- Product Details

- {{item.text}}

Quick Details

-

Power:

-

8KW

-

Dimension(L*W*H):

-

2250*1240*1900mm

-

Weight:

-

2500 kg

-

Product name:

-

Paper cup forming machine

-

Model:

-

HF-ZBJ-120

-

Color:

-

Customerized

-

For the paper:

-

150-380g/m²

-

voltage:

-

380 v50hz or custom

-

Paper cup size:

-

1.5-16 oz

-

General power:

-

8kw

-

After sale Service:

-

Life-long Service

-

Spare parts supply:

-

Lifelong Time

-

Installation:

-

Under Engineer's Guide

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

HANFA

-

Voltage:

-

380V

-

Power:

-

8KW

-

Dimension(L*W*H):

-

2250*1240*1900mm

-

Weight:

-

2500 kg

-

Product name:

-

Paper cup forming machine

-

Model:

-

HF-ZBJ-120

-

Color:

-

Customerized

-

For the paper:

-

150-380g/m²

-

voltage:

-

380 v50hz or custom

-

Paper cup size:

-

1.5-16 oz

-

General power:

-

8kw

-

After sale Service:

-

Life-long Service

-

Spare parts supply:

-

Lifelong Time

-

Installation:

-

Under Engineer's Guide

Products Description

Scope of application

HF-ZBJ-120 automatic medium speed paper cup machine adopts mesa layout, the forming mold and the transmission part is isolated,the transmission is arranged in the frame box under the mesa. The machine has automatic spray lubrication system, using the

combination of longitudinal shaft transmission structure, cylindrical indexing structure and gear transmission. The forming molds are arranged on the table for easy cleaning and maintenance.

Automatic medium speed paper cup machine adopts cylindrical indexing CAM with only one aluminum plate to complete the cup structure, so that the machine speed is faster and the model is smaller. It has photoelectric detection, fault alarm, counting and other functions. Through the automatic transmission of paper feeding, sealing (adhesive cup), oil filling, flushing, turning, heating, krabing, rolling, unloading and other continuous processes, is the ideal equipment to improve the production of beverage cups, tea cups, coffee cups, advertising paper cups, tasting cups, the capacity of 70-90 per minute.

High speed, high efficiency and stability.

combination of longitudinal shaft transmission structure, cylindrical indexing structure and gear transmission. The forming molds are arranged on the table for easy cleaning and maintenance.

Automatic medium speed paper cup machine adopts cylindrical indexing CAM with only one aluminum plate to complete the cup structure, so that the machine speed is faster and the model is smaller. It has photoelectric detection, fault alarm, counting and other functions. Through the automatic transmission of paper feeding, sealing (adhesive cup), oil filling, flushing, turning, heating, krabing, rolling, unloading and other continuous processes, is the ideal equipment to improve the production of beverage cups, tea cups, coffee cups, advertising paper cups, tasting cups, the capacity of 70-90 per minute.

High speed, high efficiency and stability.

Technical Parameter

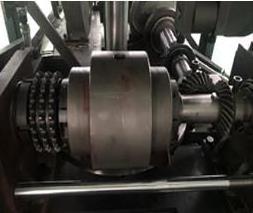

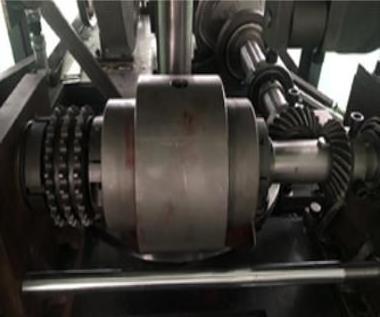

Transmission mechanism

Longitudinal shaft gear transmission, cylindrical dividing CAM V internal layout, to ensure high transmission accuracy synchronization performance, so as to achieve the coordination between the stroke, to avoid interference with moving parts, remove,the chain transmission jitter and transmission is not stable shortcomings.

Open type CAM

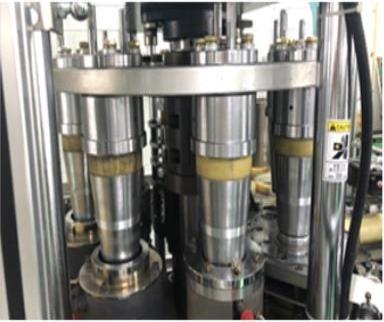

Eight station mould

Ultrasonic suturing

PLC control panel

Paper supply station

Circulating oil pump filtration

If you need Papermaking equipment, please contact us, this is my WhatsApp. Or you can directly click the blue font below to send an inquiry, we will help you make more money. WhatsApp:+8617739786040 E-mail:maichuan@hanfagroup.com

Company Introduction

FAQ

1. Are you a trading company or a manufacturer?

We are a professional manufacturer. Our factory mainly produces water well drilling rigs, core drilling rigs, down-the-hole drilling rigs, pile drivers, etc. The products have been exported to hundreds of countries around the world and enjoy a high reputation all over the world.

2. How is the quality of your machine?

Our products pass strict quality inspections before they leave the factory to ensure that they are qualified before they are shipped.

3. How to inspect the goods?

1) Support customers to come to the factory for on-site inspection.

2) Support customers to designate third-party companies to inspect goods.

3) Support video inspection.

4. Do you have after-sales service?

Yes, we have a dedicated service team that will provide you with professional technical guidance. If you need, we can send our engineers to your workplace and provide training for your employees.

5. How about quality assurance?

We provide a one-year quality guarantee for the main machine of the machine.

6. How long is your delivery cycle?

1) In the case of stock, we can deliver the machine within 7 days.

2) Under standard production, we can deliver the machine within 15-20 days.

3) In the case of customization, we can deliver the machine within 20-25 days.

Hot Searches