- Product Details

- {{item.text}}

Quick Details

-

Type:

-

Seed Cleaning and Separating Machine

-

Use:

-

Seed Cleaning and Separating

-

Production Capacity (kg/h):

-

10000 - 100000

-

Sieve Size(mm):

-

decided by model

-

Power (kW):

-

decided by model

-

Weight:

-

1700 KG

-

Color:

-

Customized

-

Raw material:

-

Carbon Steel

-

Application:

-

Maize, Corn, Wheat, Sesame, Quinoa , Cassia Seed

-

Power:

-

220-680V

-

Function:

-

grain cleaning

-

Spare parts:

-

one year

-

Discount:

-

yes

-

After-sales Service Provided:

-

Field maintenance and repair service

-

After Warranty Service:

-

Video technical support

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LONGTAI

-

Dimension(L*W*H):

-

decided by model

-

Type:

-

Seed Cleaning and Separating Machine

-

Use:

-

Seed Cleaning and Separating

-

Production Capacity (kg/h):

-

10000 - 100000

-

Sieve Size(mm):

-

decided by model

-

Power (kW):

-

decided by model

-

Weight:

-

1700 KG

-

Color:

-

Customized

-

Raw material:

-

Carbon Steel

-

Application:

-

Maize, Corn, Wheat, Sesame, Quinoa , Cassia Seed

-

Power:

-

220-680V

-

Function:

-

grain cleaning

-

Spare parts:

-

one year

-

Discount:

-

yes

-

After-sales Service Provided:

-

Field maintenance and repair service

-

After Warranty Service:

-

Video technical support

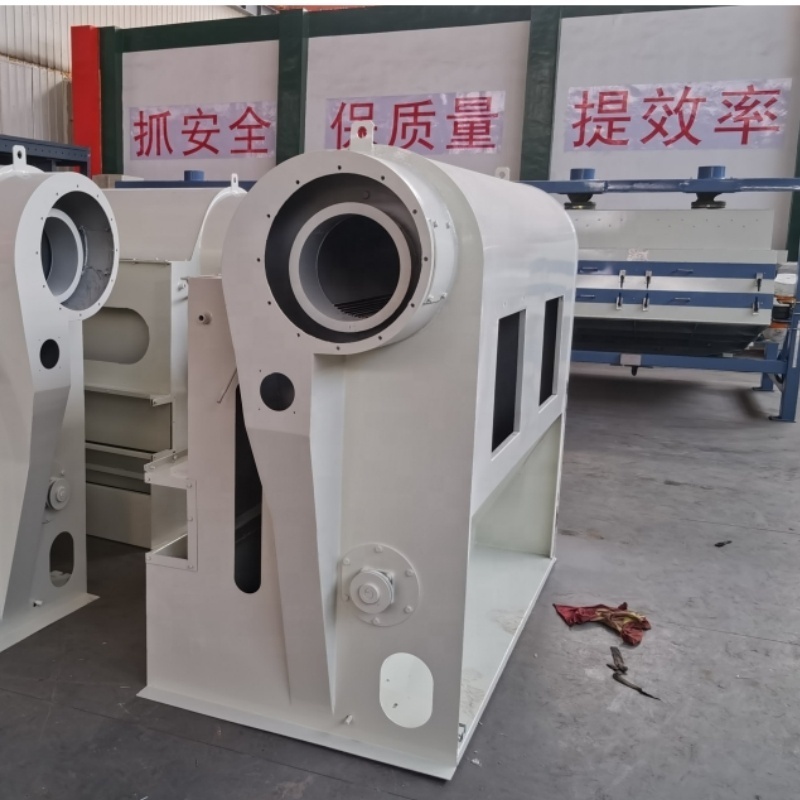

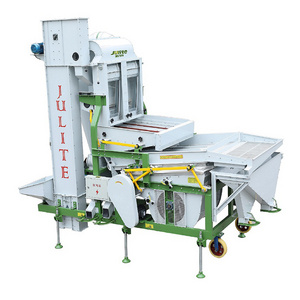

Best Quality seed grain cleaning and sorting machine for sesame soybean chia quinoa maize paddy peanut

Vibratory cleaning SIEVE is mainly used for screening, separating large, medium, small and light impurities mixed in the grains, which can be widely used in milling, feed, rice milling, winery, chemical factory, food, oil extracting, corn processing and other industries to clean and grade raw material. This equipment has the advantages of low noise, stable operation, high processing capacity, less energy consumption, good cleaning effect, excellent sealing effect without dust outside. Use it together with winnowing machine for better efficacy.

Materials of design,

1. The screen body is welded by SPCC (high quality cold-rolled steel plate with standard thickness 3mm).

2. The screen frame is made of steel, with at least ten years’ service life.

3. The screen deck is made of finest manganese plate and stainless steel screen mesh which can be customized.

Treatment of Exterior ,

1. All the frames have been chemically processed: acid pickling, phosphating, and anti-rust treatment.

2. Anti-corrosive primer has been sprayed firstly, then finishing coating adopts famous high quality fade-proof stoving varnish.

3. The surface is glossy, firm and not easy to fade or drop, with strong scratch-proof ability.

Technical Parameters ,

| Types |

Output (wheat) t/h |

Power kw |

Amplitude mm |

Screen gradient ∠ |

Screen size (W*L) |

The dimension of whole machine (L*W*H) |

| TQLZ100*200 | 15~20 | 2.99 | 4.5-5.5 | 8-12 | 1000*2000 | 3450*1850*1862 |

| TQLZ150*200 | 30~40 | 5.25 | 4.5-5.5 | 8-12 | 1500*2000 | 3500*2500*1962 |

| TQLZ180*200 | 50~60 | 5.25 | 4.5-5.5 | 8-12 | 1800*2000 | 3500*2800*1962 |

| TQLZ200*200 | 50~80 | 7.35 | 4.5-5.5 | 8-12 | 2000*2000 | 3500*3000*1875 |

| TQLZ150*270-3C | 50~80 | 8.15 | 4.5-5.5 | 15 | 1500*2700 | 4100*2500*2580 |

\

1. Our Expert give you professional pre-service for your consultation , and proving system evaluation to give you a best solution for your demand .

2. We have set up atechnology & installation & sale department to design , install and test run the production line you need .

3. We insist on " train before sale , service after sale " all the time , so we provide producing , management , maintenance training andytime if the customers needed .

4. We provide high-quality original accessories by sending the accessories to the service network to promise the high speed and efficient after sale service .

5. We guarantee that we'll visit out customers regularly to solve all the problems happened when producing .