- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YUXI

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3000*1600*2000 mm

-

Power (kW):

-

22

-

Weight (T):

-

3.5

-

Applicable Industries:

-

Shredder

-

Diameter Rotary:

-

255mm

-

Rotate the numberof knives:

-

26

-

Rotate the cutter shaft speed:

-

82rpm

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Max.Production Capacity (kg/h):

-

1000

-

Place of Origin:

-

Henan, China

-

Production Capacity (kg/h):

-

500 - 650 kg/h

-

Brand Name:

-

YUXI

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3000*1600*2000 mm

-

Power (kW):

-

22

-

Weight (T):

-

3.5

-

Applicable Industries:

-

Shredder

-

Diameter Rotary:

-

255mm

-

Rotate the numberof knives:

-

26

-

Rotate the cutter shaft speed:

-

82rpm

-

Marketing Type:

-

Ordinary Product

Products Description

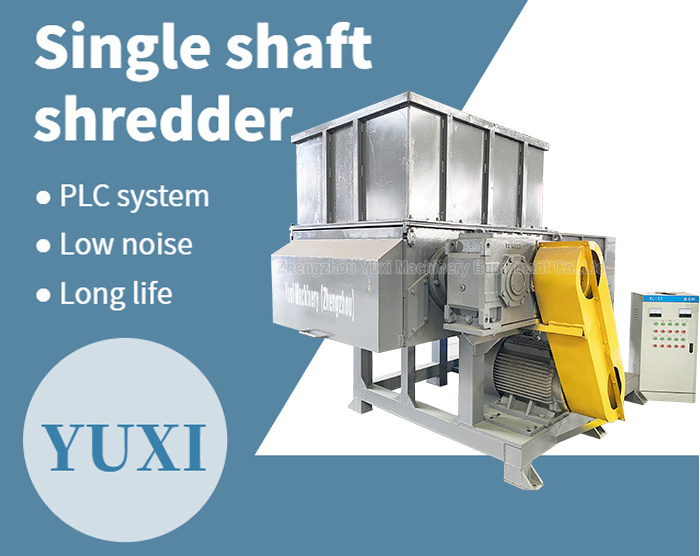

Single Shaft Shredder

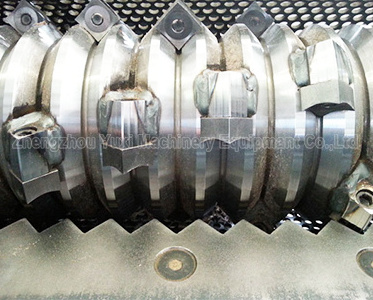

The single shaft shredder is mainly composed of a moving knife roller (spindle + blade), fixed knife, carrying box, box support, feeding system, hydraulic pushing system, power system, and an electrical control system.

The shredder machine is used to crush all kinds of waste materials. When working, a small amount of light and thin metal objects are allowed in the materials. Material size can be adjusted according to the size of the screen aperture

Technical Parameter

|

Shredder Mode

|

YX-A600

|

YX-A800

|

YX-A1000

|

YX-A1200

|

YX-A1500

|

|

Diameter Rotary

|

255mm

|

255mm

|

255mm

|

300mm

|

300mm

|

|

Rotate the numberof knives

|

26

|

45

|

58

|

71

|

88

|

|

Rotate the cutter shaft speed

|

82rpm

|

90rpm

|

87rpm

|

87rpm

|

87rpm

|

|

Number of fixed knlves

|

1

|

2

|

2

|

2

|

2

|

|

Hydraulic power

|

2.2kw

|

3kw

|

5.5kw

|

5.5kw

|

7.5kw

|

|

Working pressure

|

6-12Mpa

|

6-12Mpa

|

6-12Mpa

|

6-12Mpa

|

6-12Mpa

|

|

Crusher capacity

|

250-400kg/h

|

250-450kg/h

|

300-600kg/h

|

500-1000kg/h

|

600-1200kg/h

|

|

Feeding caliber

|

600mm*950mm

|

800mm*950mm

|

1000mm*1000mm

|

1200mm*1100mm

|

1500mm*1250mm

|

|

Power f main motor

|

22kw

|

37kw

|

55kw

|

75kw

|

45*2kw

|

|

Host weight

|

3500kg

|

4500kg

|

6000kg

|

8000kg

|

9500kg

|

|

External dimension

|

3000*1600*2000mm

|

3300*1800*2400mm

|

3850*2000*2700mm

|

4000*2200*2800mm

|

4500*2500*2800mm

|

|

Maximum yield

|

650kg/h

|

900kg/h

|

1000kg/h

|

1200kg/h

|

1500kg/h

|

Application

Plastic products

: plastic heads, nozzles, scraps of plastic products, plastic pipes, plastic sheets;

Waste plastic recycling

: waste film, agricultural film, mulch film, PP woven bag, PET bottle;

Metal recycling

: aluminum, cans, scrap metal, circuit boards, cables and wires;

Waste paper

: paper scraps, books, industrial waste paper;

Wood processing

: wood, wooden pallets, wood, branches, building templates;

Electronic waste

: transformer, plug, data cable

The finished product of the single shaft shredder is between 5-10mm, the shredded product is for your reference

Working Process

The material enters the shredding box through the feeding system. The box carries the moving knife roller and the shredding blade. The oil cylinder pushes the pushing box to push the material near the blade.

The deceleration motor drives the knife roller to rotate, and the material is shredded into small pieces by the combined effect of tearing, squeezing, and shearing by the shredding blade and discharged from the screen hole.

Feature

•The moving knife adopts DC53 material, and the hardness reaches HRC60 ± 1.

• The fixed knife is made of D2 material and its hardness reaches HRC60 ± 1.

• The main electrical components are Siemens and Schneider brands.

• Automatic overload protection to avoid machine overload and seizure.

• Designed with split bearing housing technology, which can change blades quickly and efficiently

• Two-speed hydraulic system, air-cooled device is standard

Customer Photos

Related Product

Hot Searches