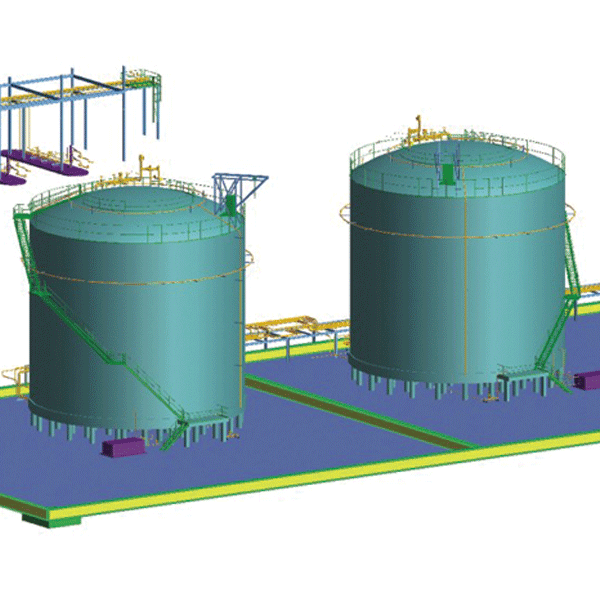

With the development of the LNG industry, LNG storage has become increasingly large-scale and atmospheric pressure. The domestic design and manufacturing have reached 50,000 m3, and a single atmospheric pressure storage tank with 250,000 m3 and 160,000 m3LNG has been established in the coastal area. At present, the LNG storage tanks designed, manufactured and installed in China are mainly 5000m3 and 10000m3, which are widely used in LNG liquefacturing plants or LNG peaking stations. The amount of LNG produced by industrial exhaust gas is generally relatively small, and LNG storage tanks of about 1000m3 are commonly used.

- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product This Year

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

GreenFir

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

9600000

-

Storage medium:

-

For LNG, liquefied hydrocarbons or liquid ammonia storage tanks

-

Categories:

-

Single capacity tank, Double capacity tank, Full capacity tank

-

Scope of application:

-

Cylindrical container, rectangular container

-

Design pressure:

-

-0.02MPa< P ≤0.05MPa

-

Design temperature:

-

-196℃ < T ≤ 0℃

-

Definition summary:

-

Steel vertical cylindrical above ground storage tank

Quick Details

-

Capacity:

-

20000m3

-

Applicable Industries:

-

Natural Gas Plant, Air Separation Plant

-

Max Working Pressure(MPa):

-

0.05 MPa

-

Marketing Type:

-

New Product This Year

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

GreenFir

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

9600000

-

Storage medium:

-

For LNG, liquefied hydrocarbons or liquid ammonia storage tanks

-

Categories:

-

Single capacity tank, Double capacity tank, Full capacity tank

-

Scope of application:

-

Cylindrical container, rectangular container

-

Design pressure:

-

-0.02MPa< P ≤0.05MPa

-

Design temperature:

-

-196℃ < T ≤ 0℃

-

Definition summary:

-

Steel vertical cylindrical above ground storage tank

About Us

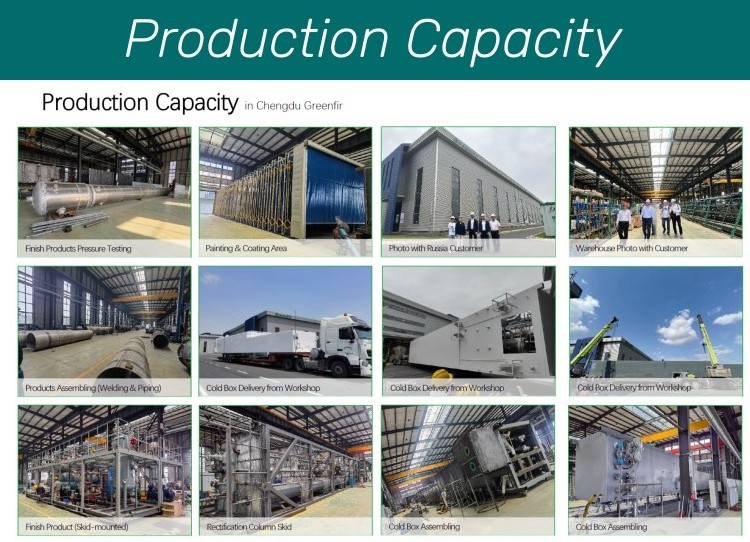

Greenfir is a professional natural gas processing, liquefaction plant, air separation unit, heat exchanger, reciprocating piston compressor, cryogenic cold box, fractionating column manufacturer and solutions provider with ISO 9001: 2015, ISO 14001: 2015, ISO45001: 2018 and ASME U certified.

Greenfir has successfully designed, manufactured and delivered more than 300 sets of natural gas purification, liquefication plants, air separation units, CNG filling stations, cryogenic cold box, etc. all-around China, Middle East, Central Asia and Southeast Asia, etc. We can deliver skid-mounted solutions customized to meet client's challenges and requirements (including adverse weather conditions, transportation and plot area limitations, etc.).

We treat all the cryogenic solutions with serious attitudes and professional experience. Combined with our knowledge and experience, Greenfir provides each client with a technology-leading solution you can count on and bring a wider range of options and more profits.

Greenfir has successfully designed, manufactured and delivered more than 300 sets of natural gas purification, liquefication plants, air separation units, CNG filling stations, cryogenic cold box, etc. all-around China, Middle East, Central Asia and Southeast Asia, etc. We can deliver skid-mounted solutions customized to meet client's challenges and requirements (including adverse weather conditions, transportation and plot area limitations, etc.).

We treat all the cryogenic solutions with serious attitudes and professional experience. Combined with our knowledge and experience, Greenfir provides each client with a technology-leading solution you can count on and bring a wider range of options and more profits.

Product Description

Atmospheric Pressure Cryogenic Liquid Storage Tank

Performance Characteristics

Bimetal full-capacity tank ceiling structure has the following

advantages

:

①The full-capacity tank structure ensures that in the case of leakage of the inner tank, the outer tank can effectively store part of the liquid, and the evaporated gas is recovered through the recovery pipeline or to the torch.

② The full-capacity tank structure according to the requirements of the code has less fire spacing and high land utilization rate.

③The inner tank design does not need to consider the internal positive pressure and sandwich vacuum load, and the inner tank is not affected by any overpressure or vacuum accident in the storage tank.

④ The ceiling structure nozzle does not need to consider the compensation of the pipe in the sandwich. For the inner tank of the arch structure, both ends of the pipeline are firmly connected with the inner tank and the outer tank, while for the suspended ceiling tank, only one end of the pipeline is fixed to the top of the outer tank, and the other end can be freely retractable.

Performance Characteristics

It is composed of double metal wall, flat bottom, inner suspended roof, outer arch roof, vertical cylinder and fully inclusive

structure. It is composed of main container, secondary container, bottom insulation, sandwich insulation, ceiling insulation, top

steel structure of storage tank, tower ladder, equipment valve, electrical instrument and foundation platform.

structure. It is composed of main container, secondary container, bottom insulation, sandwich insulation, ceiling insulation, top

steel structure of storage tank, tower ladder, equipment valve, electrical instrument and foundation platform.

Configuration Parameter

|

Volume m

3

|

200

|

500

|

1000

|

2000

|

5000

|

10000

|

20000

|

50000

|

|||||||

|

Inner tank size

|

Φ6500×6890

|

Φ9000×8922

|

Φ12400×14235

|

Φ13500×15750

|

Φ20000×19415

|

Φ25000×22000

|

Φ38000×20000

|

Φ50000×38600

|

|||||||

|

Outer tank size

|

Φ8800×9300

|

Φ11200×10350

|

Φ13000×14805

|

Φ16000×18500

|

Φ22400×21870

|

Φ27000×28930

|

Φ40000×29760

|

Φ52000×38600

|

|||||||

|

Note

|

Can design, manufacture and install storage tanks of any size between 200 - 50000 m3 according to the needs of users.

|

|

|

|

|

|

|

|

|||||||

Product Parameters

200 m3 ~ 50,000

m3

Note:

Note:

1. The equipment's technical parameters are subject to the final design.

2. The thermal insulation of the equipment is made of pearlescent sand + elastic felt + foam glass brick + thermal insulation cotton.

Hot Searches