- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Jucos

-

Model Number:

-

STD BULK,HPBULK,HZ BULK

-

Application:

-

Industrial kiln

-

Dimensions:

-

STD BULK,HPBULK,HZ BULK

-

Working Temperature:

-

1260-1430

-

Fiber Diameter:

-

3.5um

-

Thermal Conductivity:

-

0.09--0.20

-

Shrinkage (1800℉, 3h):

-

3%(24hours

-

Name:

-

Ceramic fiber bulk

-

Bulk density(Kg/m3):

-

128

-

Specification Temperature ℃:

-

1260

-

Working Temp ℃:

-

1050

-

Shot content (%):

-

≤15

-

Al2O3(%):

-

45

-

SiO2(%):

-

54

-

Fe2O3(%):

-

≤0.5

-

Na2O(%):

-

≤0.2

-

Melting Point:

-

1575

Quick Details

-

Ultimate Strength (≥ MPa):

-

--

-

Density (kg/m³ ):

-

--

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jucos

-

Model Number:

-

STD BULK,HPBULK,HZ BULK

-

Application:

-

Industrial kiln

-

Dimensions:

-

STD BULK,HPBULK,HZ BULK

-

Working Temperature:

-

1260-1430

-

Fiber Diameter:

-

3.5um

-

Thermal Conductivity:

-

0.09--0.20

-

Shrinkage (1800℉, 3h):

-

3%(24hours

-

Name:

-

Ceramic fiber bulk

-

Bulk density(Kg/m3):

-

128

-

Specification Temperature ℃:

-

1260

-

Working Temp ℃:

-

1050

-

Shot content (%):

-

≤15

-

Al2O3(%):

-

45

-

SiO2(%):

-

54

-

Fe2O3(%):

-

≤0.5

-

Na2O(%):

-

≤0.2

-

Melting Point:

-

1575

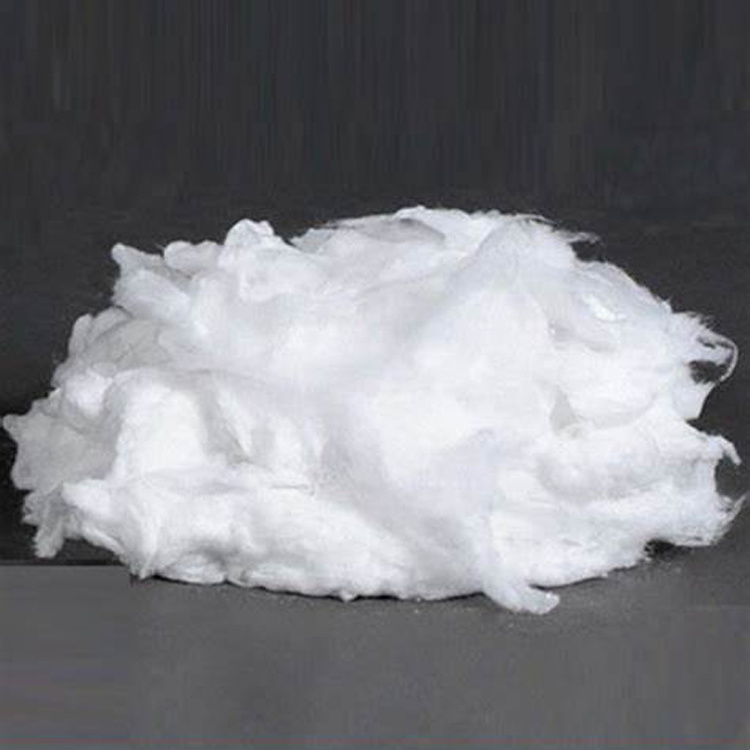

Thermal Insulation Material Wool Good Price Refractory Ceramic Fiber Bulk

As the crucial and staple materials for producing ceramic fiber blanket, board, module and other formed products, ceramic bulk fiber is normally manufactured from high purity raw materials-alumina powder, silica sand through unique production techniques of spun or blowing, these bulks are loose, long and flexible with fine thermal properties, at present, the chopped fibers are vacuum formed production, the lubricated bulk fibers are the fiber for textiles are all available. Ceramic bulk fibers Serve as ab ideal filler for various types of refractory lining and insulation tools.

Features Of Thermal Insulation Ceramic Fiber Bulk

-

Good springiness for fiber

-

Excellent strength and resistance to blowing

-

Excellent chemical stability, resistance to erosion

-

Low thermal conductivity

-

Low thermal shrinkage

-

Excellent sound absorption

Applications Of Thermal Insulation Ceramic Fiber Bulk

-

Filling insulation and joint sealing

-

Back-up lining for industrial furnaces

-

Fireproof materials for construction

-

High temperature materials for filtration

-

Raw materials of fiber Paper and vacuum forming products

-

Raw materials of fiber coating materials

-

Raw materials of fiber castable and coatings

-

High-temperature furnace heating equipment wall lining fillings

-

Raw materials of fiber textile products

Specifications Of Thermal Insulation Ceramic Fiber Bulk

- Alumina contents range from 34% to 44%

- Widely used throughout metallurgical industry

Physical And Chemical Indicators For Thermal Insulation Ceramic Fiber Bulk

|

STD BULK |

HP BULK |

HZ BULK |

||

|

(%) Chemical Composition |

Al2O3 |

≥ 44 |

≥ 45 |

≥ 34 |

|

SiO2 |

≥ 52 |

≥ 54 |

≥ 50 |

|

|

Fe2O3 |

≤ 1.0 |

≤ 0.5 |

≤ 0.5 |

|

|

Na2O |

≤ 1.0 |

≤ 0.2 |

≤ 0.2 |

|

|

ZrO2 |

- |

- |

≥ 15 |

|

|

Specification Temp. ( ℃ )

|

1260 |

1260 |

1430 |

|

|

Shot content (%) |

≤ 15 |

≤ 15 |

≤ 12 |

|

|

Fiber Diameter(μ m) |

3.5 |

|||

Pictures Of Thermal Insulation Ceramic Fiber Bulk

As the crucial and staple materials for producing ceramic fiber blanket,board,module and other formed products,ceramic fiber bulk is normally manufactured from high purity raw materials-alumina powder,silica sand through unique production techniques of spun or blowing,these bulks are loose,long and flexible with fine thermal properties,at present,the chopped fibers are vacuum formed production,the lubricated bulk fibers are the fiber for textiles are all available.Cotton Stuffing Fiber serve as ideal filler for various types of refractory lining and insulation tools.

Specification

Packaging & Shipping

25kg woven bag or carton package,as customer request