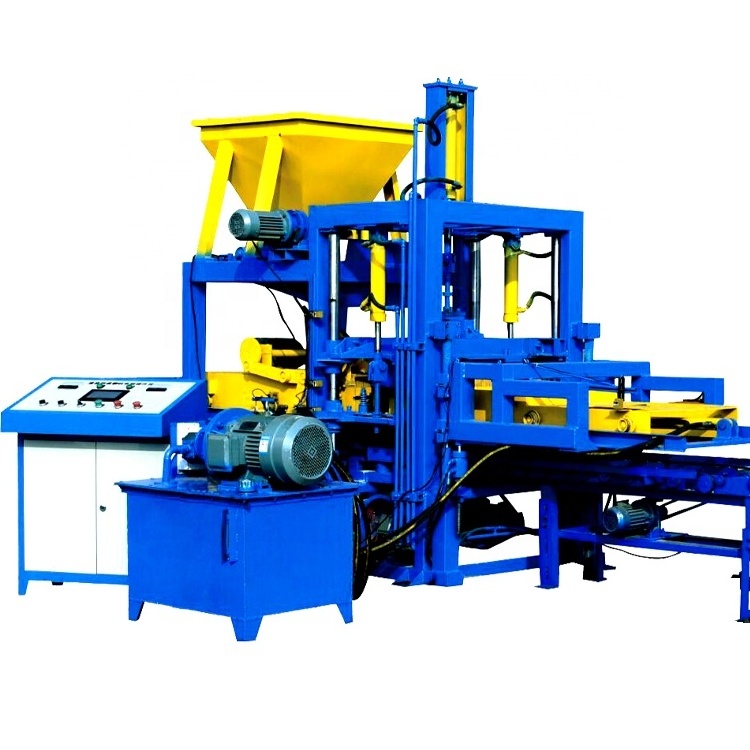

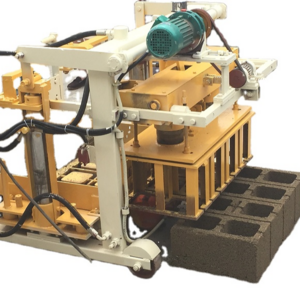

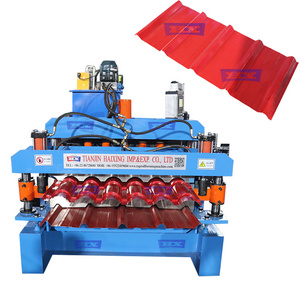

-----Automatic interlock system, high safe operation performance

-

-----The formula is automatically saved for convenient operation and high efficiency

------Electro-hydraulic integrated technology, fault alarm system